Objective table device and dragon gate style objective table device, controlling means of objective table device

A control method and stage technology, applied in the direction of using feedback control, feeding device, automatic control device, etc., can solve problems such as difficulty in ensuring beam parallelism, difficulty in high precision, accuracy error of ball screw mechanism, etc., to eliminate Accuracy variation, burden reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

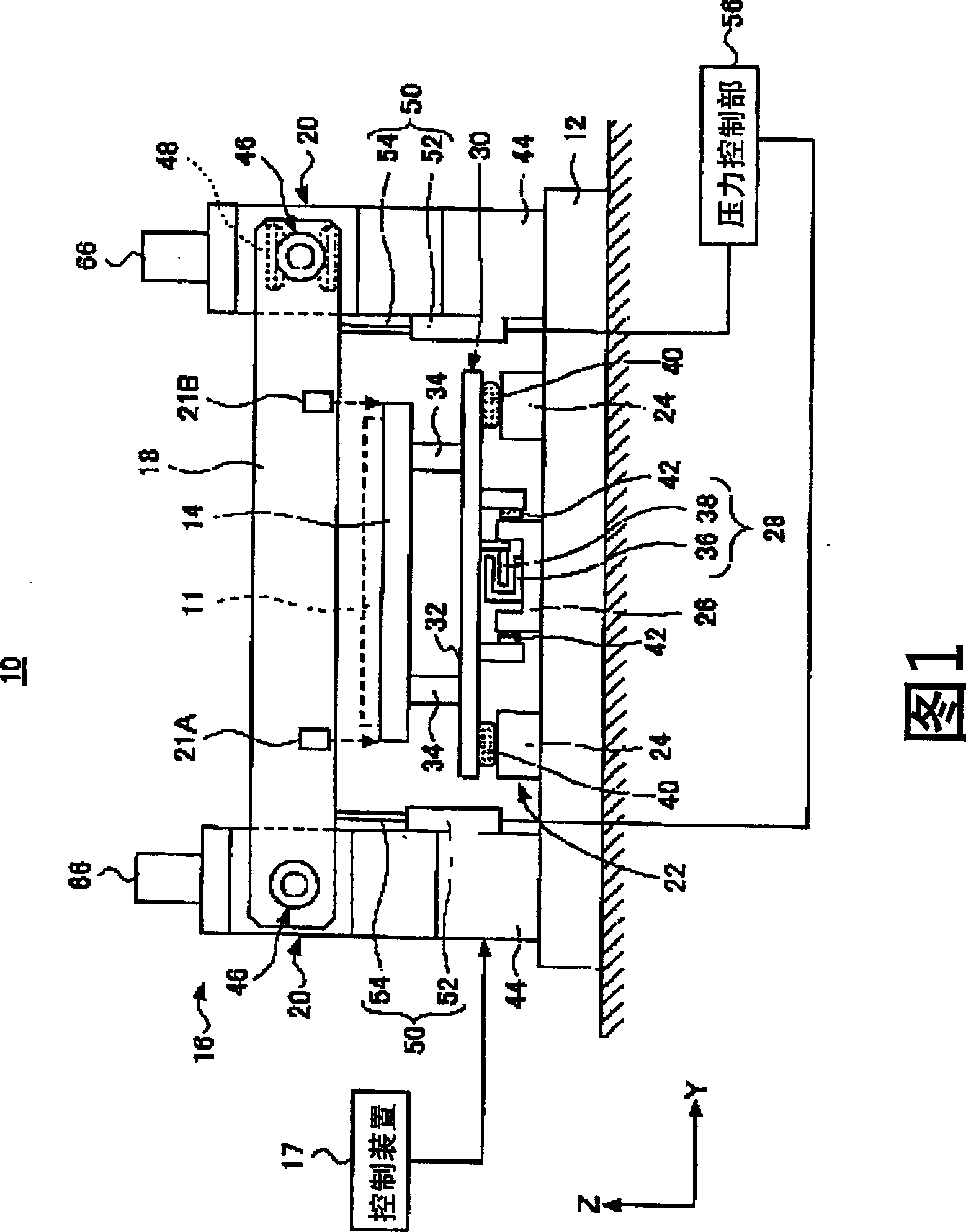

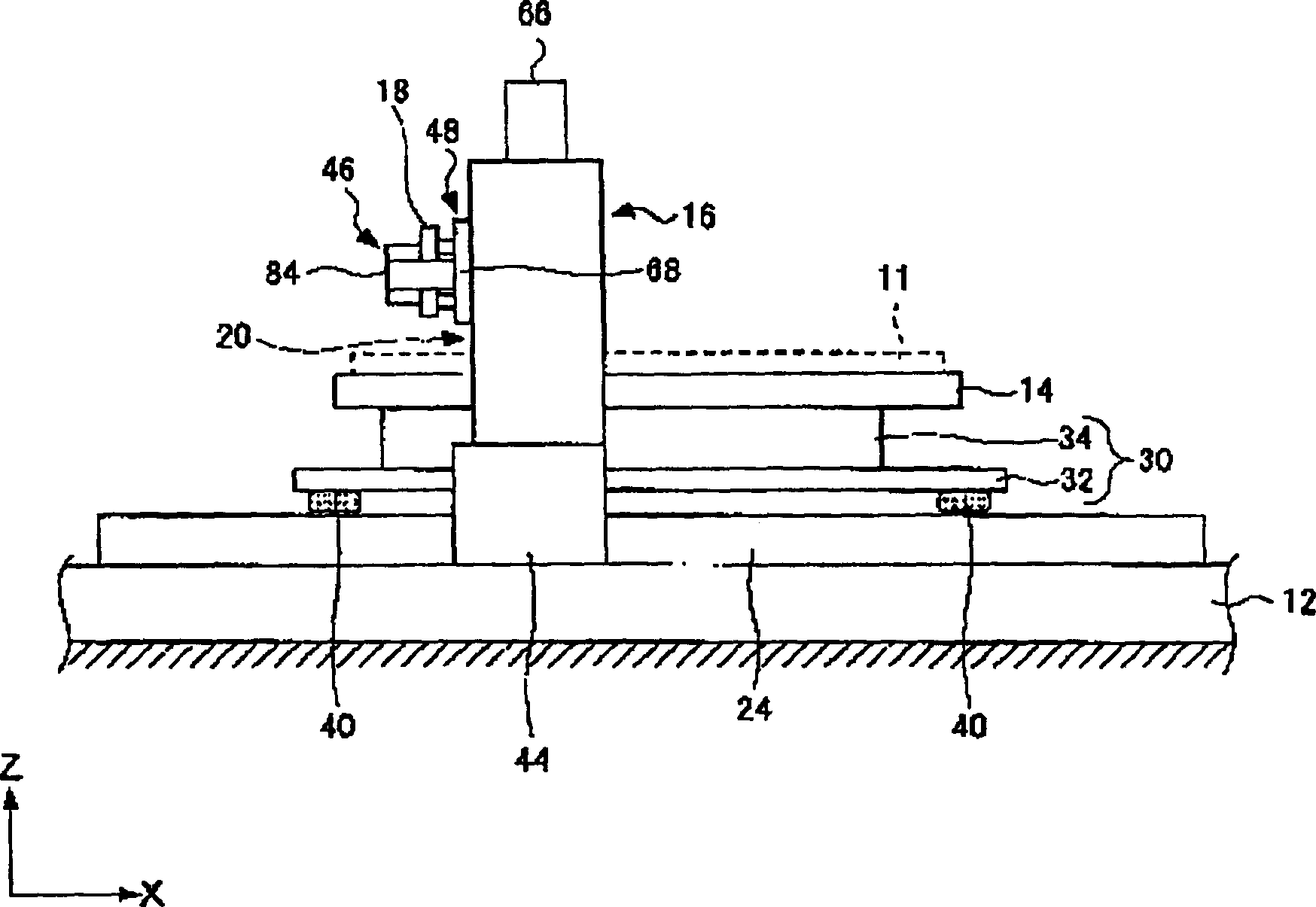

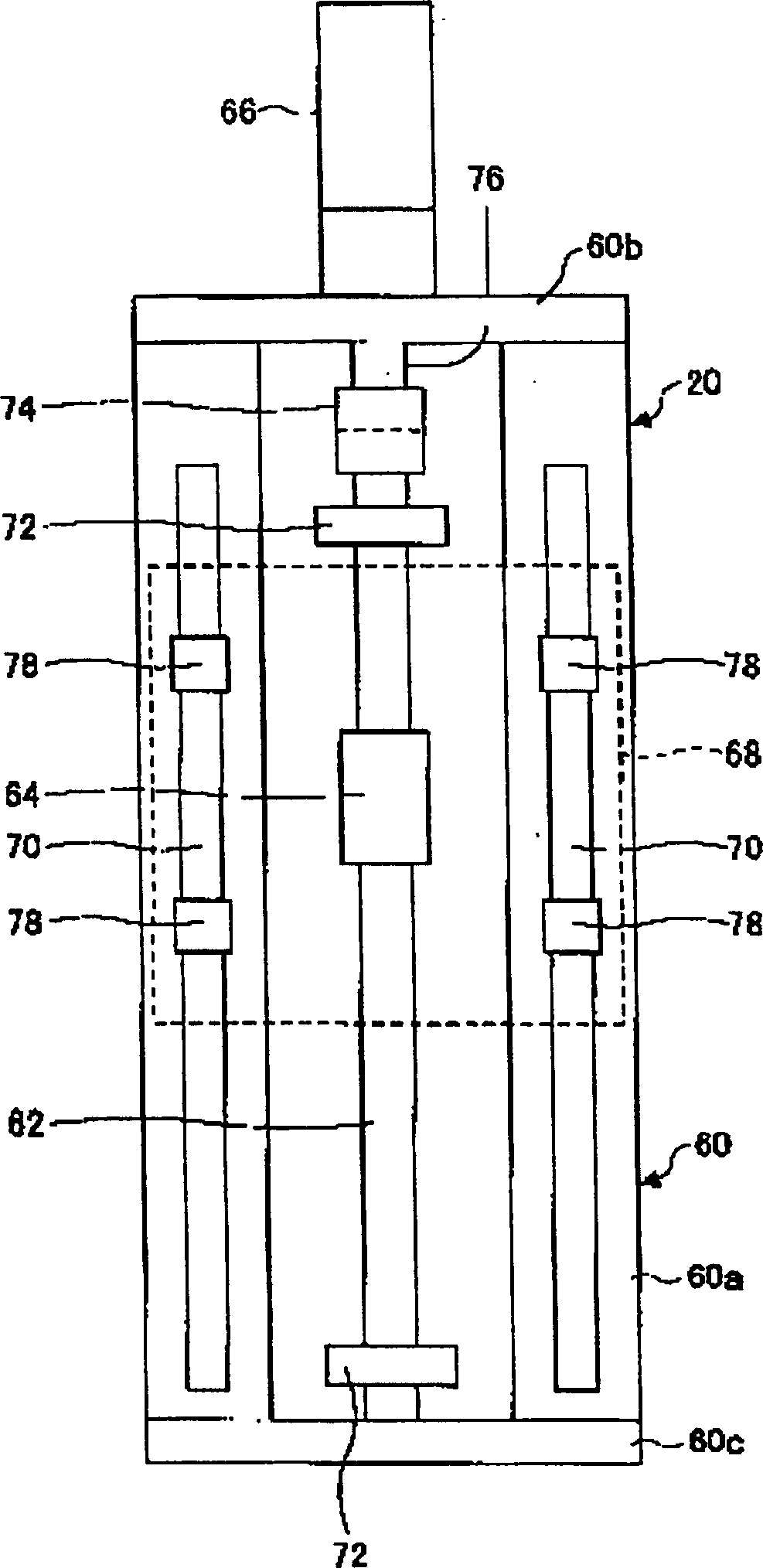

[0038] figure 1 It is a front view showing an embodiment of the stage device of the present invention. figure 2 It is a side view of the stage device. Such as figure 1 and figure 2 As shown, the stage device 10 is a so-called gantry-type stage device that moves a substrate (shown by a dotted line in the figure) 11 as a workpiece in the horizontal direction. Direction The workbench 14 movably arranged on the base 12, the door-shaped gantry part 16 fixed on the base 12, the movement of the workbench 14 along the Y direction and the height adjustment control of the gantry part 16 in the Z direction The control device (control unit) 17.

[0039] The upper surface of the workbench 14 is a placement surface for placing the substrate 11 . And, be provided with the aperture (not shown) of a plurality of vacuum adsorption substrates 11 on the top of workbench 14, suck the air in the gap between substrate 11 and substrate 11 with vacuum pump from apertures. Tight in a horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com