Tool mounting device for turning center

一种安装装置、工具的技术,应用在工具夹、车削设备、车床等方向,能够解决不能实现无液压化、车削加工中心困难、不能实现节能和节省资源等问题,达到节省资源、实用性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

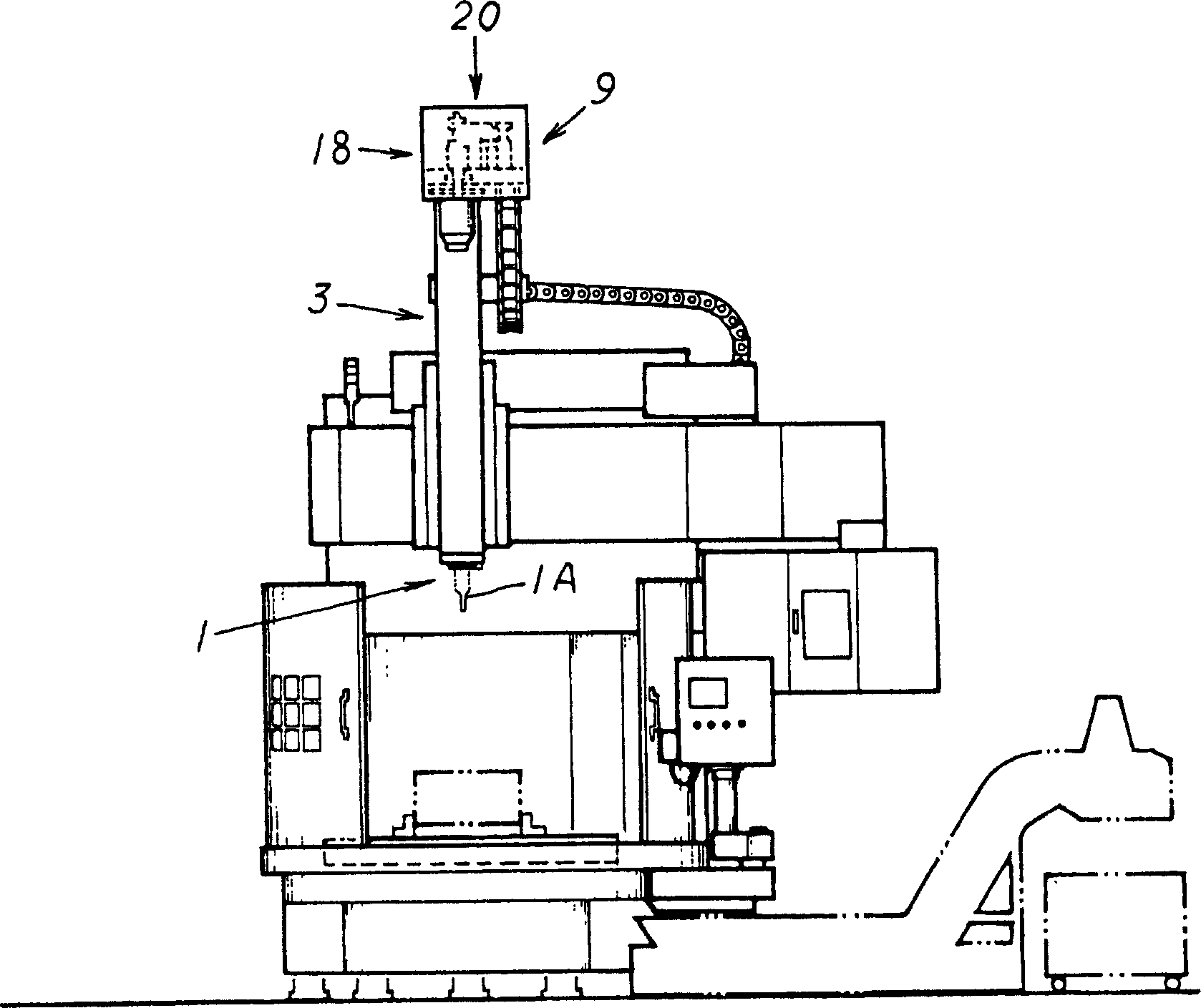

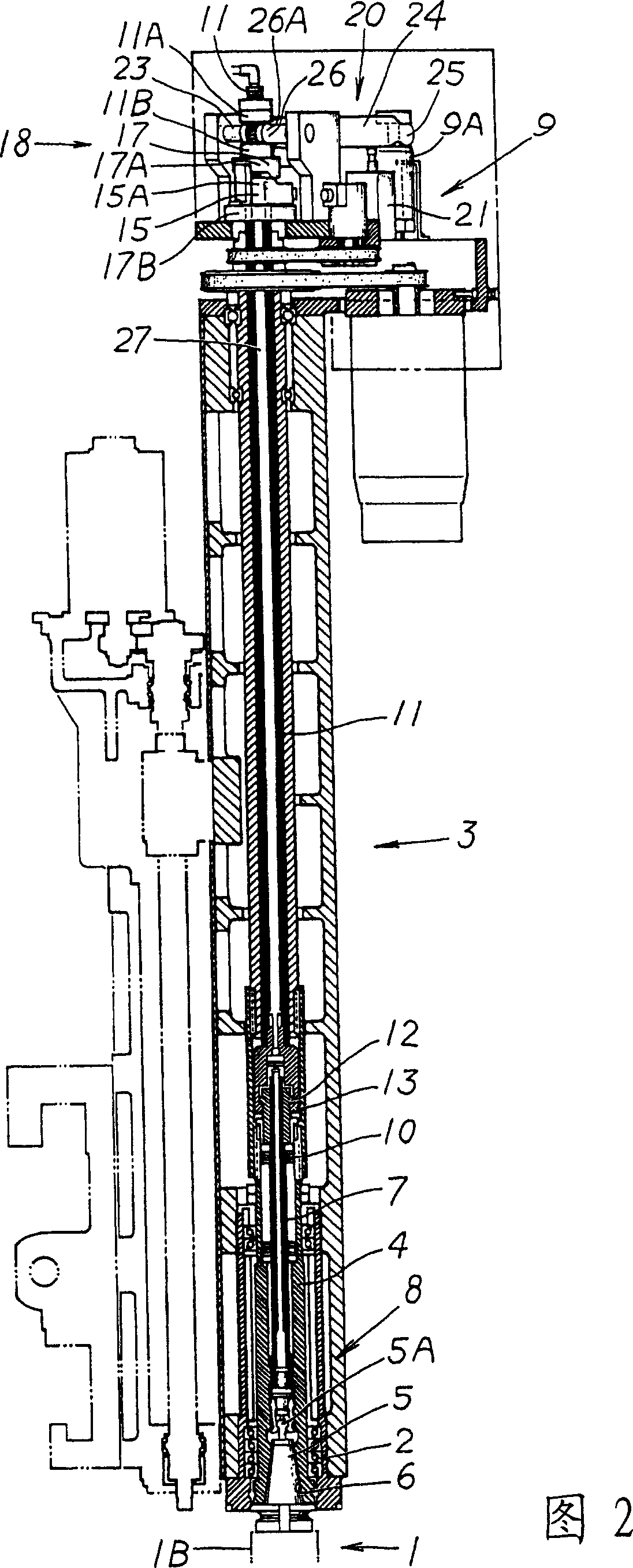

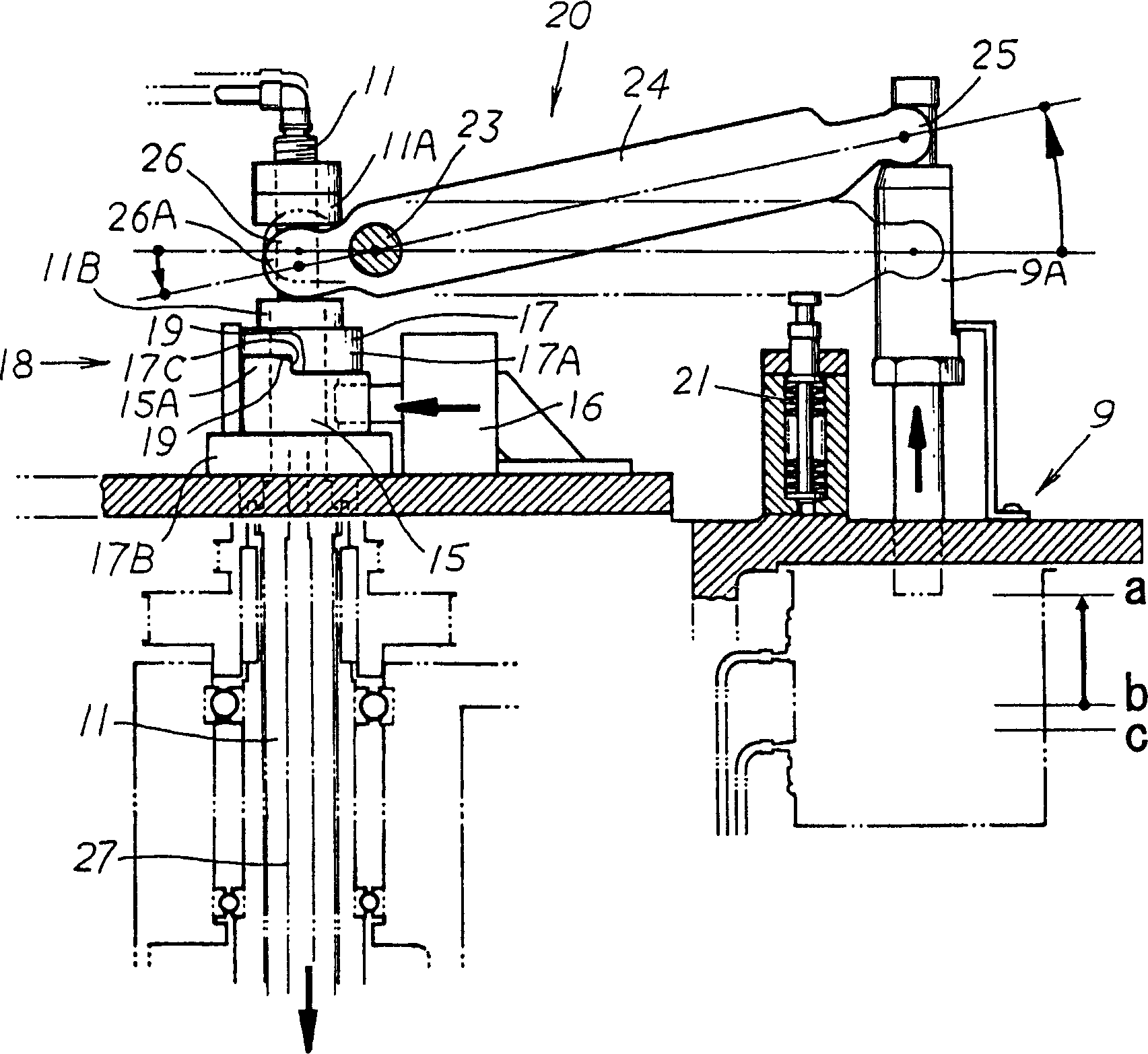

[0041] Preferred embodiments of the present invention (how to carry out the present invention) and functions of the present invention will be briefly described with reference to the drawings.

[0042] When the clamping mechanism 8 performs the clamping action and the pull rod 7 is pulled, the taper shank 5 of the tool 1 is pulled closer and engages with the mounting engaging portion 6 provided on the main shaft 4, so that the tool 1 is clamped and fixed.

[0043] In addition, when the clamping mechanism 8 is released, the pull rod 7 is returned by the push of the advancing and retreating driving part 11 , so that the tool 1 can be attached and detached.

[0044] Specifically, the cylinder device 9 of the clamping mechanism 8, which is the pull rod driving device 9, is changed from the released state a to the first clamped state b, thereby clamping and fixing the rotary tool 1A, but in this case, the pull rod 7 is changed from The release position returned by the forward and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com