Energy dispersion type X-ray diffraction/spectral device

An energy dispersive and X-ray technology, which is applied in the field of energy dispersive X-ray diffraction/spectroscope, can solve the problems of impossible realization and complicated structure of the measuring device, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Referring now to the accompanying drawings, details of the present invention will be explained below.

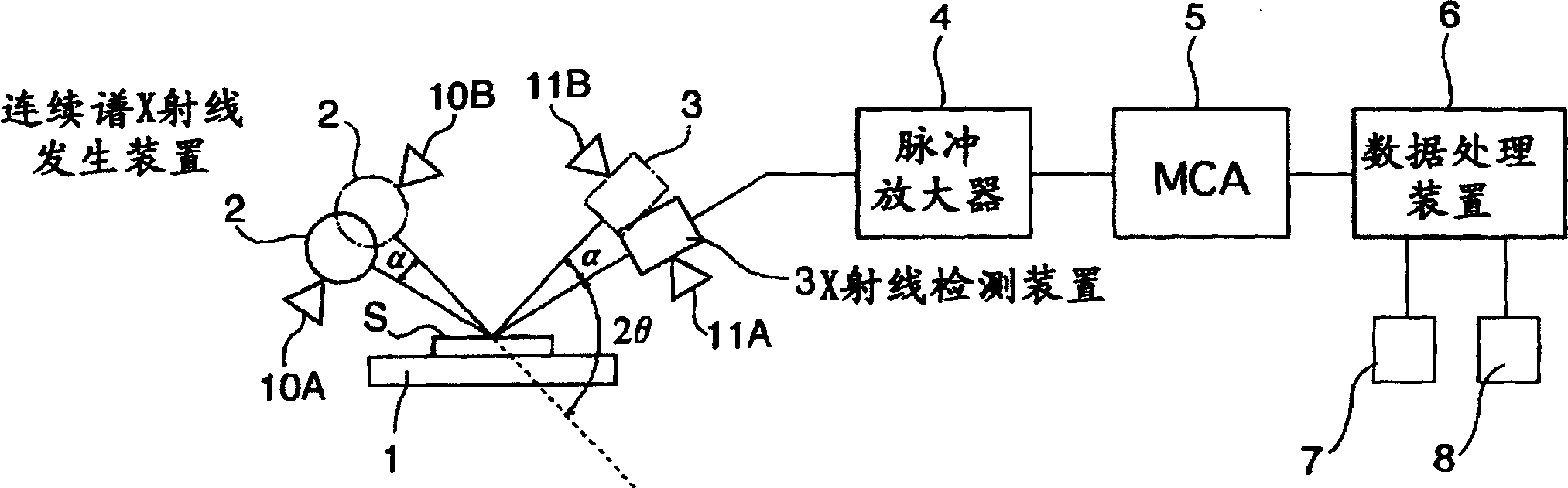

[0029] figure 1 Representing an embodiment of the energy dispersion type X-ray diffraction / spectrometer according to the present invention, wherein a sample base 1 is placed between the continuum X-ray generating device 2 and the X-ray detecting device 3, and a multi-channel analyzer (MCA ) 5 is connected to the output end of the X-ray detection device 3 via the pulse amplifier 4 .

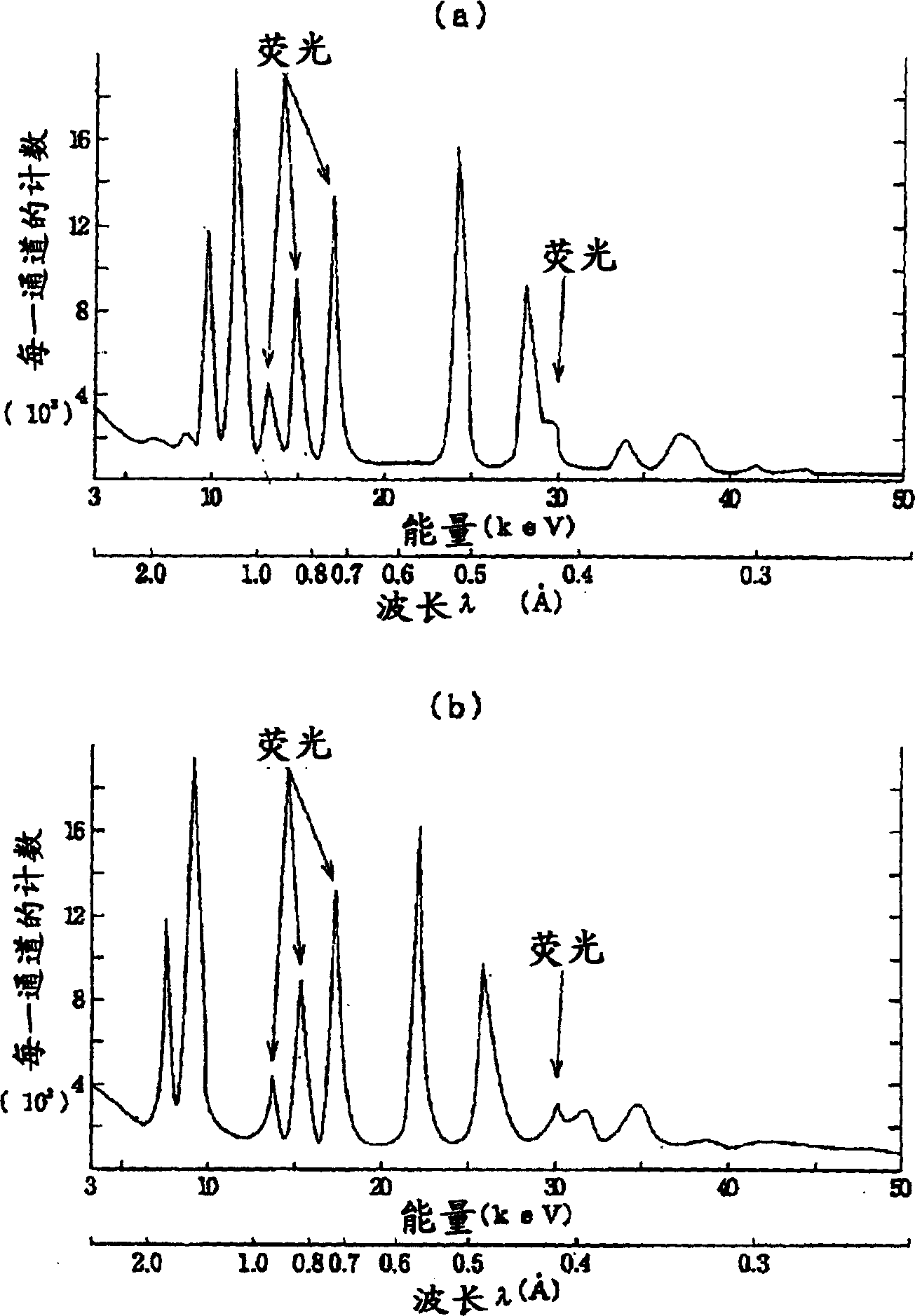

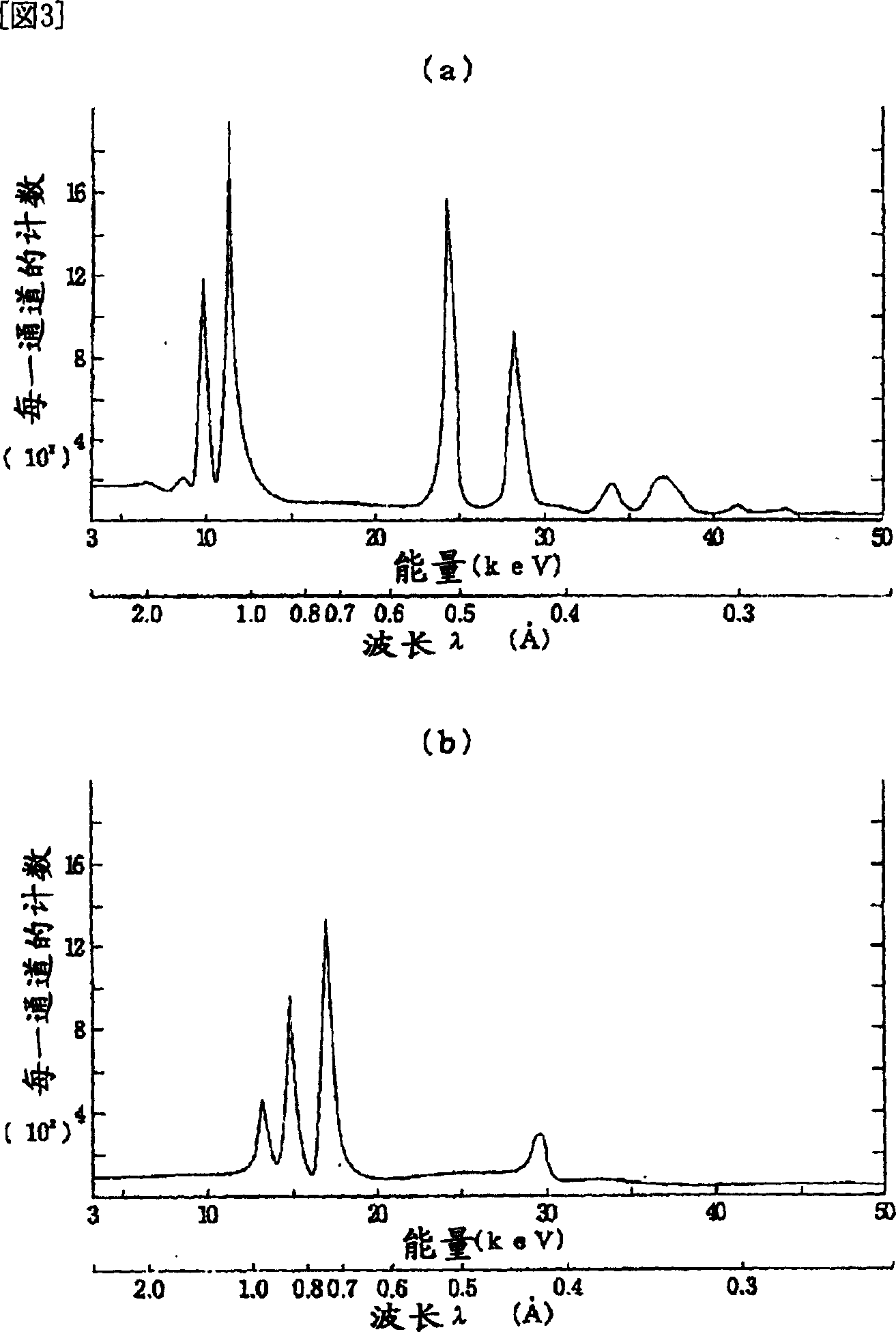

[0030] The sample base 1 is equipped with positioning members 10A, 10B, 11A, and 11B that move between a first position and a second position that determine positions separated by n degrees therebetween so as to shift only the diffracted X-rays, that is, position Relatively shifted by an angle α sufficient to avoid intensity variation of fluorescent X-rays as much as possible, and the positioning members 10A, 10B, 11A, and 11B are configured to be fixed at predetermined positions by a no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com