Column-beam attaching tectosome of architecture and method of attaching the same

A technology for buildings and structures, which is applied in the direction of building construction and construction, and can solve problems such as complex operations, large structures, and inability to transport on roads, so as to save concrete pouring operations and reduce on-site operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

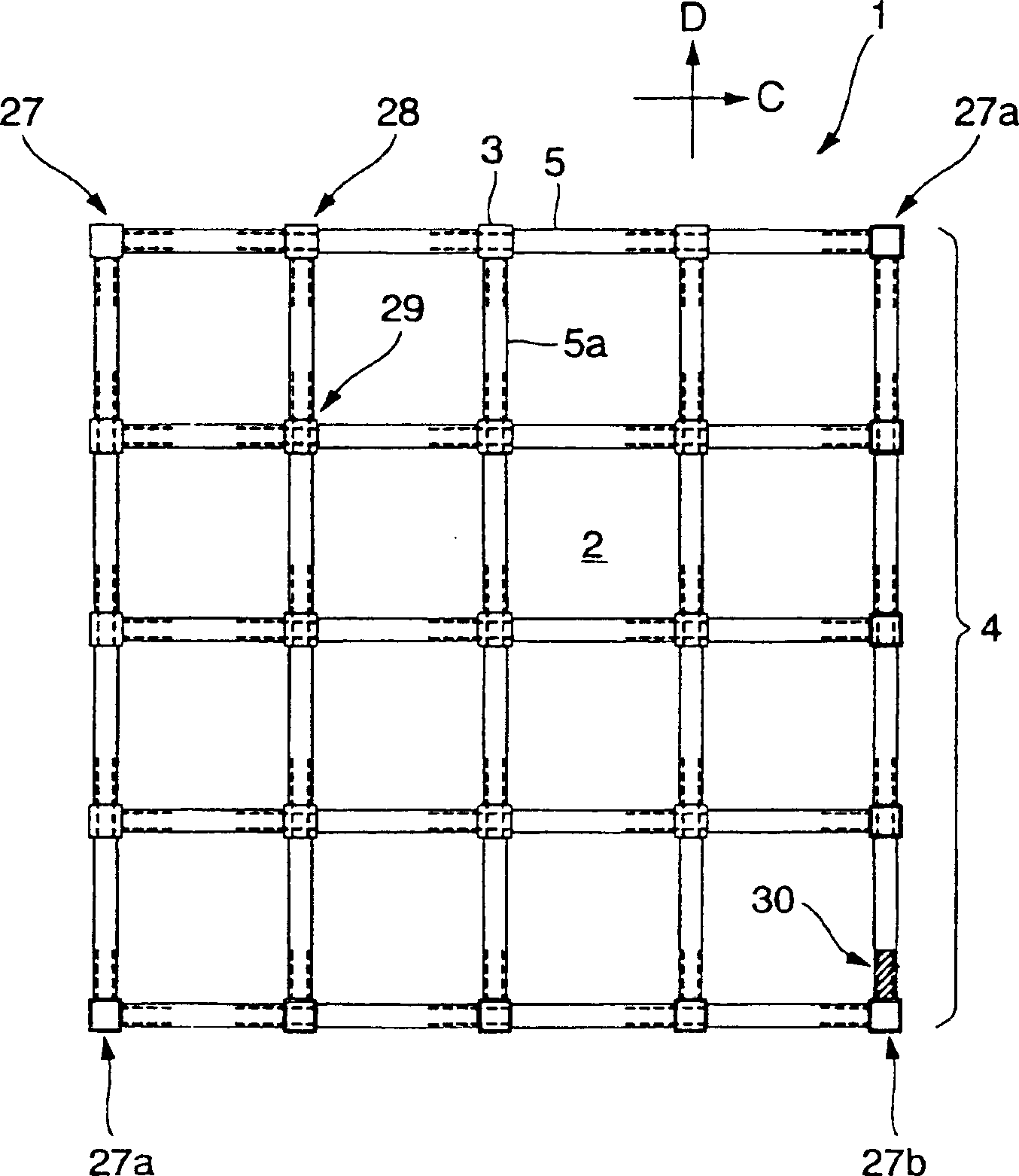

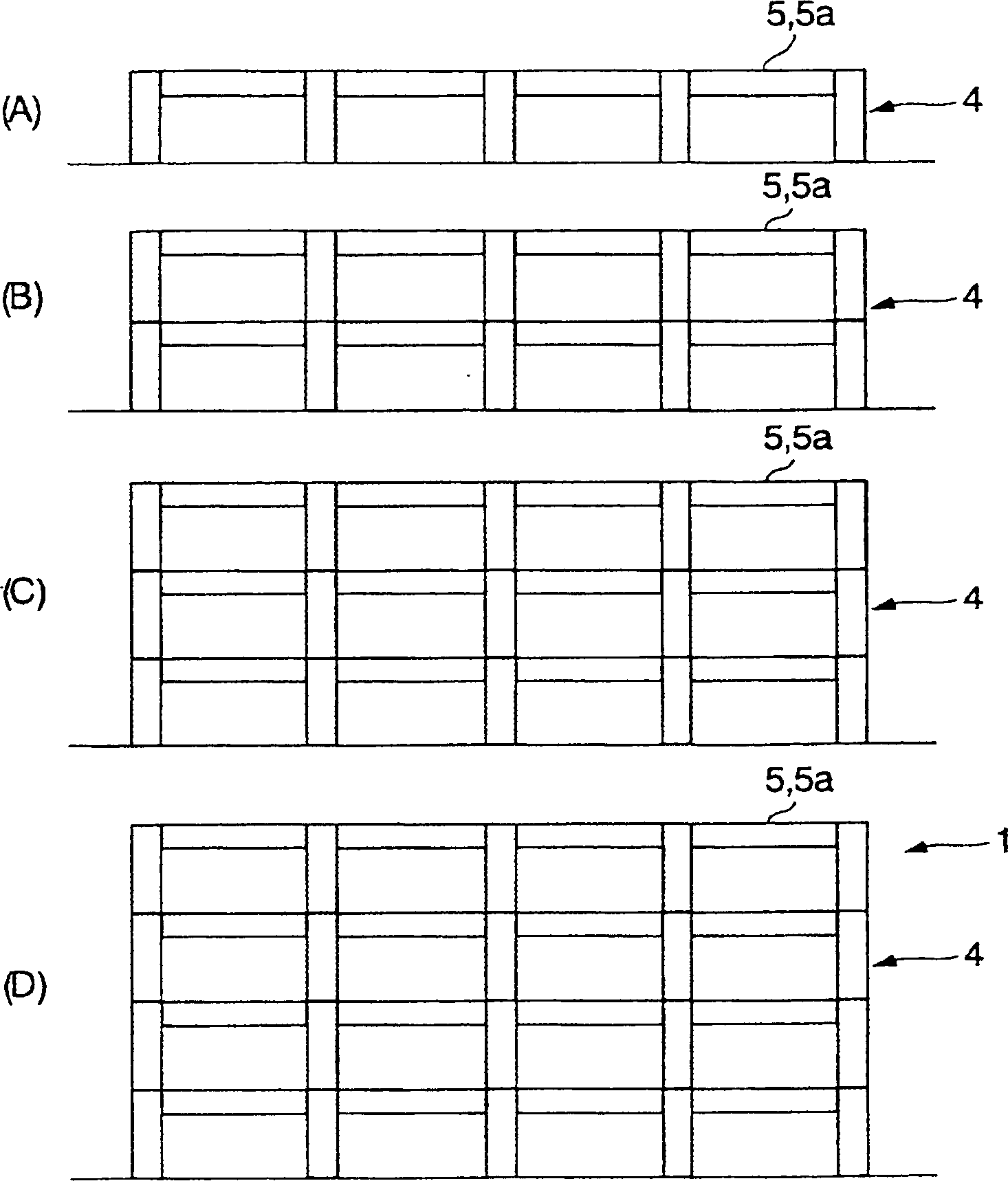

[0037] In the column-beam connection structure of the following embodiment, the column connection part is formed integrally with the precast concrete column, and the several through-holes are formed in the horizontal direction in this column connection part. In addition, a precast concrete beam is installed horizontally on the column connection part, and a plurality of connecting steel bars for the beam protrude from one end surface of the precast concrete beam in the longitudinal direction, and a plurality of beam joints are provided inside the other end surface. part.

[0038] Furthermore, the beam connecting steel bar of the precast concrete beam is passed through the through hole of the column connection part of the precast concrete column, and inserted into the beam joint part of the adjacent precast concrete beam that has been installed, thereby connecting the precast concrete beam through the column connection part. The concrete beams are connected to each other.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com