Method for constructing shear wall cast-in-place area by adopting decoration integrated plates

A technology of one-piece slab and shear wall, which is applied in the processing of walls, building materials, and building components, can solve the problems of failure to solve the problems of joints in the cast-in-place area, many links in the production mode, and many thermal insulation connectors. Achieve the effect of reducing prefabricated production links, improving production efficiency and reducing on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

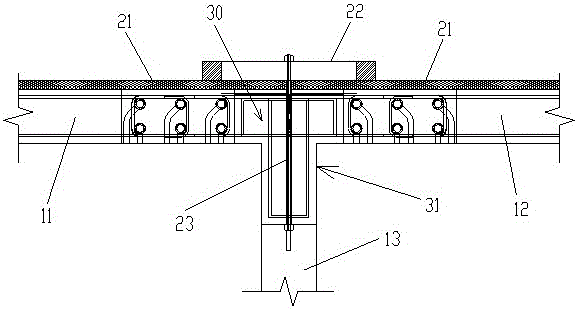

[0026] The technical scheme that the present invention takes is as figure 1 As shown, a method for constructing a shear wall cast-in-place area by using a decorative integrated panel includes the following operations: installing the first, second, and third prefabricated walls 11, 12, and 13; Decorative integrated panels 21 are arranged on the outer wall, the first and second prefabricated walls 11 and 12 are arranged sequentially at intervals, the third prefabricated wall 13 is vertically arranged with the first and second prefabricated walls 11 and 12, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com