Dust and debris extraction apparatus for power tool

A technology for electric tools and suction equipment, applied in metal processing equipment, manufacturing tools, striking tools, etc., can solve the problems of time-consuming, easy to break, and cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

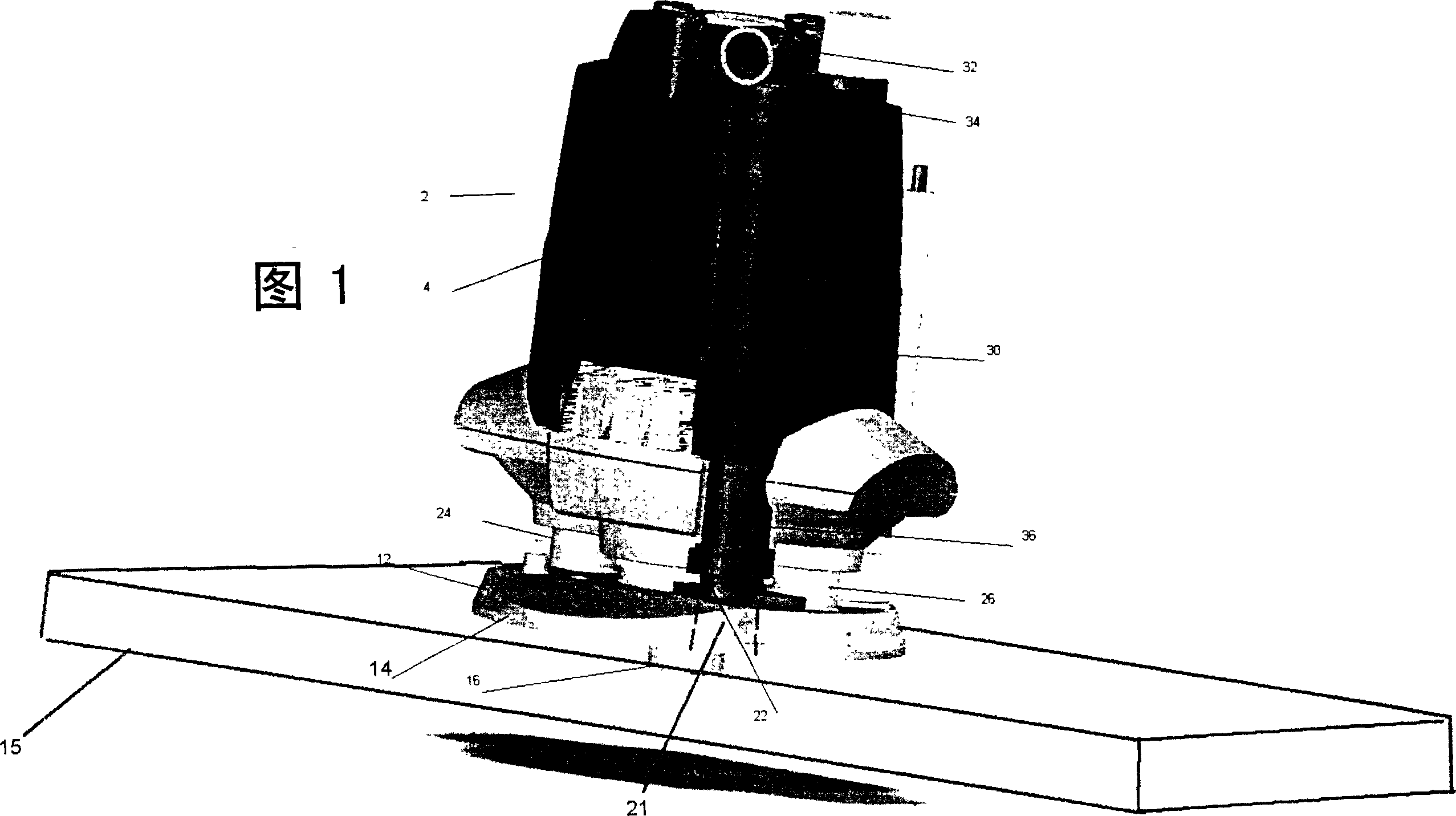

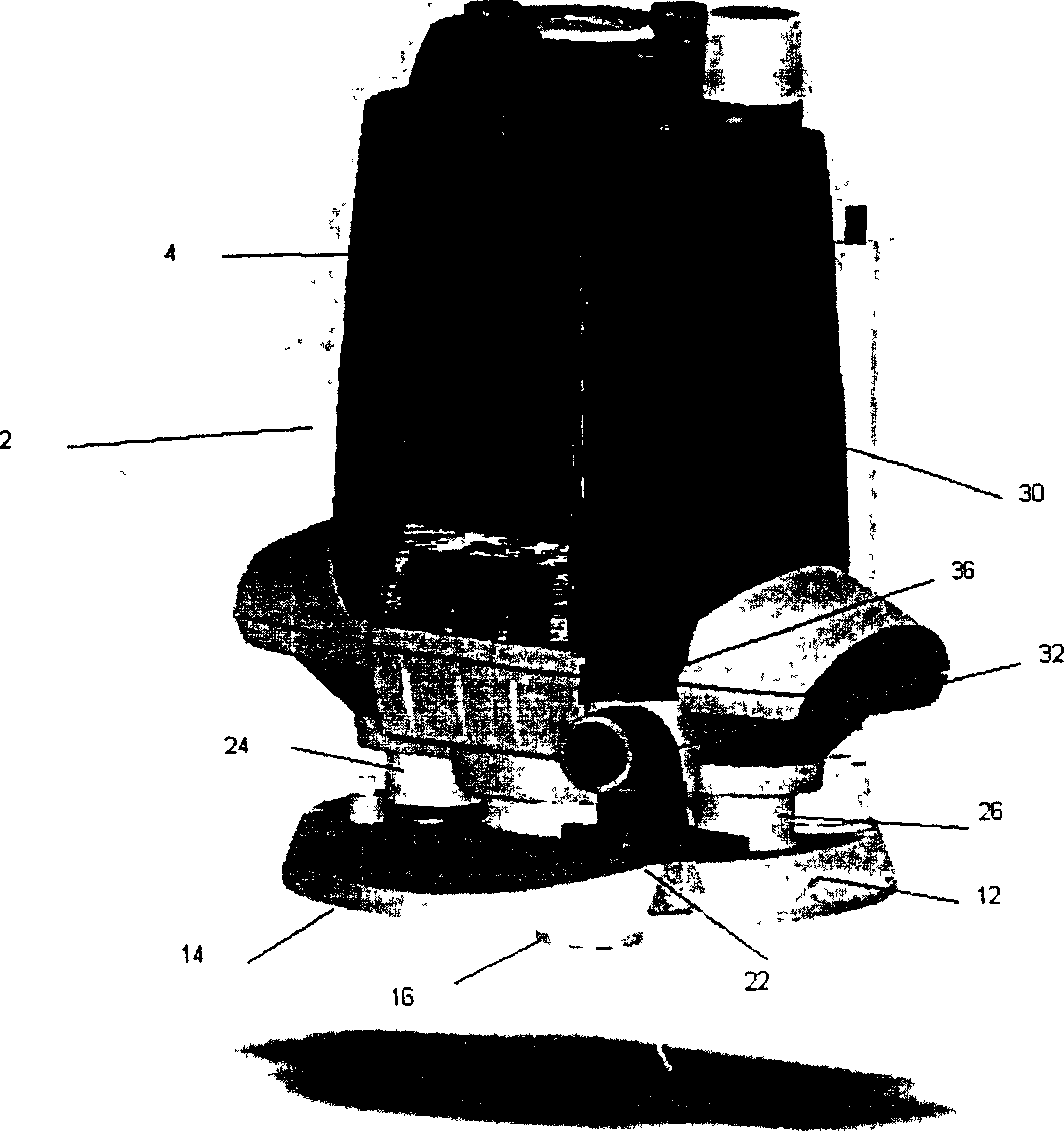

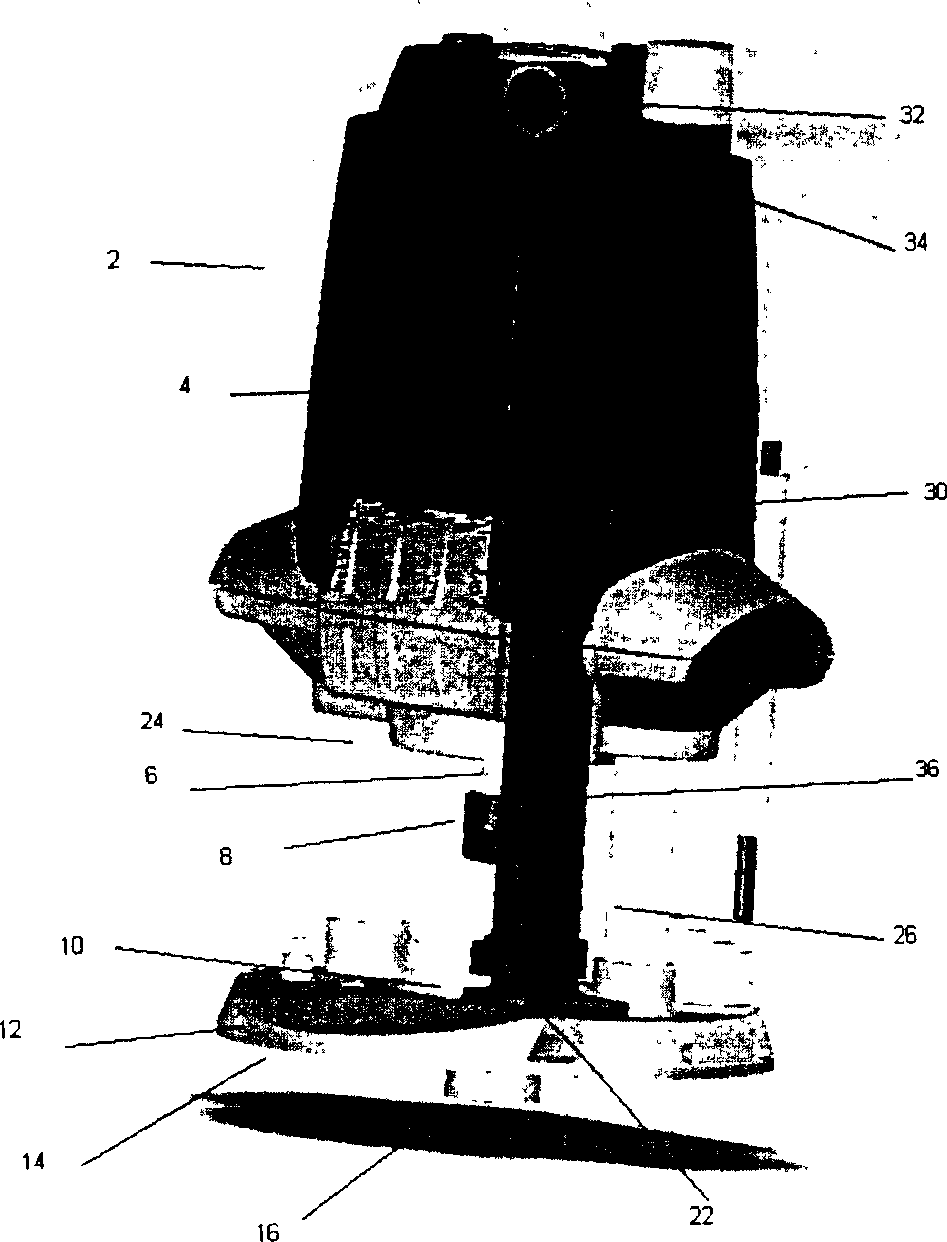

[0027] Referring first to Figures 1-4, there is shown a router 2 according to one embodiment of the present invention. The router 2 includes a body 4 in which a motor (not shown) is accommodated. A motor is connected to rotate a shaft 6 which is selectively connected to any one of a set of router heads 8 . The shaft and router extend through opening 10 in base 12 . In use the underside 14 of the base 12 lies on the plane of a workpiece 15 which is to be subjected to a router operation, which is only shown in FIG. 1 . The underside of the base generally includes a cavity 16 adjacent to the router so that dust and debris generated during operation enters the cavity 16 and then passes through an opening or hole 21 (shown in dotted lines only in FIG. 1 ). The hole), the opening or hole 21 passes through the base from the underside of the base to the upper side of the base and the collar 22. The collar 22 serves as connecting means for connecting the first or second dust and deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com