Mini-size engine

An engine and micro technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of thermal efficiency and output power without ultra-high energy density, and it is difficult to ensure the establishment of mechanical similarity and thermal similarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

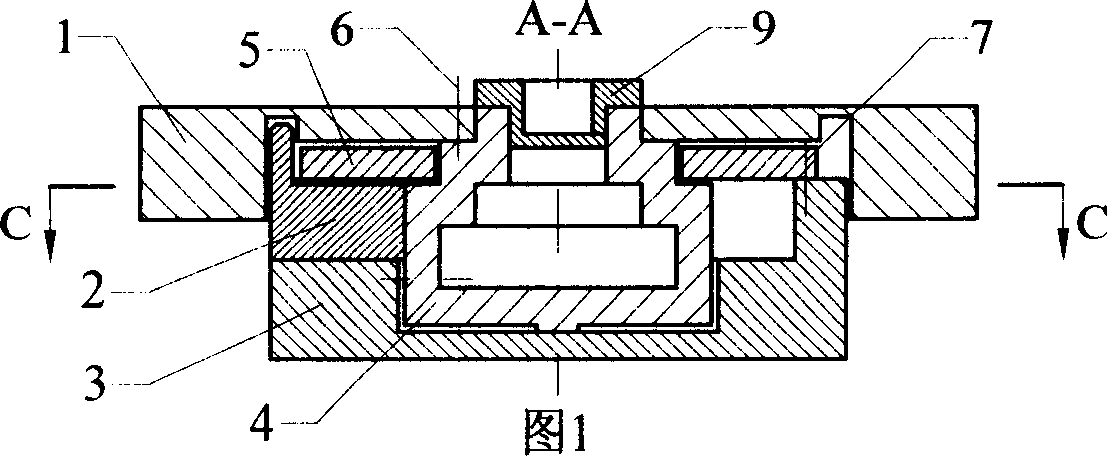

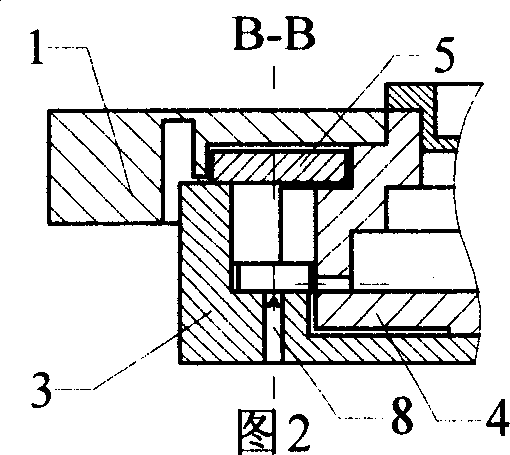

[0030] Below in conjunction with accompanying drawing, micro-engine of the present invention is described in further detail.

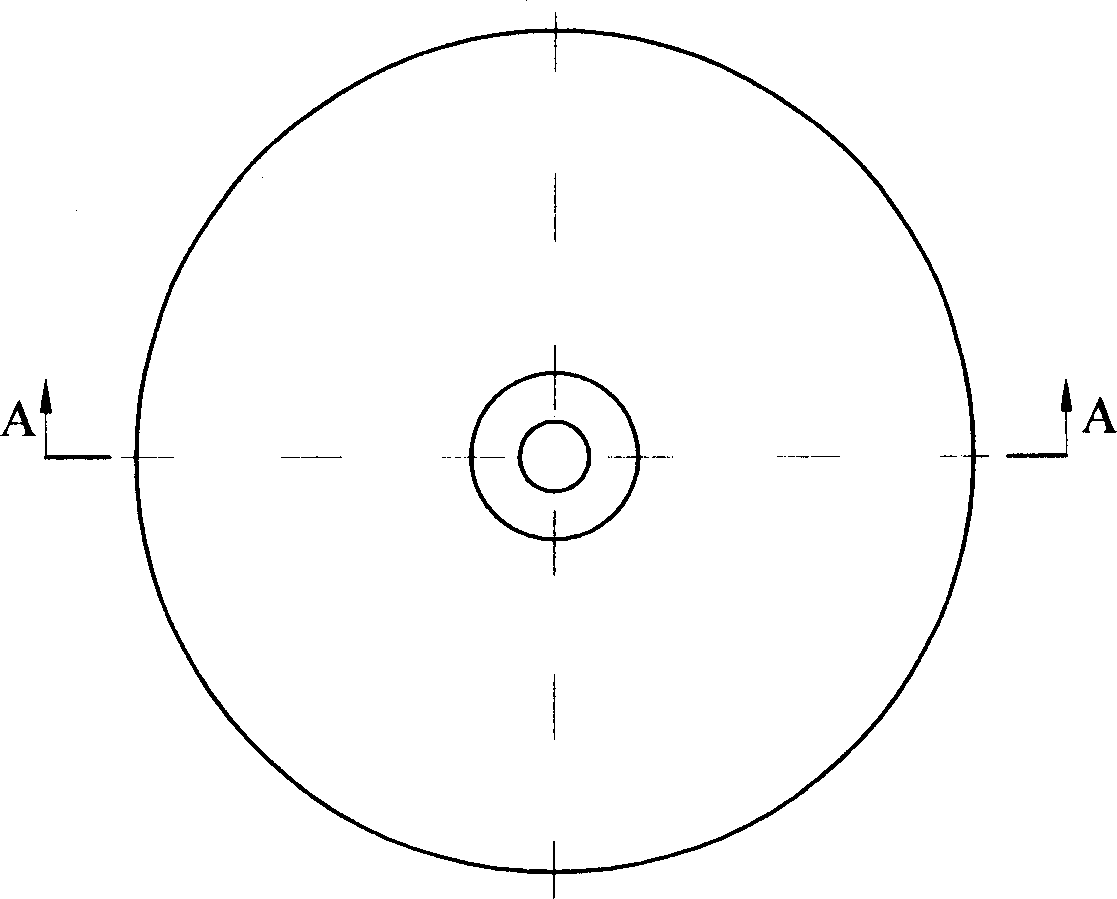

[0031] The micro-engine comprises an inner cam flywheel disc 1, a slide block 2, a cylinder body 3, a piston rotating shaft 4, a cover plate 5, an air transmission mechanism 9 and a probe type spark plug 8. Figure 1~ Figure 4 It shows the positional relationship of each part of the engine when the intake air is combusted. There is a fan-shaped bump type piston on the circumference of the middle part of the side of the piston shaft 4. The center line of the piston is parallel to the horizontal line. The center line of 2 is located on the horizontal center line of the piston shaft and the right side of the slider 2 is movably matched with the outer side of the piston shaft 4; the slider 2 can only slide horizontally in the square slot of the cylinder body 3, and the sliding The upper end of the cylindrical pin on the block 2 is located in the annular g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com