Method for producing compound bioactive peptide utilizing casein enzyme process

A bioactive peptide and casein technology, applied in the direction of fermentation, etc., can solve the problems of complex process and high production cost, and achieve the effect of simple process, mild conditions and strong hydrolysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

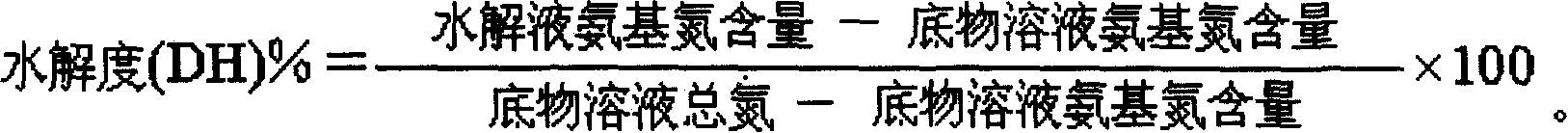

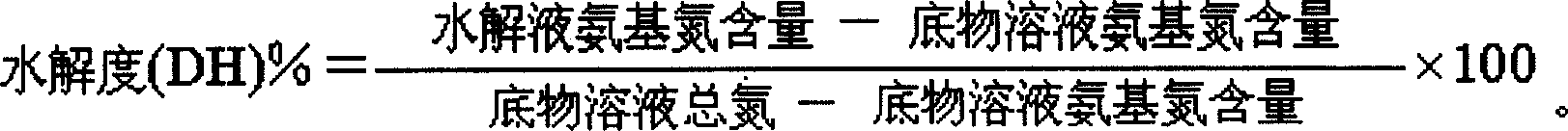

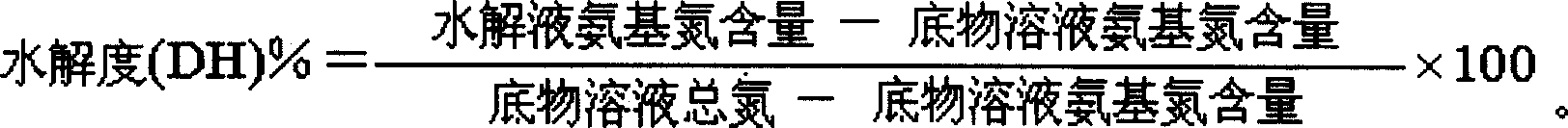

Image

Examples

Embodiment Construction

[0018] (1) Preparation of enzymatic hydrolysis substrate:

[0019] Add 320ml of distilled water to 80g of casein to swell, adjust the pH to 8.0-9.0 with 6mol / L NaOH, heat to 60°C to dissolve the casein, then adjust the pH to 7.2 with 1mol / L HCl, and finally adjust the volume to 1000ml.

[0020] (2) Enzymolysis:

[0021] 0.8 g of trypsin and 1.2 g of dispase were uniformly dissolved in the prepared substrate solution (slowly stirred until uniform while adding). The enzymatic hydrolyzate was reacted in a constant temperature water bath at 55°C for 6 hours (the hydrolyzate was often stirred or stirred automatically 50 times / min during the reaction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com