Method for extracting and purifying secoisolariciresinol diglucoside from flax seed

A technology of secoisolaricus and glucoside, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of limited application space, high cost, and limited scale, and achieve improved safety and easy Recycling and overcoming the effect of small batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

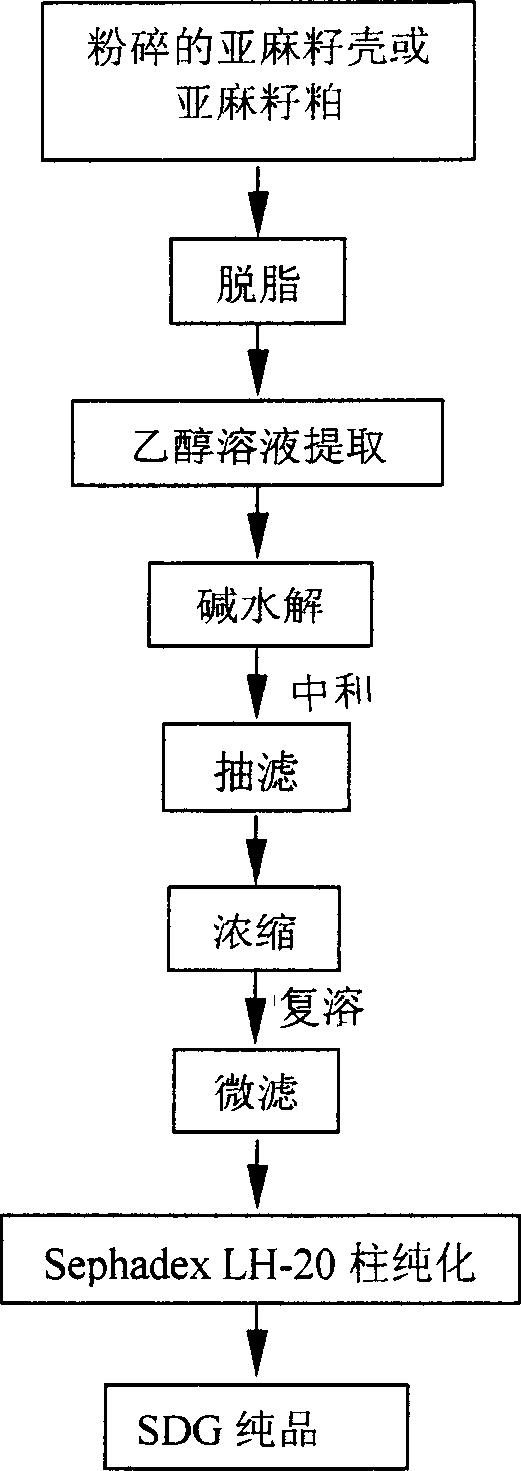

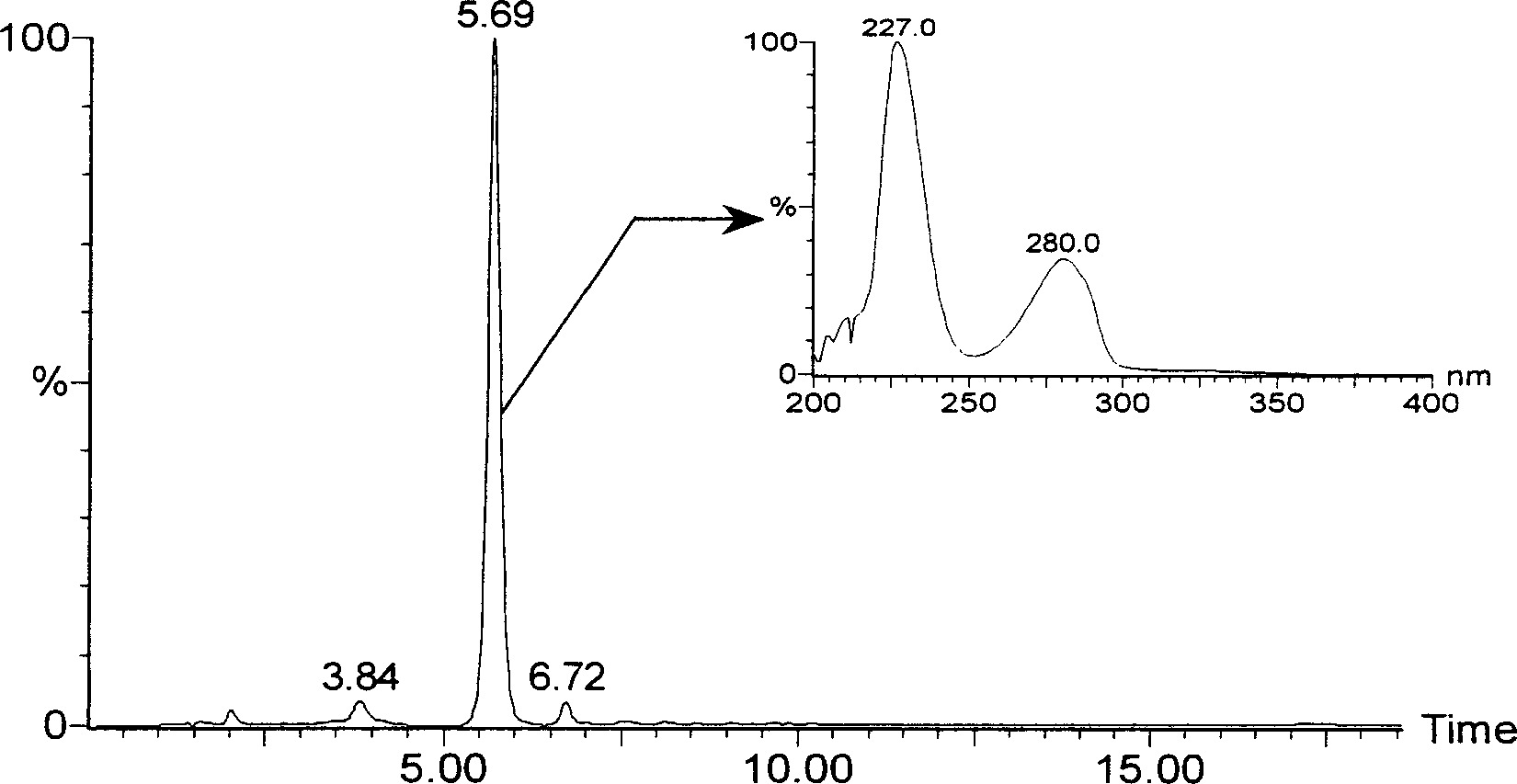

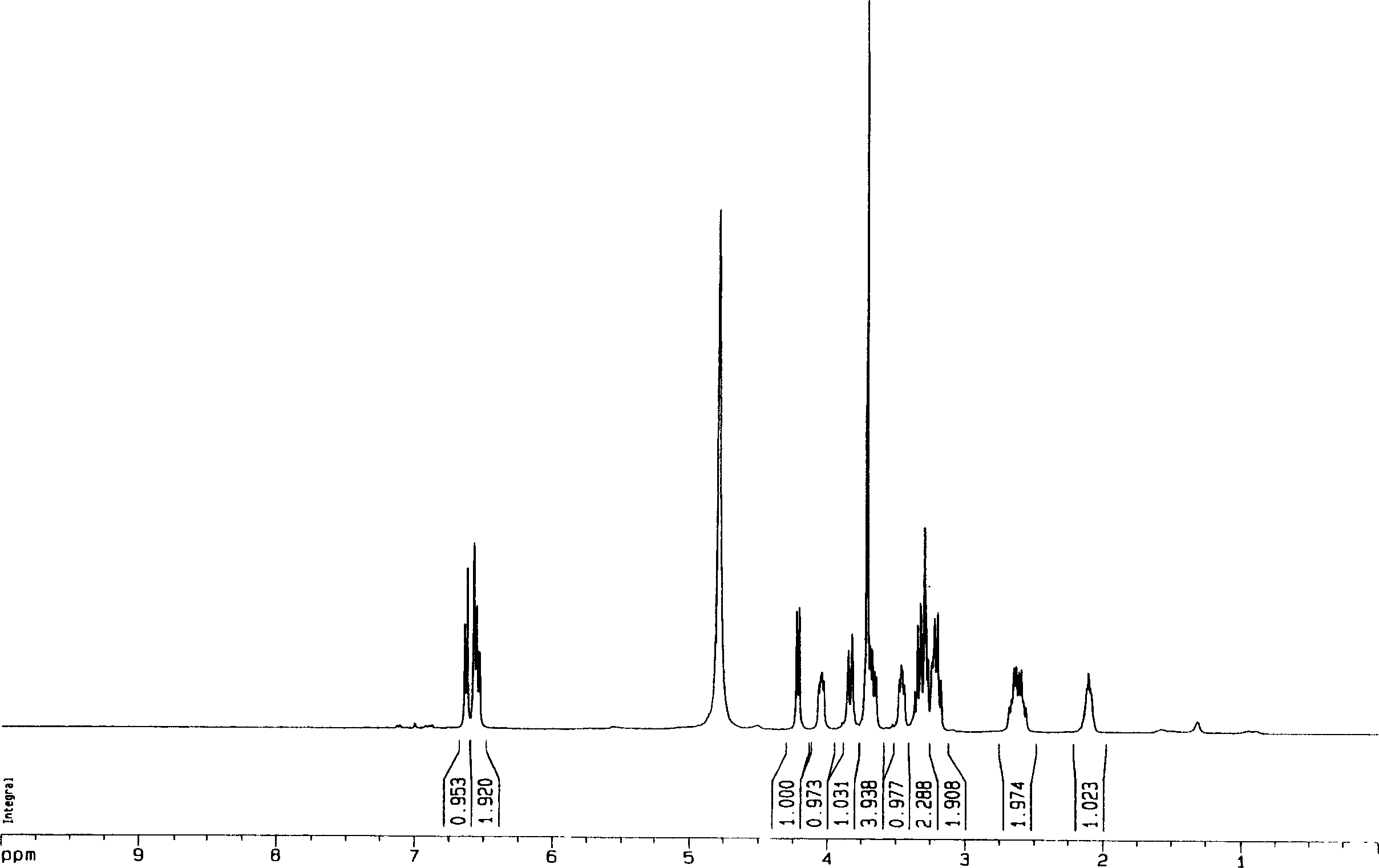

[0026] Weigh 50 g of linseed hulls, crush to 30 mesh, add 500 mL of n-hexane, stir at room temperature for 1 h, and then centrifuge (3000 rpm, 20 min). The residue was degreased again with 500 mL of n-hexane. Add 1000mL of 50% ethanol solution to the defatted flaxseed husk, and stir and extract at 25°C for 4h. Then centrifuge (3000rpm, 20min), add 250mL 50% ethanol solution to the residue, stir and extract for 1h, and then centrifuge. Combine the extracts, add 60mL 6M NaOH solution, stir at 30°C for 2h, then add 6M hydrochloric acid to adjust the pH to 4. Then suction filter and wash the residue with an appropriate amount of ethanol, and combine the filtrates. The filtrate was concentrated under reduced pressure to a thick slurry, reconstituted by adding an appropriate amount of absolute ethanol, and then microfiltered (0.45 μm). Then, the sample was loaded and eluted on a Sephadex LH-20 column with a column length of 100 cm and a column diameter of 1.60 cm. After loading,...

Embodiment 2

[0029] Weigh 50 g of linseed, crush it to 100 mesh, add 1000 mL of No. 6 solvent oil, stir at room temperature for 2 h, and then centrifuge (3000 rpm, 20 min). The residue was degreased again with 250 mL No. 6 solvent oil. Add 500mL of 60% ethanol solution to the defatted linseed husk, and extract with stirring at 60°C for 2h. Then centrifuge (3000rpm, 20min), add 250mL 60% ethanol solution to the residue, stir and extract for 1h, and then centrifuge. Combine the extracts, add 75mL 6M NaOH solution, stir at 30°C for 2h, then add 6M hydrochloric acid to adjust the pH to 6. Then suction filter and wash the residue with an appropriate amount of ethanol, and combine the filtrates. The filtrate was concentrated under reduced pressure to a thick slurry, reconstituted by adding an appropriate amount of absolute ethanol, and then microfiltered (0.45 μm). Then, the sample was loaded and eluted on a Sephadex LH-20 column with a column length of 100 cm and a column diameter of 1.60 cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com