Method and apparatus for preparing high-content polyenoic ethy lester

A polyenoic acid ethyl ester, high-content technology, applied in the direction of carboxylate preparation, organic compound preparation, chemical instruments and methods, etc., can solve the problems such as the inability to produce high-content polyenoic acid ethyl ester products, and achieve structural Simplicity, improved purity, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of high-content ethyl polyenoate provided by the invention is:

[0054] First, the fish oil ethyl ester with a total content of EPA-E and DHA-E of about 27% is pretreated by conventional urea inclusion method to increase the content to 75.5% to form a medium content raw material, in which EPA-E content is 35.3%, DHA -E content was 40.2%.

[0055] Using the above-mentioned ethyl polyenoate with a medium content as a raw material, it is subjected to vacuum film-attached volatilization rectification to obtain a high-content ethyl polyenoate product with a purity of 84%;

[0056] Step 1: Add 100 kg of the medium-content raw material into the vacuum film-attached volatilization kettle of the vacuum film-attached volatilization rectification tower as described below.

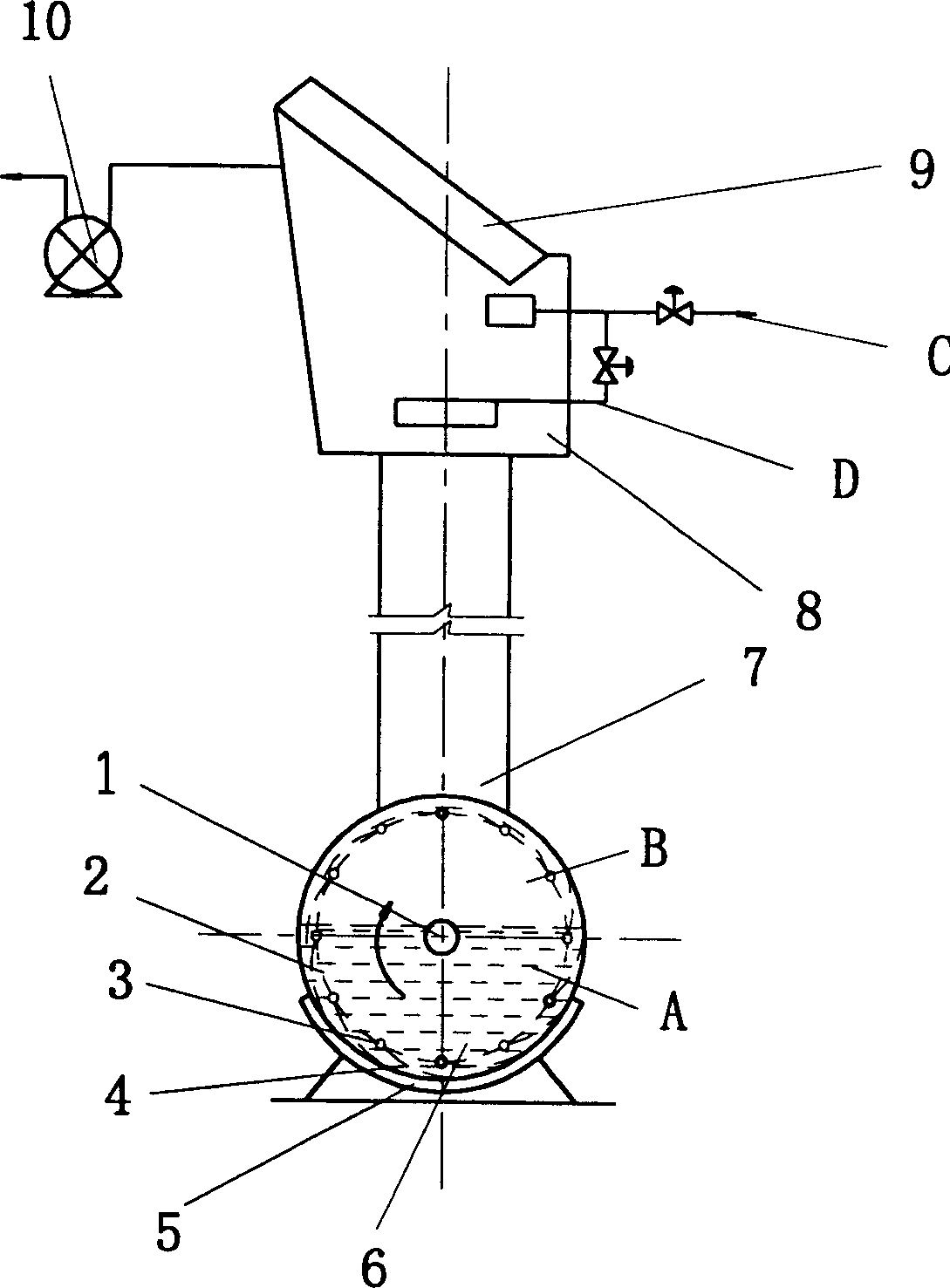

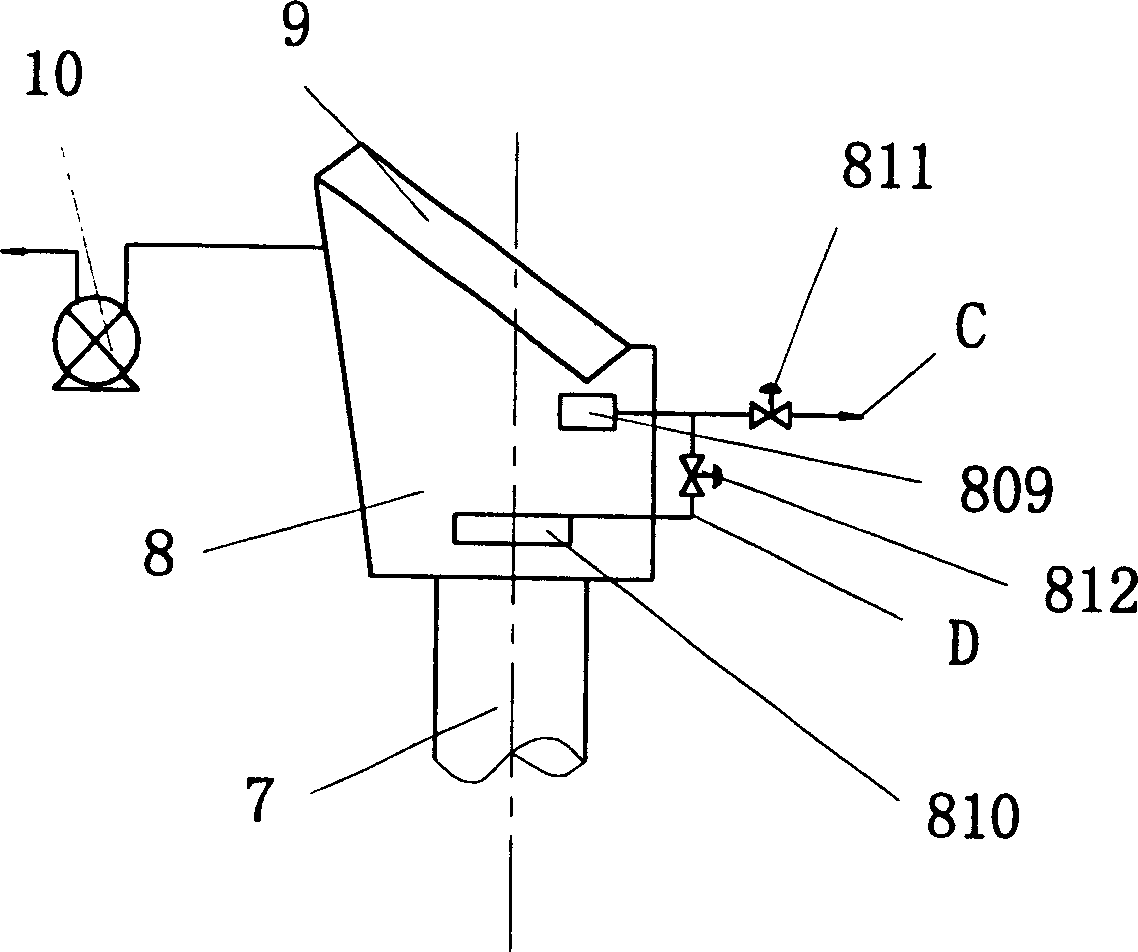

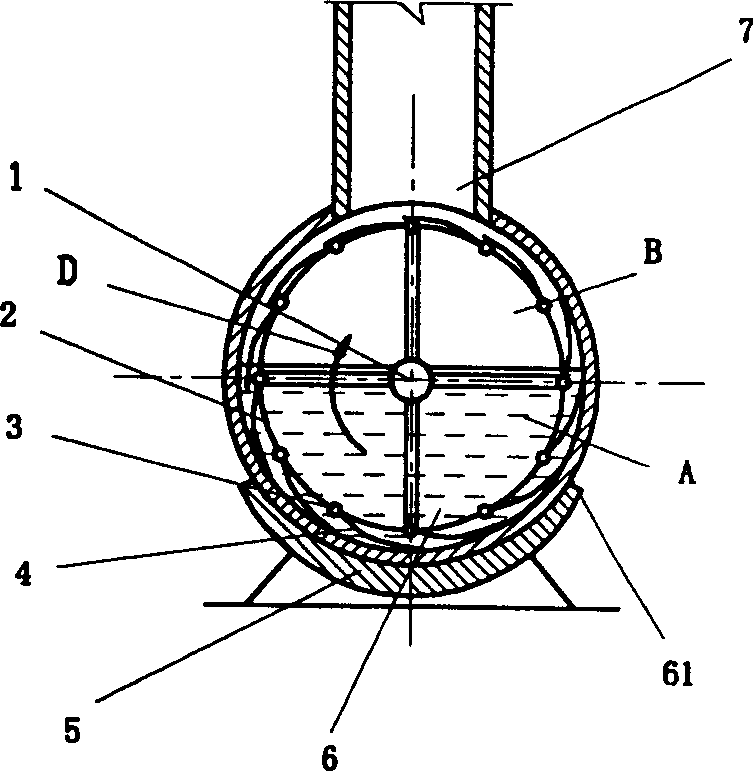

[0057] Such as figure 1 , 2 Shown, this rectifying tower comprises vacuum attached film volatilization kettle 6 at the bottom of the tower, packed rectifying tower tower section 7, tow...

Embodiment 2

[0069] For the fish oil ethyl ester with a total content of EPA-E and DHA-E of about 27%, the conventional urea inclusion method is used to pretreat the content to a medium content of 70.8%, wherein the content of EPA-E is 30.6%, and the content of DHA-E The content is 40.2%.

[0070] Using the polyenoic acid ethyl ester with medium content of EPA-E and DHA-E obtained after pretreatment as raw material, it is subjected to vacuum film-attached volatilization and rectification to obtain high-content EPA-E and DHA-E with a purity of 80.5%. E product;

[0071] Step 1: 100 kilograms of the raw materials are added into the volatilization still of the vacuum distillation tower substantially the same as in Example 1. As shown in Figure 4, the film attaching device at the bottom of sweeping wherein is a roller 4 ', and it is installed on a rotating shaft frame 41 ', and this rotating shaft frame is rotatably installed on the hinged shaft 3 of the annular support 2.

[0072] In step 2...

Embodiment 3

[0076] Use the same raw material as embodiment 1, in the same rectifying tower, carry out the volatilization rectification process with vacuum film attached, the difference is, as shown in Figure 5, sweeps the bottom film attached device is a cylinder 42 ", and it is rotatable The ground is sleeved and fixed on the hinge shaft 3. Use it to replace the arc blades. Under the action of gravity, the upper part of the inner wall of the cylinder is always in contact with the hinge shaft 3. When the cylinder 42 "turns to the bottom of the kettle with the main shaft At this time, the outer side wall of the lower part of the cylinder 42 "contacts the bottom of the kettle to sweep the bottom. When the cylinder 42" rotates the upper part of the kettle, the outer side wall of the upper part is away from the inner wall of the kettle.

[0077] The temperature at the bottom of the tower is 180-190°C, the temperature at the top of the tower is 110-120°C, the degree of vacuum is 10-12Pa, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com