Ore melting and moltenmass modulating method and equipment for continuous basalt fiber production

A technology of basalt fiber and modulation method, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high energy consumption, insufficient economy, and inability to penetrate high-temperature impurities of quartz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

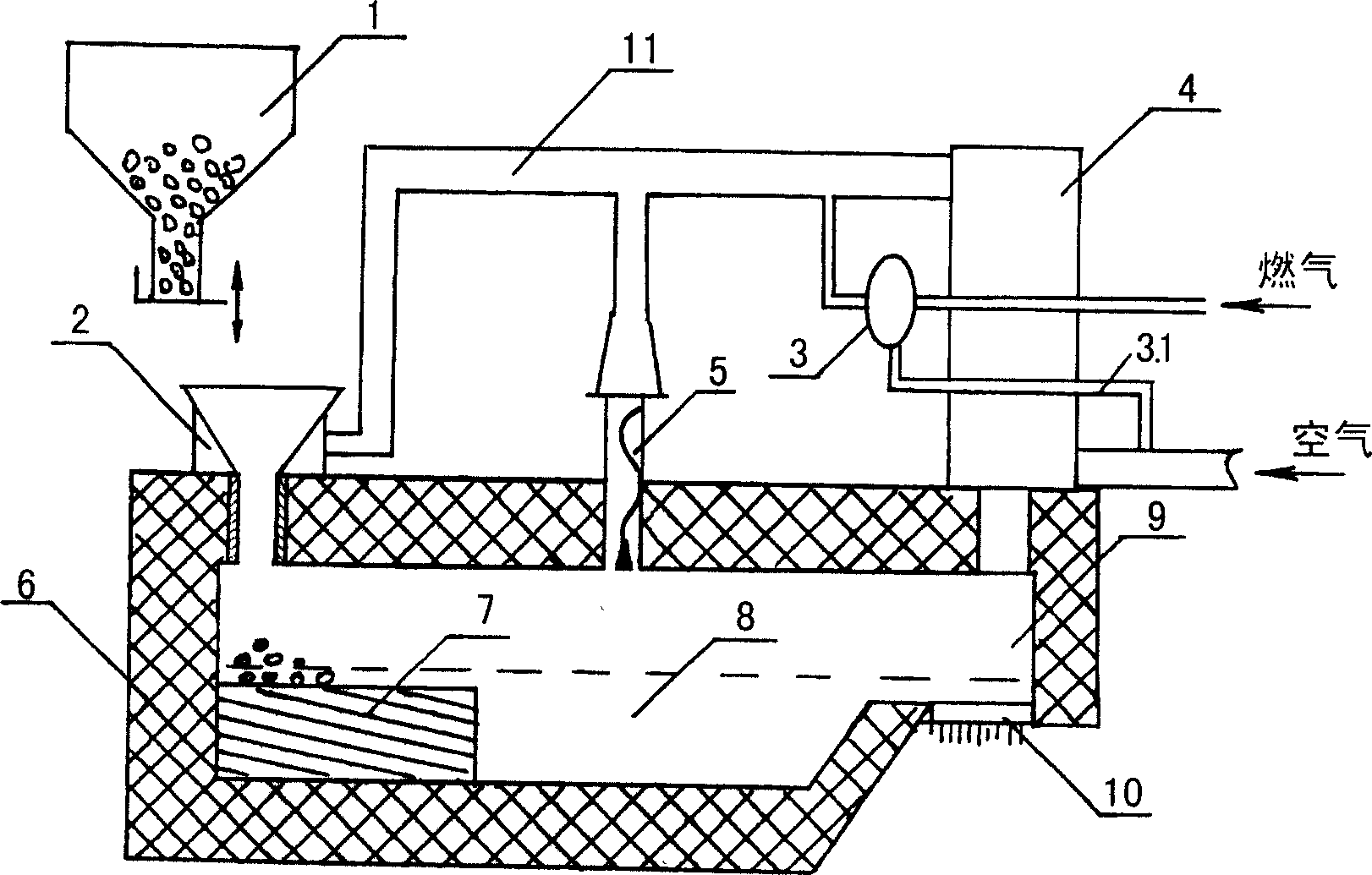

[0057] Embodiment: Utilize the equipment shown in accompanying drawing to produce the molten body required for continuous basalt fiber

[0058] The raw material of basalt ore is basalt ore containing 2-3% quartz, and the chemical composition (by weight) of basalt is: SiO 2 51%, Al 2 o 313%, Fe 2 o 3 ·FeO11%, TiO 2 2.5%, CaO10%, MgO·MnO5.2%, K 2 O3.5%, Na 2 O3.8%.

[0059] The production device adopts a 200-hole drawing bushing, and its production capacity for continuous basalt fibers with a fiber diameter of 6-13 microns is 8kg / h-12kg / h.

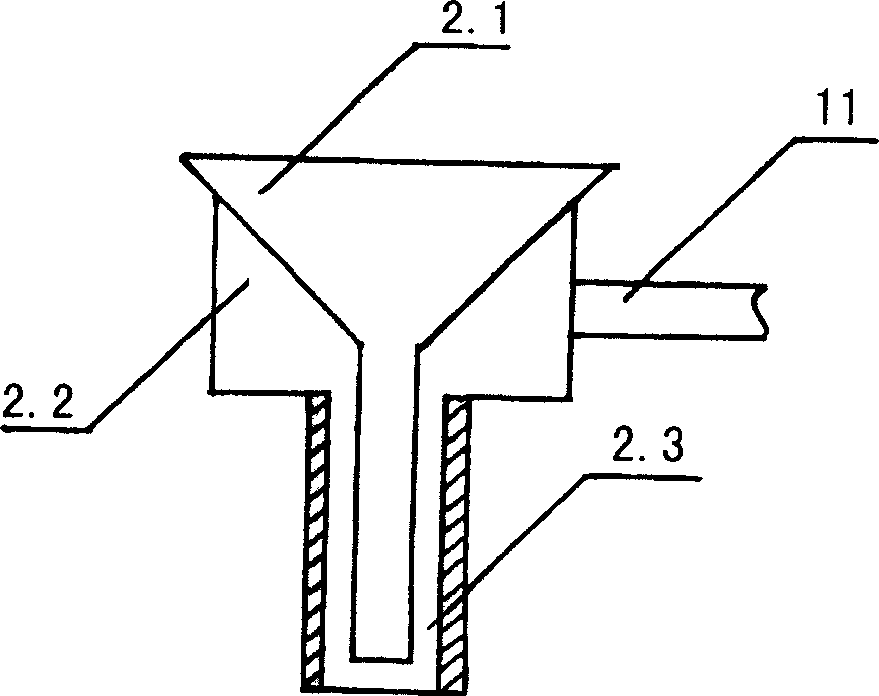

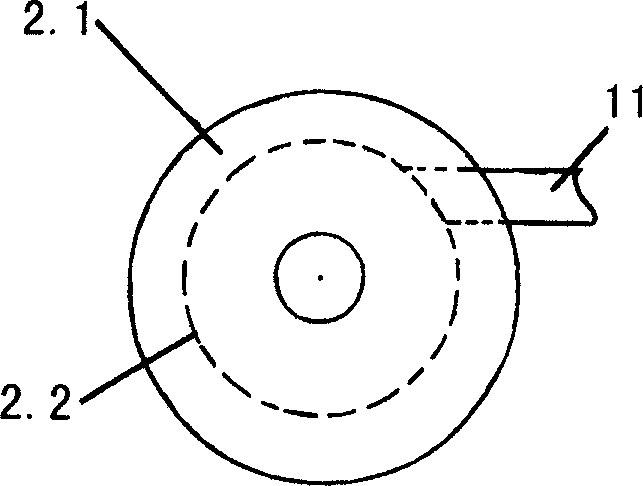

[0060] The basalt ore fragments with a screen size of 3-25mm are sent to the melting working platform in the furnace body of the ore melting furnace through the burner-feeder on the roof of the melting furnace in batches, and the feeding amount is controlled by the feeder meter. The dosing parameters were set to add 80-90 grams of ore over a period of 80 seconds. In the melting zone, a melting working platform with an area of 400×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com