Method for regenerating a particle trap

A particle trap and mixer technology, applied in machine/engine, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as inability to achieve temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

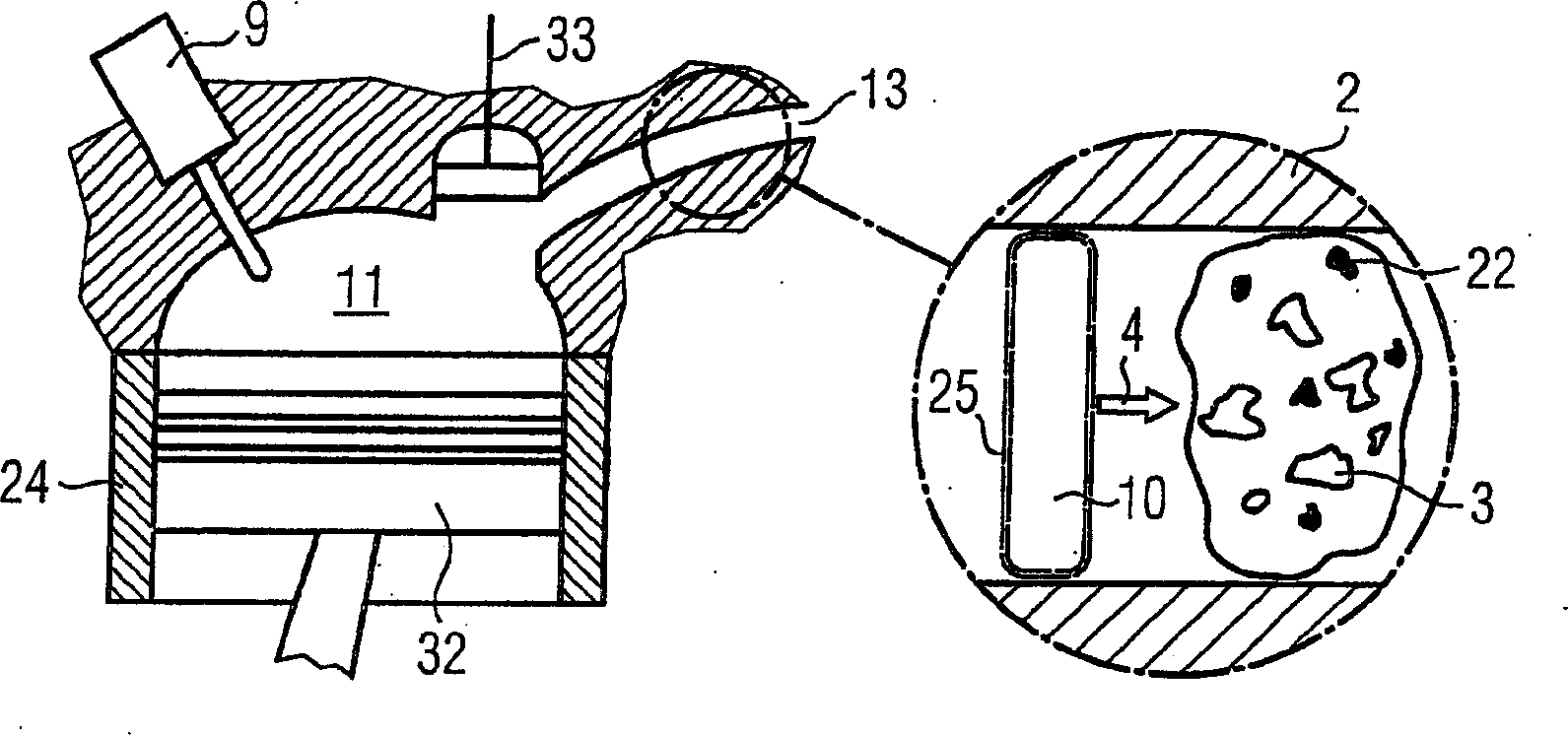

[0045] FIG. 1 schematically shows a perspective view of an exhaust system 1 for cleaning a gas flow 2 of pollutants 3 . In flow direction 4 of gas flow 2 , exhaust system 1 comprises at least a first catalytic converter 5 , a mixer 6 , a second catalytic converter 7 and a particle trap 8 . Furthermore, means are provided for supplying the reducing agent, which are arranged only upstream of the mixer 6 . Here in an internal combustion engine 12 , preferably a diesel engine for a passenger vehicle, fuel 10 is injected into the combustion chamber 11 of the individual cylinders 24 . The fuel 10 is combusted with highly compressed intake air and is then exhausted through exhaust duct 26 into the surrounding environment.

[0046] In the immediate vicinity of the internal combustion engine 12 , in particular at a distance of less than 70 cm, a plurality of first catalytic converters 5 are arranged, one of each first catalytic converter 5 being integrated in a tube of the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com