Electrohydraulic unloading valve with both hydraulic control mode and electrohydraulic control mode

A working mode, electro-hydraulic control technology, applied in earth-moving drilling, fluid pressure actuating device, mining equipment, etc., to achieve the effect of compact structure, simple operation and reasonable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

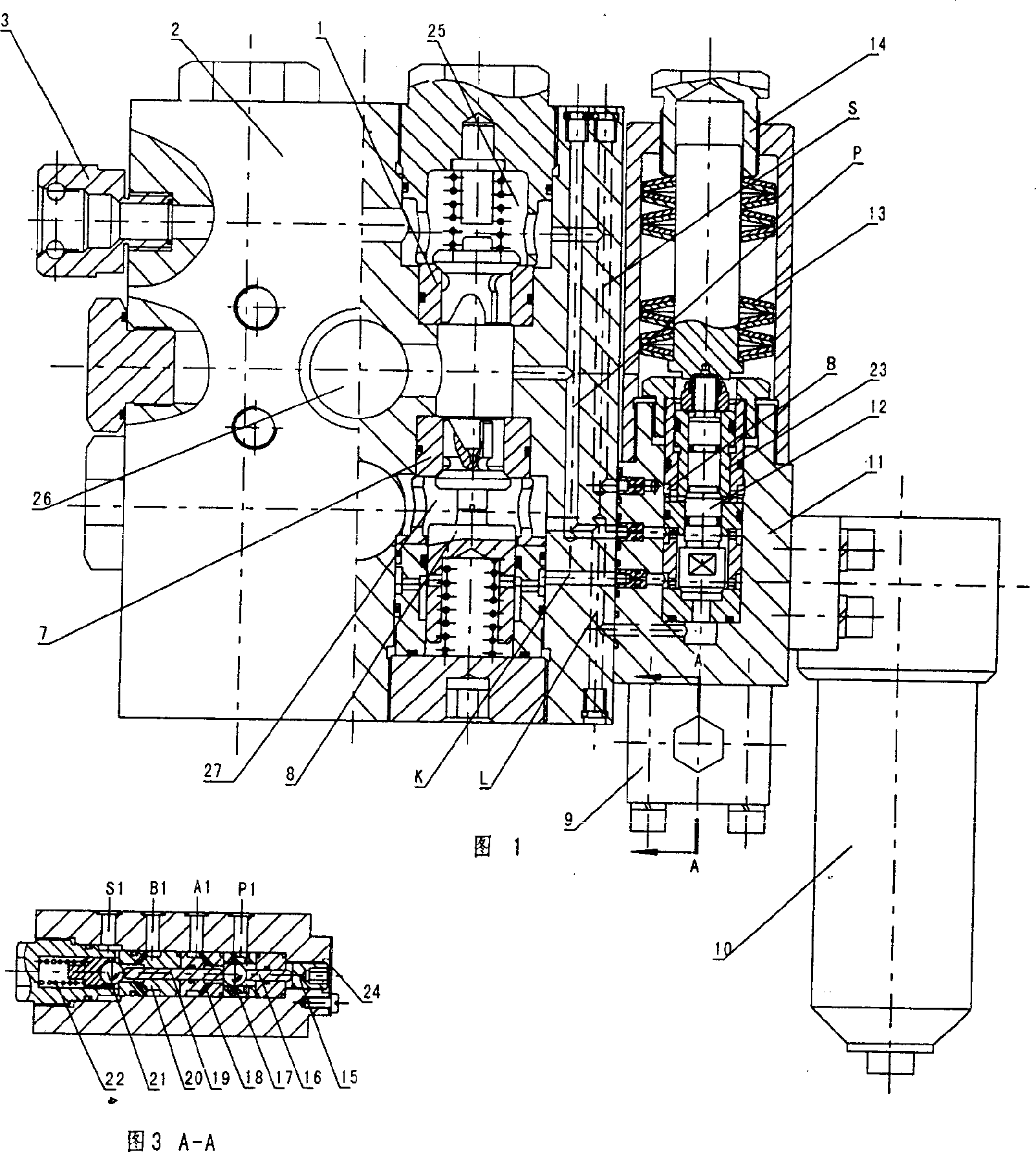

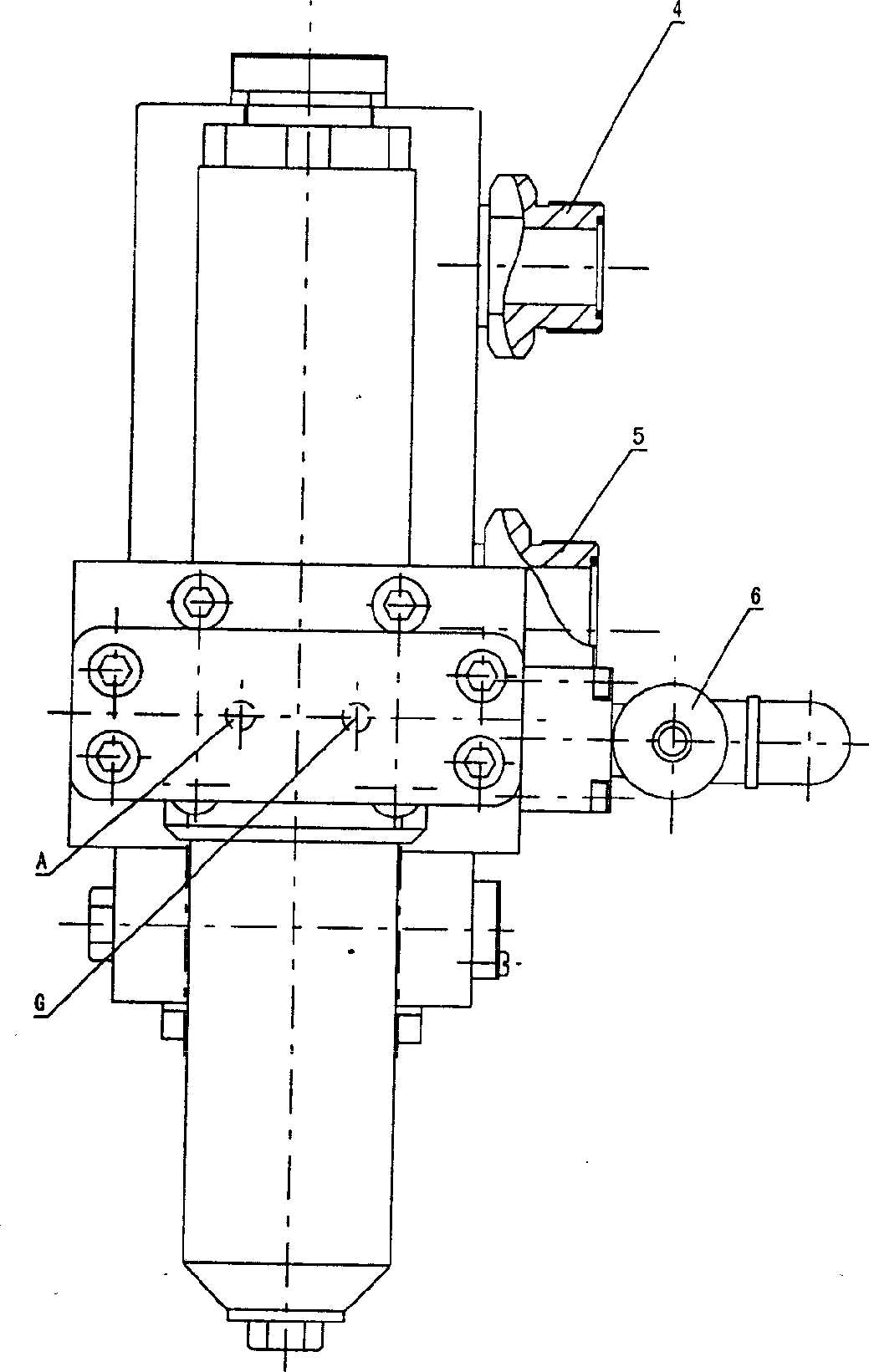

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0012] The invention has an electro-hydraulic unloading valve with two working modes of hydraulic control and electro-hydraulic control. It is mainly composed of a main valve body 2, a pilot valve 11 and a filter 10. Two sets of one-way valve groups are installed side by side in the main valve body 2. 1. The main valve group 7 and the thrust piston 8 are provided with a liquid inlet 26 connected with the liquid path of each valve group. The accumulator joint 3 is installed at the end of the main valve body 2 and communicated with the high-pressure liquid outlet chamber 25. A high-pressure liquid outlet joint 4 is installed above the main valve body 2, and an unloading liquid return joint 5 is installed below the main valve body 2; On the end face, the pilot spool 12 and the copper piston sleeve 23 are installed inside the pilot valve body 1 , and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com