Method for preparing silicic acid-calcium fertilizer and its special furnace

A technology of silicic acid and fertilizer, applied in the direction of calcium fertilizer, inorganic fertilizer, application, etc., can solve the problems of complex production process and high cost of silicon fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: the method for preparing this monocalcium silicate fertilizer, 1. use the fine white sand and lime water slurry that the glass factory cleans the raw material discharge to mix with 2: 1 by weight percentage, after manual or machine stirring, be processed into fine white sand ② put the fine white sand, calcium carbonate stones and coke into the high-temperature furnace for smelting according to the weight percentage of 2:1:1. , the smelting temperature is above 3000°C, and the monocalcium silicate solution can be obtained continuously; ③ After the monocalcium silicate solution is cooled, it is crushed into granules, and the monocalcium silicate fertilizer can be obtained.

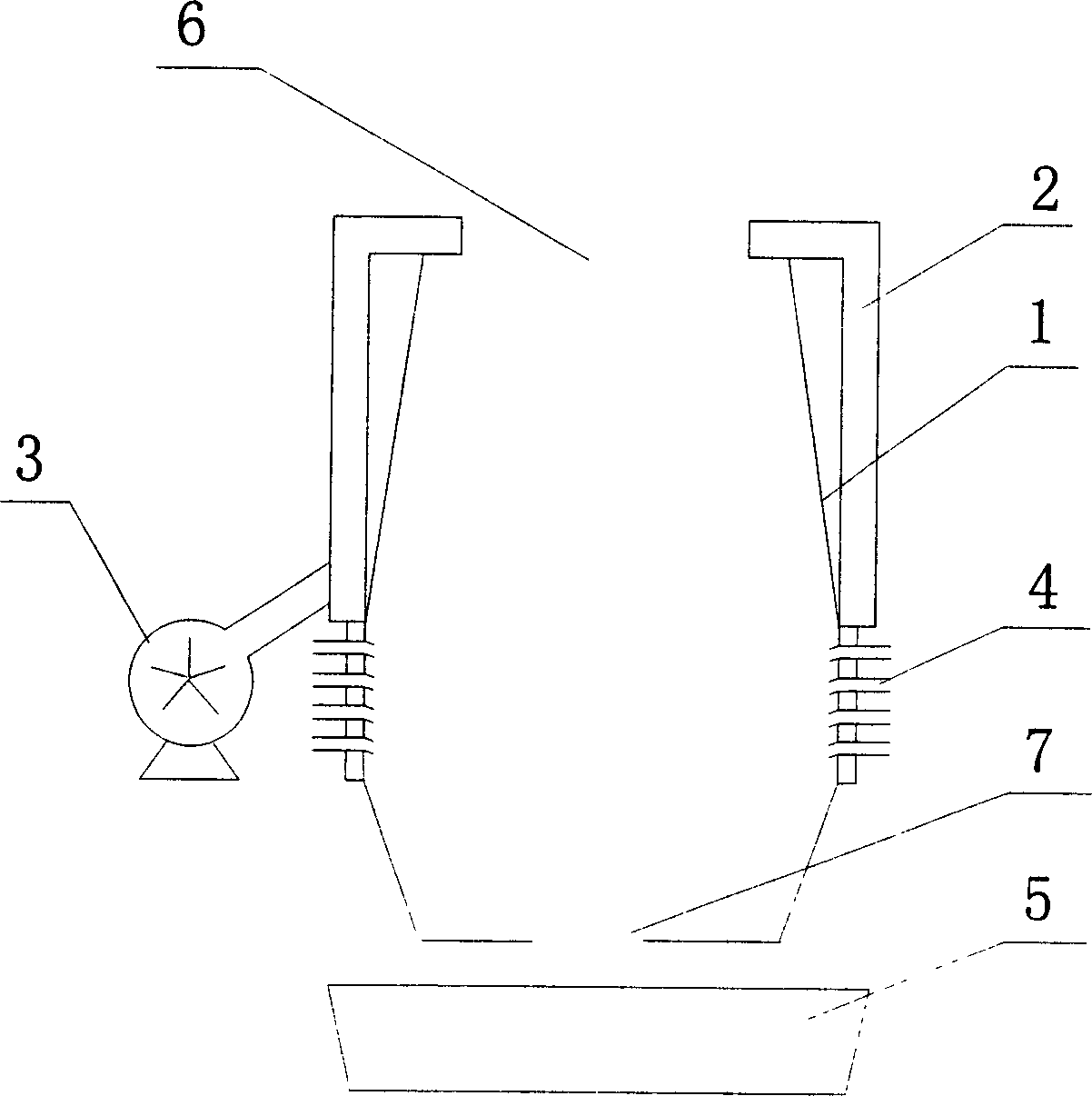

[0010] The special melting furnace used in this invention is made up of furnace body 1, hot air belt 2, air blower 3, observation hole 4, cooling pool 5, and furnace body 1 has upper feed port 6 and lower outlet outlet 7, below the lower outlet outlet 7 is Cooling pond 5, observation hol...

Embodiment 2

[0012] Embodiment 2: the method for preparing this monocalcium silicate fertilizer, 1. use the fine white sand and lime water slurry that the glass factory cleans the raw material discharge to mix with 2: 1 by weight percentage, after manual or machine stirring, be processed into fine white sand ②Put fine white sand, calcium carbonate stones, and coke into the high-temperature furnace for smelting according to the weight percentage of 2:1:1. The total weight of each time is 80 kg. , the smelting temperature is above 3000°C, and the monocalcium silicate solution can be obtained continuously; ③ After the monocalcium silicate solution is cooled, it is crushed into granules, and the monocalcium silicate fertilizer can be obtained. Others are the same as in Embodiment 1, omitted here.

Embodiment 3

[0013] Embodiment 3: the method for preparing this monocalcium silicate fertilizer, 1. use the fine white sand and lime water slurry that the glass factory cleans the raw material discharge to mix with 2: 1 by weight percentage, after manual or machine stirring, process into fine white sand ② Put the fine white sand, calcium carbonate stones and coke into the high-temperature furnace for smelting according to the weight percentage of 2:1:1. , the smelting temperature is above 3000°C, and the monocalcium silicate solution can be obtained continuously; ③ After the monocalcium silicate solution is cooled, it is crushed into granules, and the monocalcium silicate fertilizer can be obtained. Others are the same as in Embodiment 1, omitted here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com