Profiled short-pier shear wall with rung steel bar support

A technology of ladder grid reinforcement and special-shaped cross-section, applied in the direction of walls, structural elements, building components, etc., can solve the problem that there is no obvious improvement in the seismic energy consumption capacity of short-leg shear walls, there is not much application experience in earthquake areas, and the wall limbs have low seismic capacity. To achieve the effects of enhanced seismic energy dissipation capacity, enlarged crack distribution area, and improved torsional capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

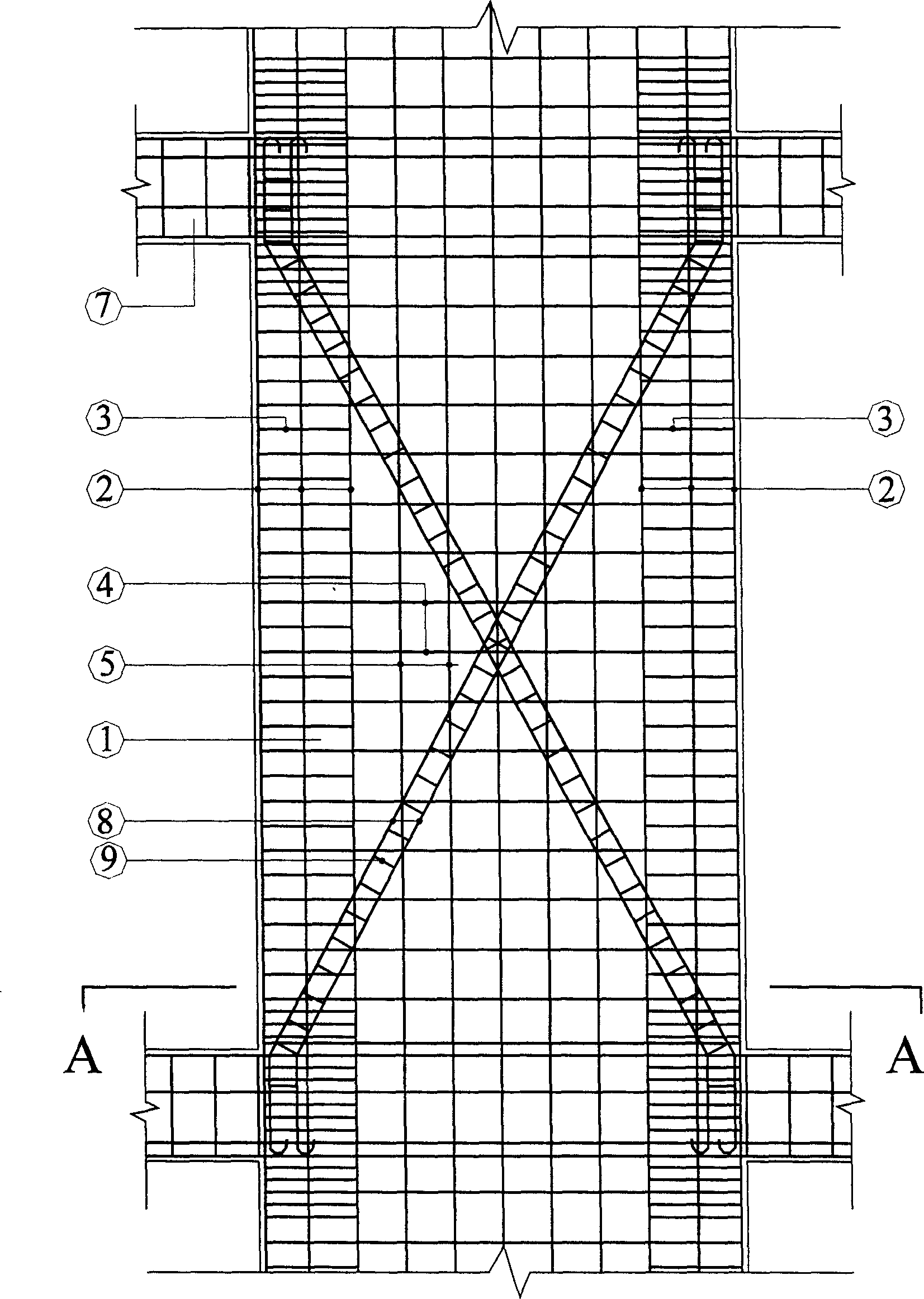

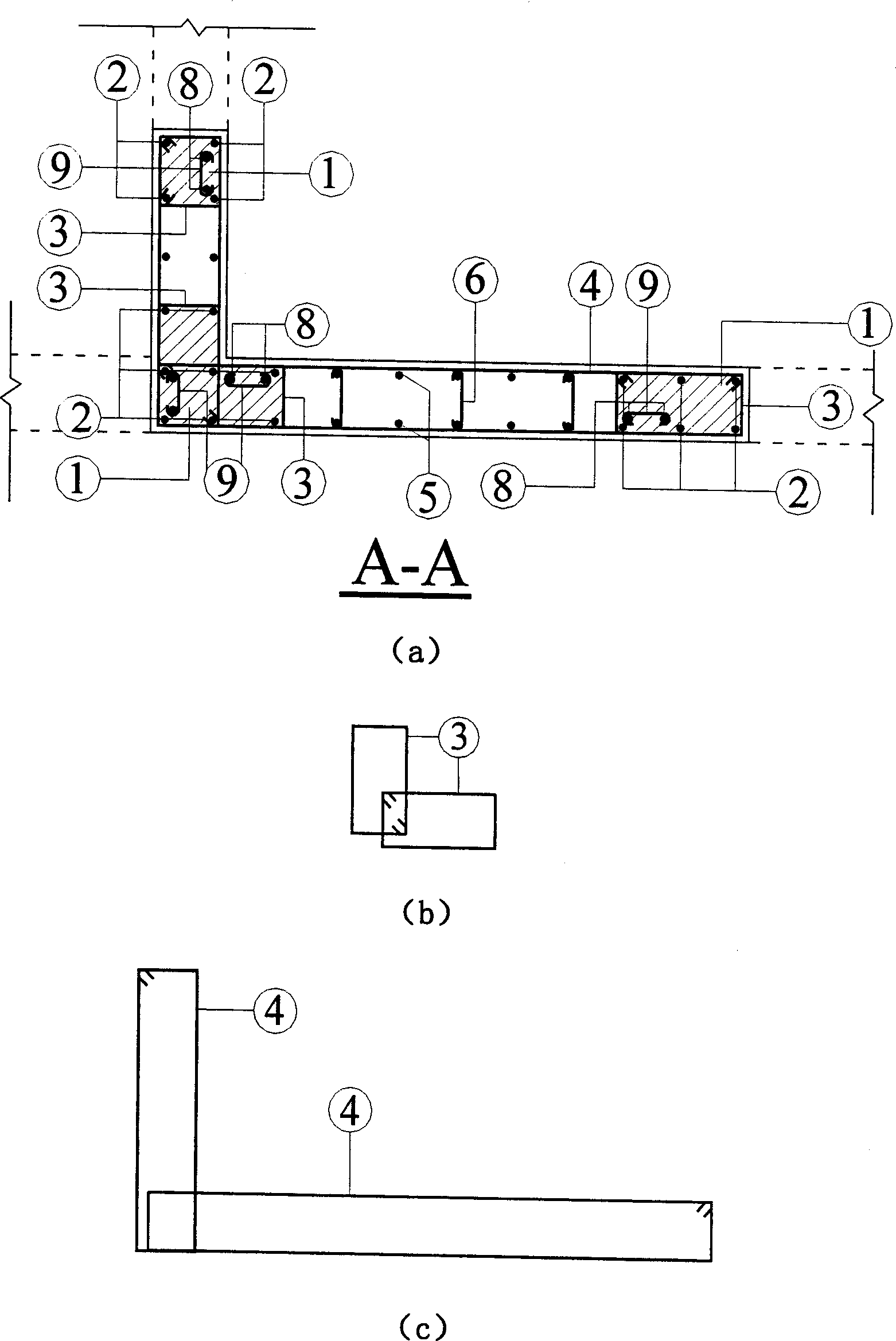

[0042] When the wall reinforcement adopts double-row reinforcement, the schematic diagram of the structural reinforcement of a structural unit of the L-shaped short-leg shear wall supported by ladder lattice steel bars is as follows figure 1 , figure 2 ,and image 3 As shown, it is composed of a reinforced concrete concealed column 1 and a shear wall panel supported by ladder bars; the reinforcement of the concealed column 1 is that rectangular stirrups 3 are evenly bound along the longitudinal steel bars 2, and the stirrups are along the entire concealed column. Bundle, and intensify in the anchorage area of the oblique steel tendon 8, the concealed column at the corner of the wall is L-shaped, and the stirrup of the concealed column at the corner is a vertical rectangular stirrup to form an L-shape; the distribution of the shear wall panel The reinforcement is that horizontally distributed steel bars 4 and longitudinally distributed steel bars 5 are evenly arranged on bo...

Embodiment 2

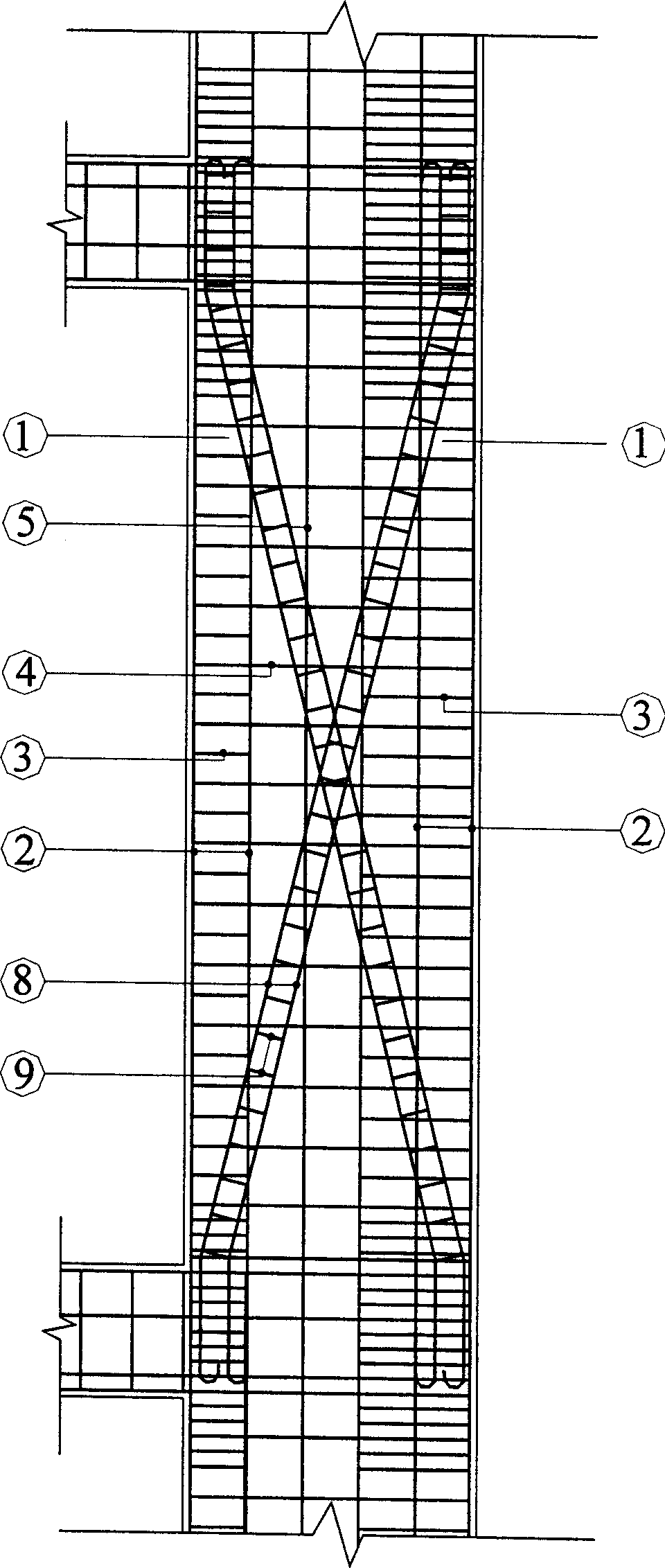

[0044] When the wall reinforcement adopts double-row reinforcement, the schematic diagram of the structural reinforcement of a structural unit of the T-shaped short-leg shear wall supported by ladder lattice steel bars is as follows Figure 4 , Figure 5 ,and Figure 6 As shown, it is composed of a reinforced concrete concealed column 1 and a ladder steel bar supporting shear wall panel; the reinforcement of the concealed column 1 is the same as that of Example 1, and the concealed column at the corner of the wall is T-shaped, and the corner is The hidden column stirrups are vertical rectangular stirrups arranged in a T shape; the reinforcement of the shear wall panels is the same as that of Example 1; Bind one-way oblique tendons 8 respectively. The oblique tendons 8 on each side of the web are composed of three parallel reinforcing bars, and the oblique tendons 8 on each side of the flange are composed of two parallel reinforcing bars. Tension reinforcements 9 perpendicula...

Embodiment 3

[0046] When the wall reinforcement adopts double-row reinforcement, the cross-sectional enlarged schematic diagram of a structural unit of the special-shaped cross-section Z-shaped short-leg shear wall supported by ladder lattice steel bars is as follows Figure 7 As shown, it is composed of reinforced concrete concealed column 1 and steel bar support shear wall panel with ladder; the reinforcement of its concealed column 1 is the same as that of embodiment 1, and the reinforcement of shear wall panel is the same as that of embodiment 1; the ladder The bars supported by the grid steel bars are the same as in Example 1, and the concrete is poured and tamped to form a Z-shaped short-leg shear wall with a ladder grid steel bar support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com