Loom drive mechanism and control system thereof

A technology of transmission mechanism and control system, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficulty in meeting, high manufacturing cost, long time, etc., achieve quick start and braking, low manufacturing cost, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

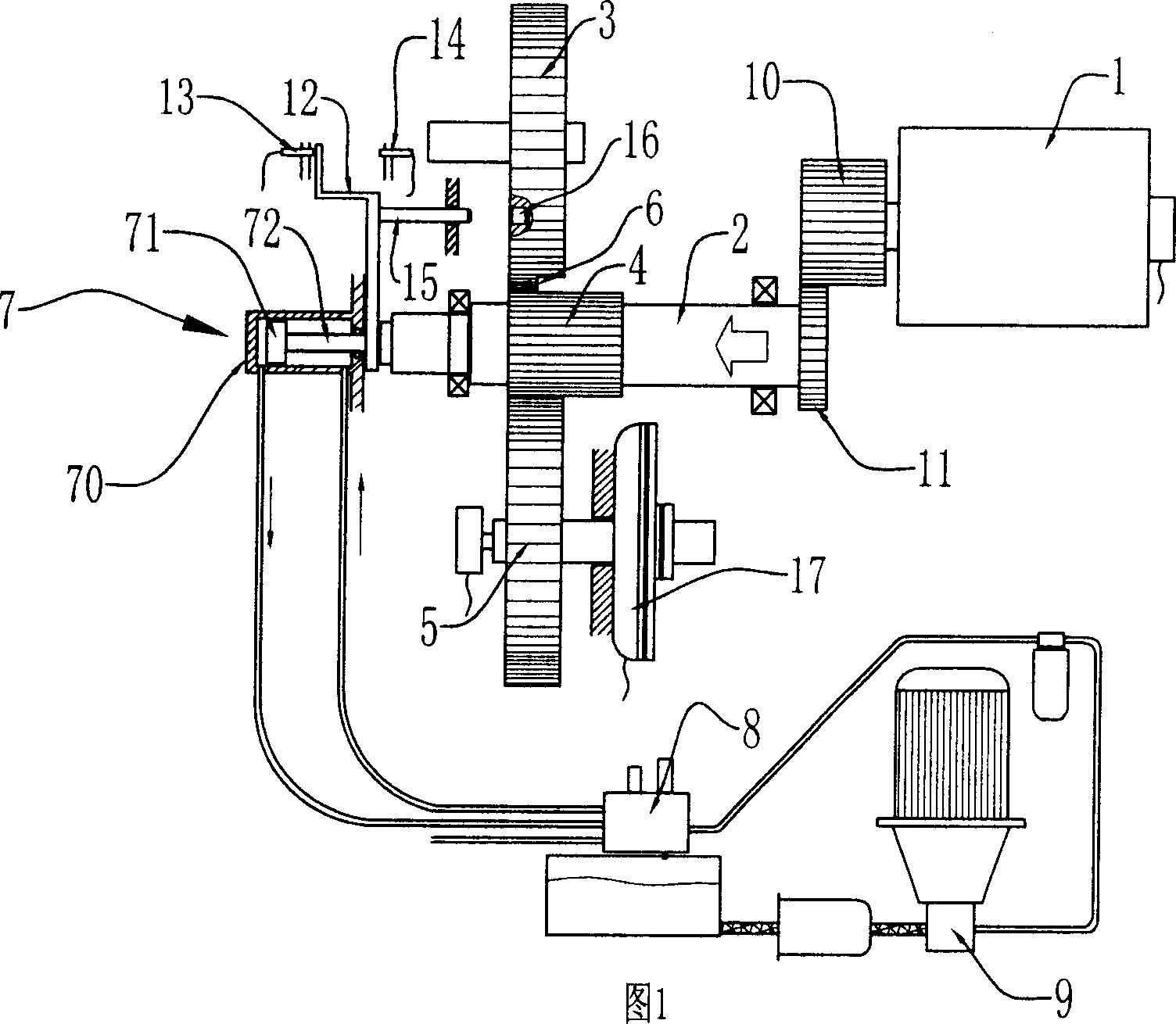

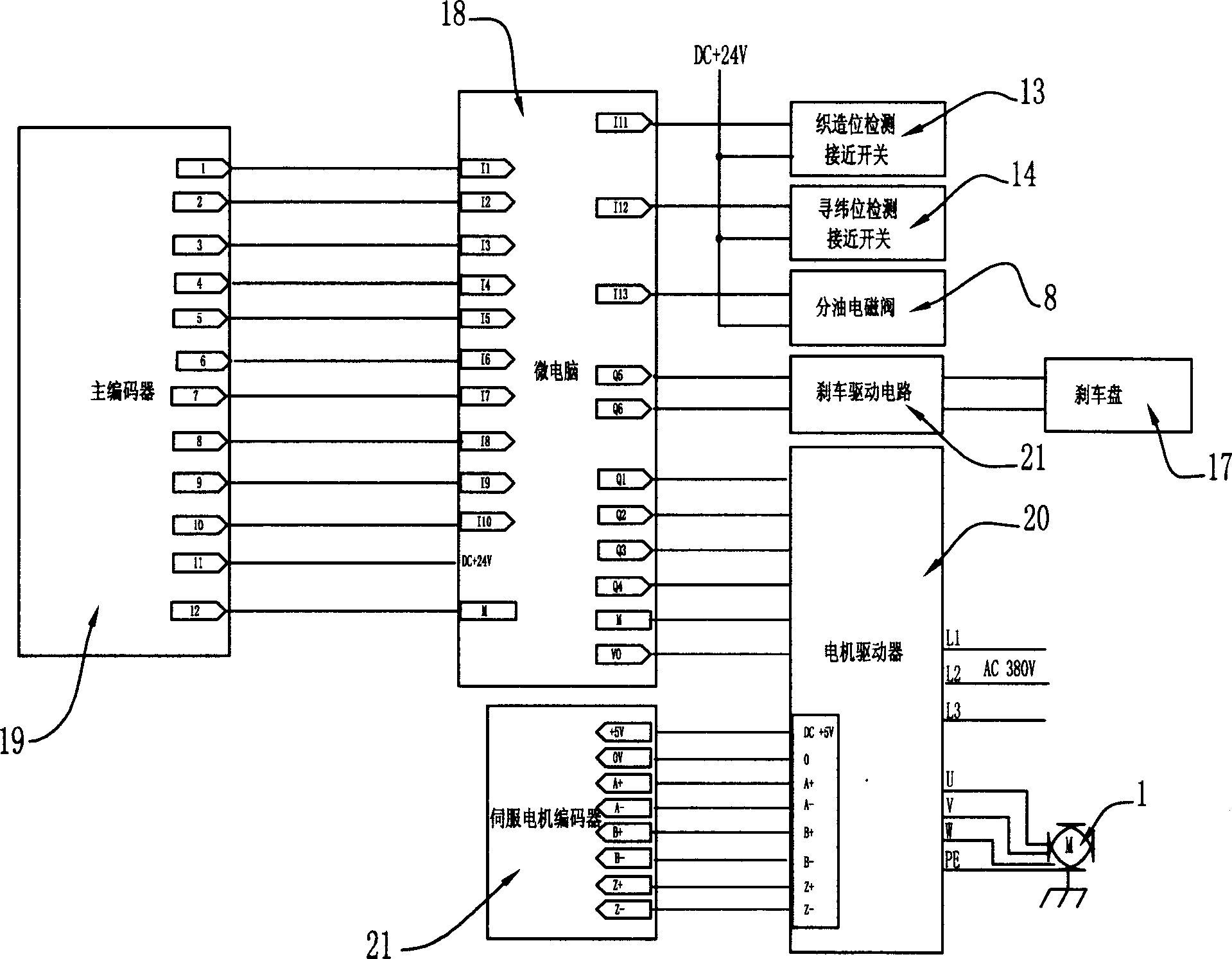

[0020] Embodiment 1, as shown in Figure 1, according to the transmission mechanism of a kind of loom of the present invention, comprise main motor 1 and main shaft 2, main motor 1 and main shaft 2 are meshed by gear, main shaft gear 11 can be relative to main motor gear 10 shafts The main motor 1 is a servo motor, and the main shaft 2 is equipped with a main shaft transmission gear 3. The upper and lower sides of the main shaft transmission gear are respectively meshed with the transmission gear 4 of the weft insertion and beating mechanism and the transmission gear 5 of the shedding mechanism. 4, 5 and the meshing part of the main shaft transmission gear 3 are completely overlapped, a gap 6 is provided on one side of the transmission gear 4 of the weft insertion and beating-up mechanism, and a hydraulic cylinder 7 is provided at one end of the main shaft 2, and the piston 71 is placed in the cylinder body 70 and passed through the rod Part 72 is connected to the main shaft, an...

Embodiment 2

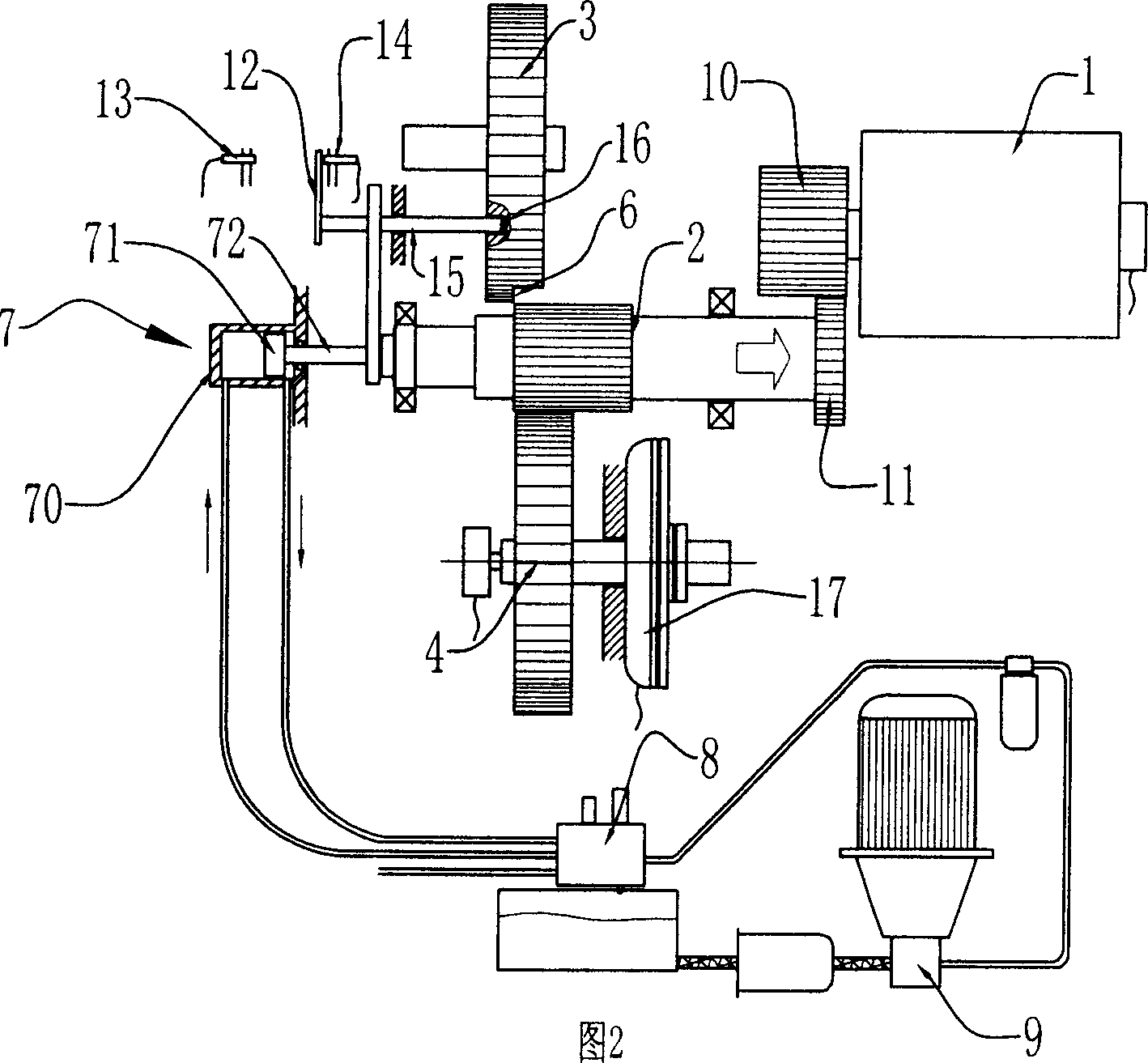

[0032] Embodiment 2, according to the transmission mechanism of another kind of loom of the present invention, it differs from Embodiment 1 in that the meshing parts of weft insertion, beating-up mechanism transmission gear 4 and shedding mechanism transmission gear 5 and main shaft transmission gear 3 are not completely coincident. Figure 5 It is the situation that the meshing parts of the weft insertion and beating-up mechanism transmission gear 4 and the shedding mechanism transmission gear 5 and the main shaft transmission gear 3 are completely staggered. Image 6 It is the situation that the meshing parts of the transmission gear 4 of the weft insertion and beating-up mechanism, the transmission gear 5 of the shedding mechanism and the main shaft transmission gear 3 are partially staggered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com