Phosphoric acid production system

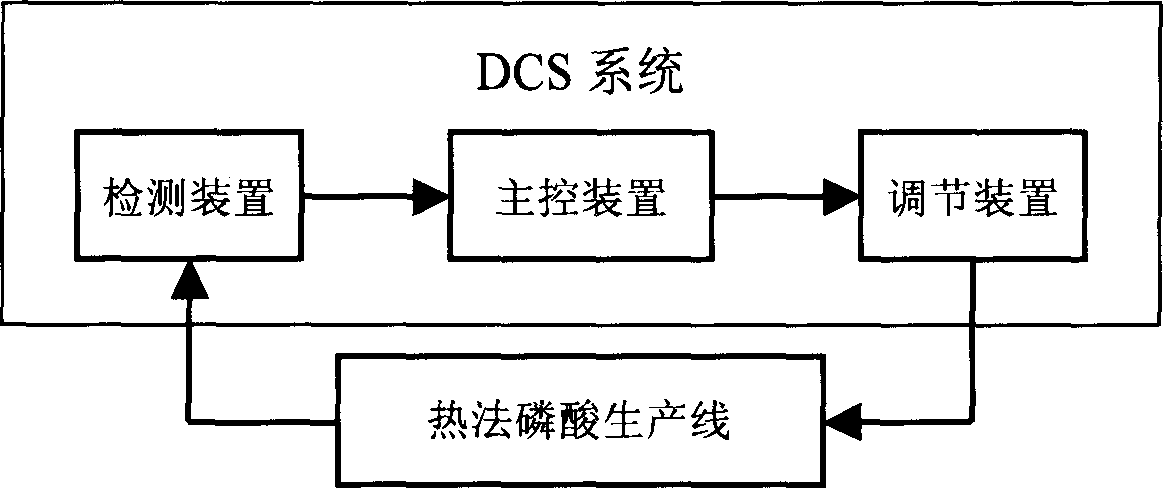

A production system, phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., can solve the problems of easy error in human control, large amount of process parameter control, unstable product quality, etc., to improve detection accuracy and control accuracy, and realize Effect of automatic control and reduction of accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

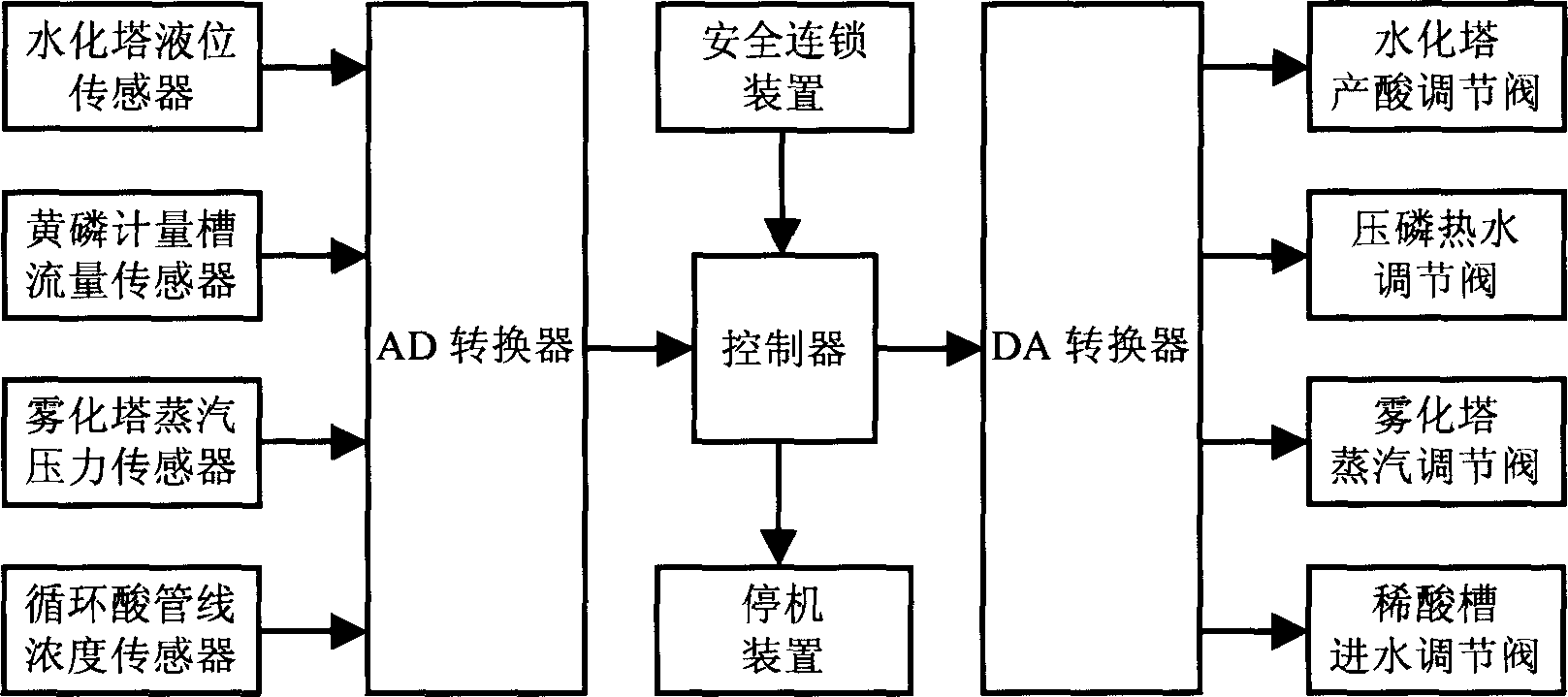

[0013] In this example, a digital control system is selected, and the main control device consists of AD converter, DA converter, controller and operation station. System structure see figure 2 . The input end of the AD converter is connected with the detection device, and the detected process parameters are digitized and then input into the controller. The controller compares the input data with the set value, and after internal program operation processing, outputs the digital control signal to the DA converter. Process parameters are adjusted. At the same time, the image interface of each relevant detection and adjustment process is displayed in real time at the operation station through the bus, and the operator can also control the system at the operation station.

[0014] The digital control system has the advantages of parameter detection, high control precision and strong anti-interference ability.

Embodiment 2

[0016] The structure diagram of the DCS system in this example is as follows: image 3 , the figure shows the process parameter detection points and control points of the main process of the thermal phosphoric acid production line. The following is a detailed description of the DCS system in this example according to the process flow of the production line:

[0017] 1. Liquid level control of the hydration tower: The hydration tower is the main equipment for the production of thermal phosphoric acid. After the yellow phosphorus is burned in the hydration tower, it reacts with water to form dilute phosphoric acid, which is then refluxed through the circulating acid pump, so that the dilute acid returns to the hydration tower to form a film, and the water in the dilute acid is continuously mixed with P 2 o 5 The reaction generates phosphoric acid, so that the concentration of the acid is continuously increased. When the concentration reaches 82% (the existing pentasodium produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com