Guava processing method

A processing method, the technology of guava, applied in the field of processing guava by ultrafiltration technology, can solve the problems that cannot be proposed and utilized, and achieve the effects of increasing comprehensive utilization rate, good clarity, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

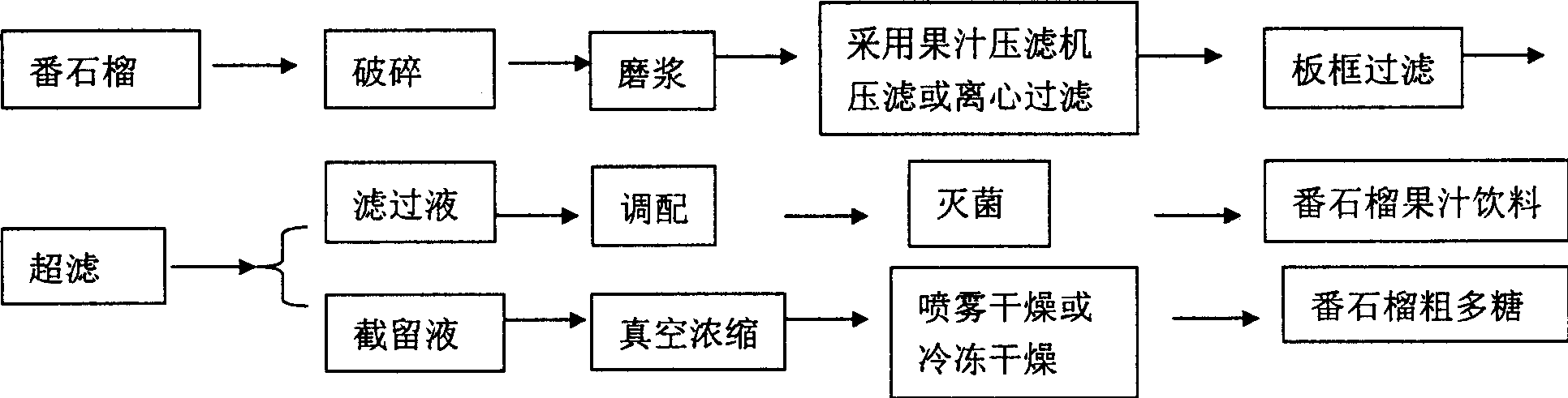

[0019] Such as figure 1 Shown, guava processing method of the present invention is as follows:

[0020] a) Fragmentation of guava: 100Kg of guava fruit is cut into small pieces, and crushed into pieces with a stainless steel crusher.

[0021] b) defibrination of guava: add 200Kg of water filtered through sand and activated carbon to the crushed guava fruit, and use colloid mill to grind into pulp to obtain 300Kg of guava pulp.

[0022] c) Filtration of guava pulp: filter the finely ground guava pulp with a juice filter press to obtain 250Kg of light gray-green guava extract.

[0023] d) Filtration of the guava extract: filter the guava extract by using a plate-and-frame filter to remove insoluble solids therein.

[0024] e) Ultrafiltration: Use an ultrafiltration device with a molecular weight cut-off of 10KDa or 20KDa to carry out ultrafiltration and separation of the guava extract until the filtrate reaches 200L, add 50L of pure water to the retained liquid, and perform ul...

Embodiment 2

[0028] a) Fragmentation of guava: Cut 5Kg of guava fruit into small pieces, and grind it into pieces with a food processor.

[0029] b) Refining of guava: Add 15 L of water filtered through sand and activated carbon to the crushed guava fruit grains, and use colloidal grinding to grind into pulp to obtain 20 L of guava pulp.

[0030] c) Filtration of guava pulp: filter the finely ground guava pulp with a centrifugal filter to obtain 17 L of light gray-green guava extract.

[0031] d) Filtration of the guava extract with a plate-and-frame filter: filter the guava extract with a plate-and-frame filter to remove insoluble solids therein.

[0032] e) Ultrafiltration: Use an ultrafiltration device with a molecular weight cut-off of 5KDa to carry out ultrafiltration and separation of the guava extract to a filtrate of 12L, add 5L of pure water to the retentate, and perform ultrafiltration again to obtain a secondary filtrate of 8L , combined two ultrafiltration filtrates to obtain ...

Embodiment 3

[0036] According to the operation in Example 2, 10 L of water and 3.5 g of sucralose were added to the obtained ultrafiltration filtrate 10 L (the addition of sucralose ensures that the sweetness of the beverage is equivalent to the sweetness of 9 to 11% sucrose) , citric acid 0.01kg, its add-on is 0.05% of the guava fruit juice drink weight, guava essence 0.002kg (the guava essence add-on is the 0.01% of the guava fruit drink weight.) Allotment, the filtrate after allotment Adopt 121 ℃, 8min heat sterilization, make guava juice drink 20L.

[0037] Other steps are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com