Laser impulse amplification system

A technology for amplifying systems and laser pulses, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of bulky systems, failure of laser oscillators, high costs, etc., and achieve high system reliability and reliability. Improved, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

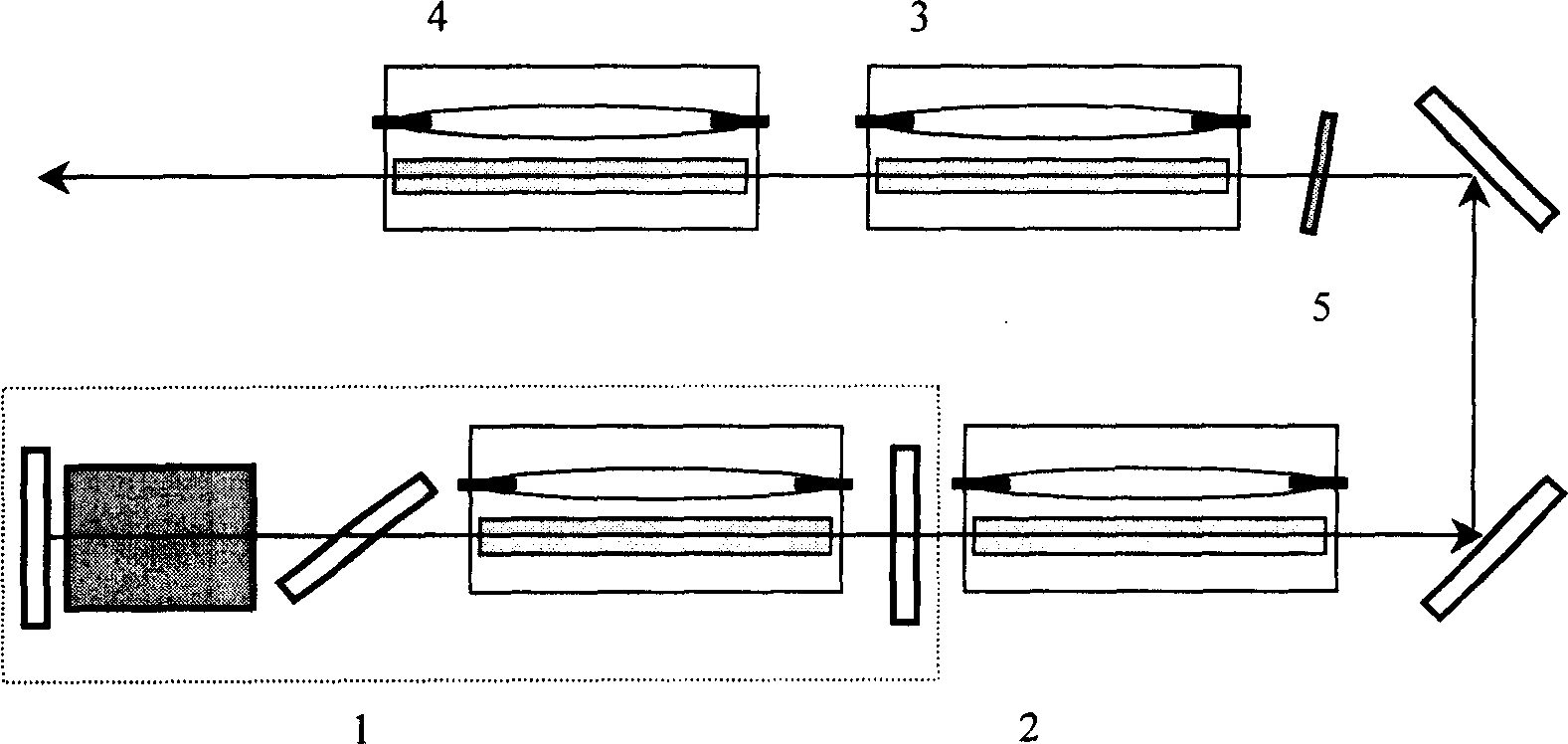

[0021] Referring to the accompanying drawings, it is a preferred embodiment of the present invention when a Q-switched laser oscillator 1 and a three-stage amplifier are used, and a saturable absorber 5 is inserted between the first-stage amplifier 2 and the second-stage amplifier 3 . Since the weak optical signal in front of the Q-switched laser main pulse is not very strong, it is not significantly enhanced when passing through the first-stage amplifier 2; while the spontaneous emission optical signals of the second-stage amplifier 3 and the third-stage amplifier 4, If there is no coupling with the first-stage amplifier 2, no effective amplification will be obtained. Therefore, placing the saturable absorber 5 between the first-stage amplifier 2 and the second-stage amplifier 3 can completely eliminate the interstage coupling between the amplifiers and eliminate the weak light in front of the Q-switched laser pulse signal, making the Q-switched Laser pulses are effectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com