Metal halide lamp and lighting device using same

A metal halide lamp, metal halide technology, applied in the direction of lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of color rendering loss, reduce vapor pressure, etc., and achieve the effect of preventing color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The best mode for carrying out the present invention will be described below with reference to the accompanying drawings.

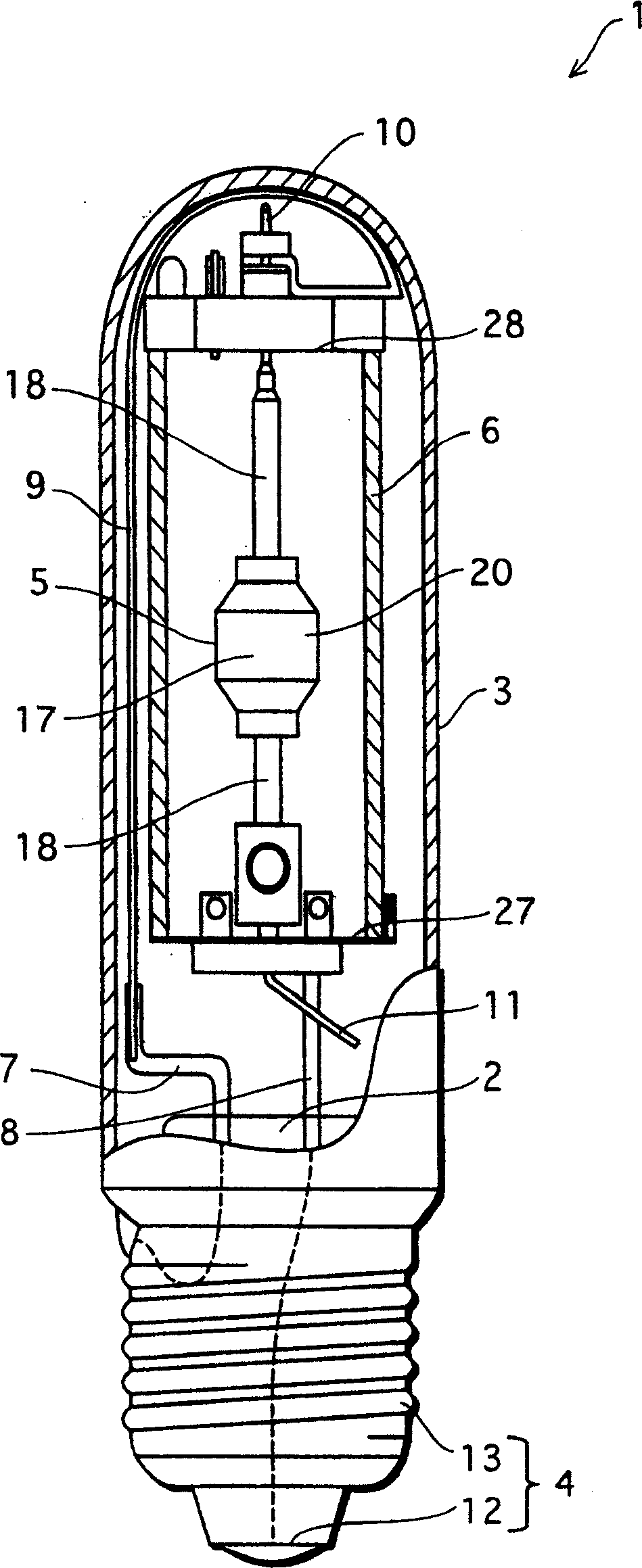

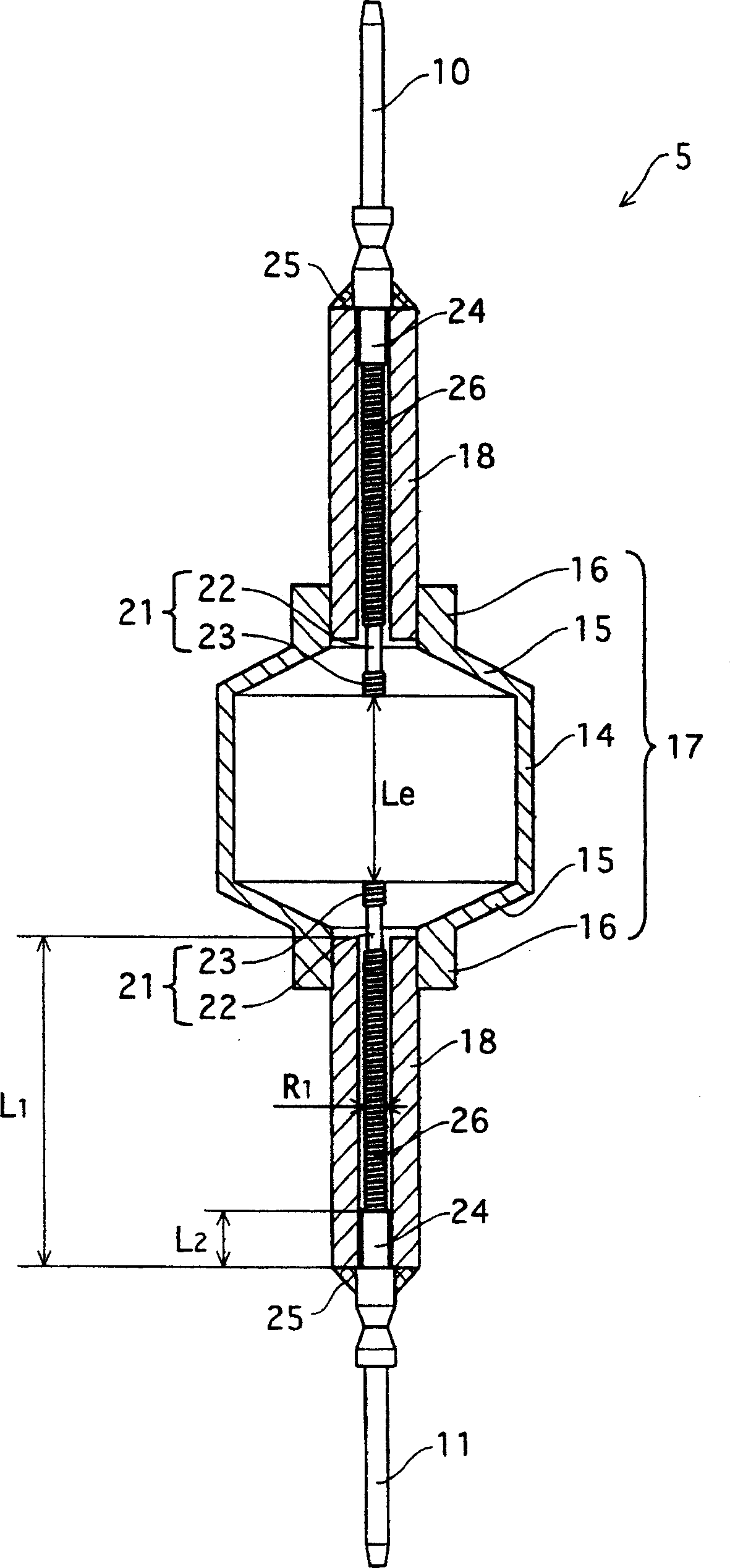

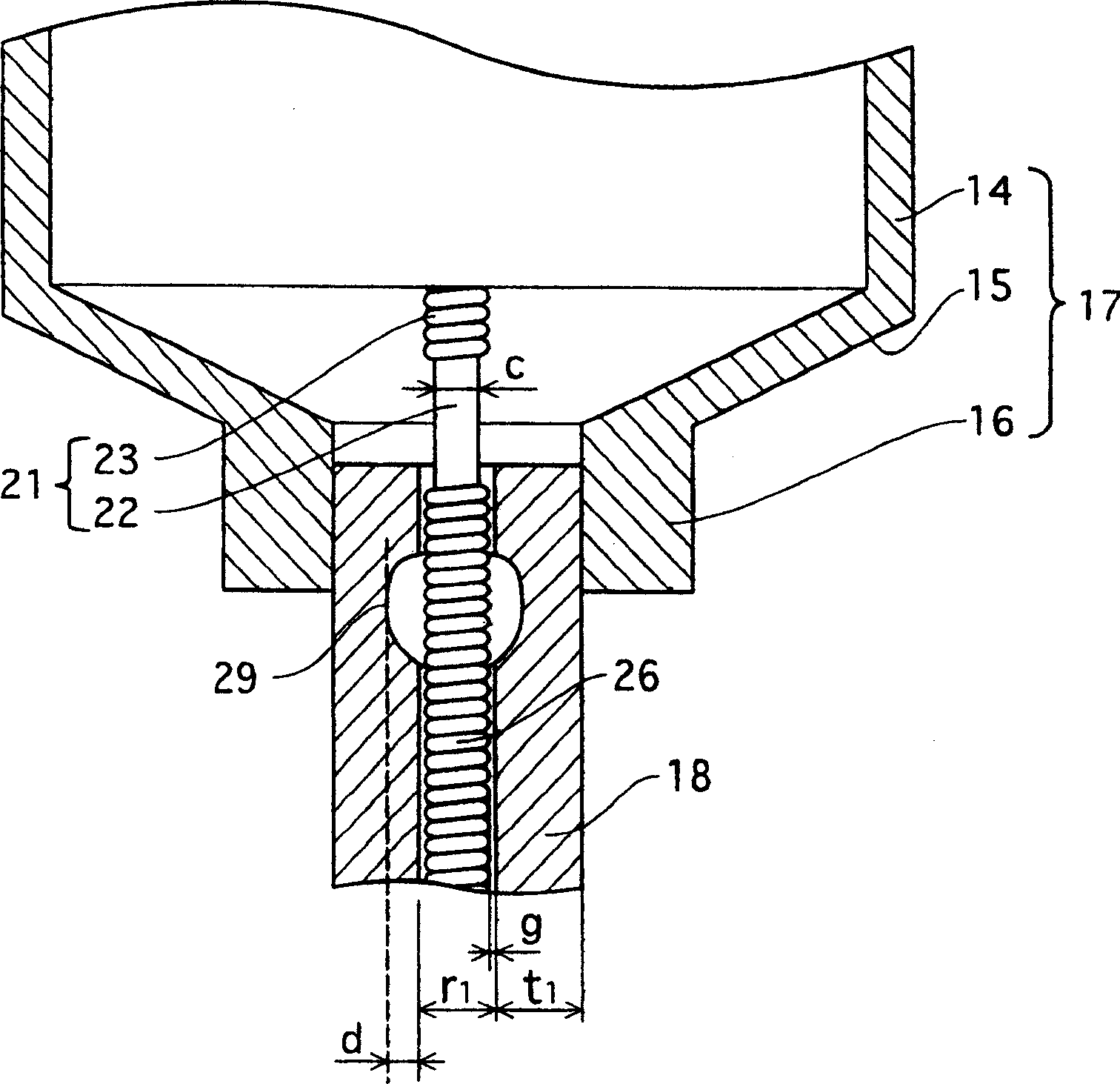

[0029] figure 1 A dimmable metal halide lamp 1 according to an embodiment of the invention is shown. Such as figure 1 As shown, the metal halide lamp 1 includes: an outer tube 3 (for example, made of hard glass), one end of which is closed and substantially hemispherical, and the other end is sealed by a tube base 2; a lamp base 4 (for example, an E-type lamp base) connected to To one end of the outer tube 3 sealed by the base 2; the arc tube 5 is arranged inside the outer tube 3; the sleeve 6 made of quartz glass is in a tubular shape. The sleeve 6 is inserted between the outer tube 3 and the arc tube 5, thereby preventing the outer tube 3 from breaking when the arc tube 5 breaks.

[0030] The metal halide lamp 1 has a standard rated power of 150 W (ie maximum lamp power) and a minimum lamp power of 90 W is used in the case of dimming control. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com