Feed shaft bearing block structure of flat pressing continuous press

A fixing method and bearing seat technology, applied in the direction of shafts and bearings, bearing elements, rigid supports of bearing components, etc., can solve the problems of the development of wood-based panels, unfavorable maintenance, maintenance work, shortened service life, etc., to achieve easy adjustment, The effect of prolonging the service life and facilitating lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

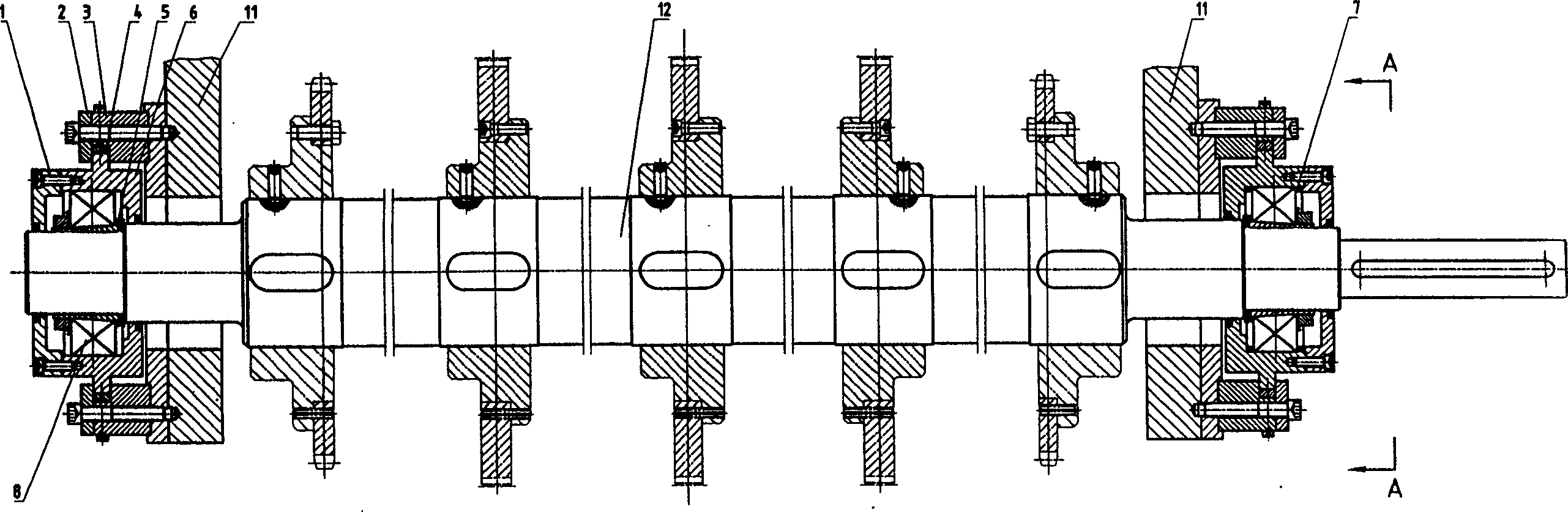

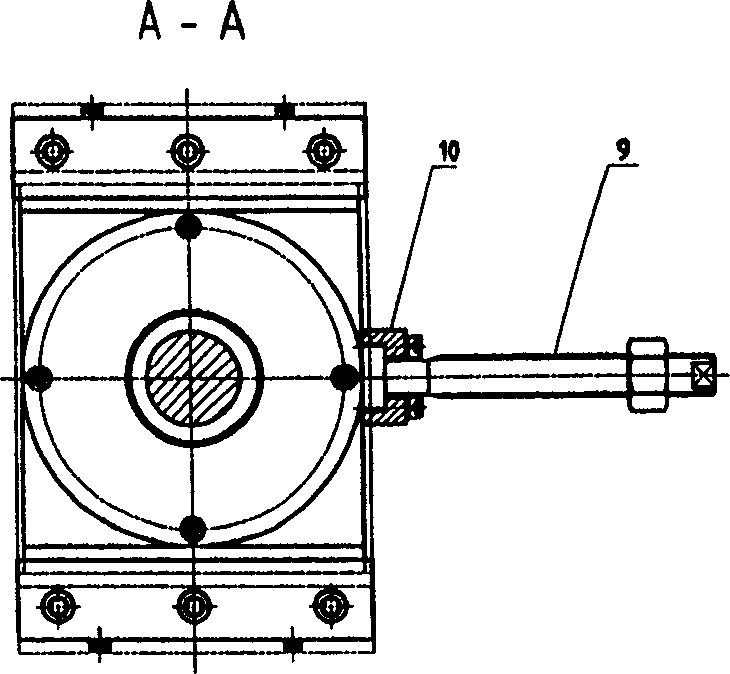

[0017] An example of the present invention is to produce the feed shaft bearing block structure (as figure 1 , figure 2 Shown), mainly by bearing cover 1, pressure plate 2, plate 3, liner plate 4, inner locating ring 5, bearing seat 6, outer locating ring 7, bearing 8, screw rod 9 and connecting plate 10 and other parts. The plate 3 is installed in the notch of the welding plate outside the feed head bracket, and its stepped surface is connected with the lining plate 4, and the outer side is pressed with the pressure plate 2 to form two guide rail grooves. The guiding length of the guide rail groove is 300mm, and the material of the plate 3 is Q235, the material of liner 4 is 45, and the material of pressure plate 2 is Q235. Bearing seat 6 material is 35, and two boss guide rails up and down can slide in guide rail groove. Bearings 8 at both ends use SKF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com