Bearing air cylinder, compressor and air conditioner

A technology for compressors and cylinders, applied in the field of compressors, can solve problems such as abnormal wear, unreasonable design of relevant parameters, and poor compressor compression energy efficiency, and achieve the effects of reducing abnormal wear, facilitating lubrication, and improving energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

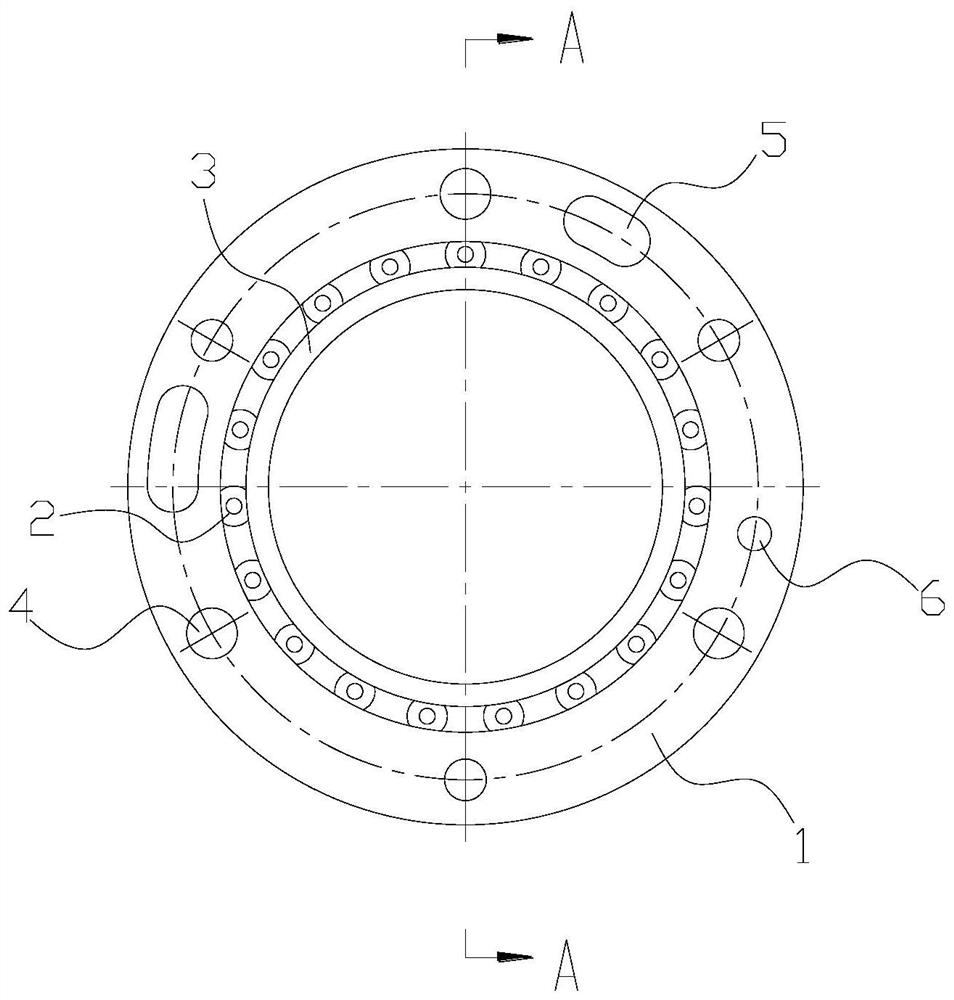

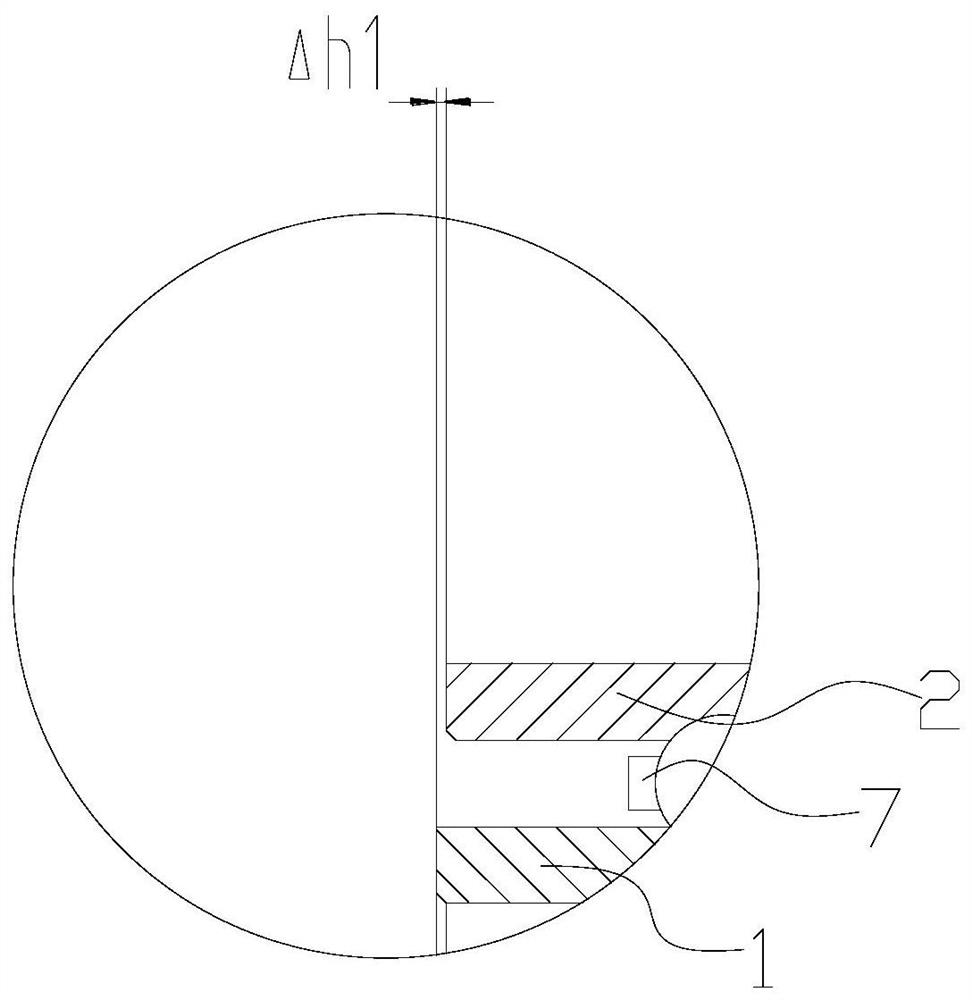

[0027] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the bearing cylinder includes an outer ring 1, a rolling body 2 and an inner ring 3, the rolling body 2 is rotatably arranged between the outer ring 1 and the inner ring 3, and the outer ring 1 is arranged axially through There are screw avoidance holes 4 , compressed medium circulation channels 5 and lubricating oil circulation channels 6 , and the lubricating oil circulation channels 6 are configured to deliver lubricating oil to the cavity between the outer ring 1 and the inner ring 3 .

[0028] The bearing cylinder is provided with a lubricating oil circulation channel 6 on the outer ring 1, and the lubricating oil circulation channel 6 can be used to deliver lubricating oil to the rolling element installation cavity between the outer ring 1 and the inner ring 3, so that the rolling element 2 can be conveniently carried out. Lubrication reduces motion resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com