Liquid crystal display capable of preventing short circuit of electric gold ball, and preparation method

A technology of liquid crystal display and conductive gold ball, which is applied in the direction of static indicators, etc., to achieve the effect of simple control and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

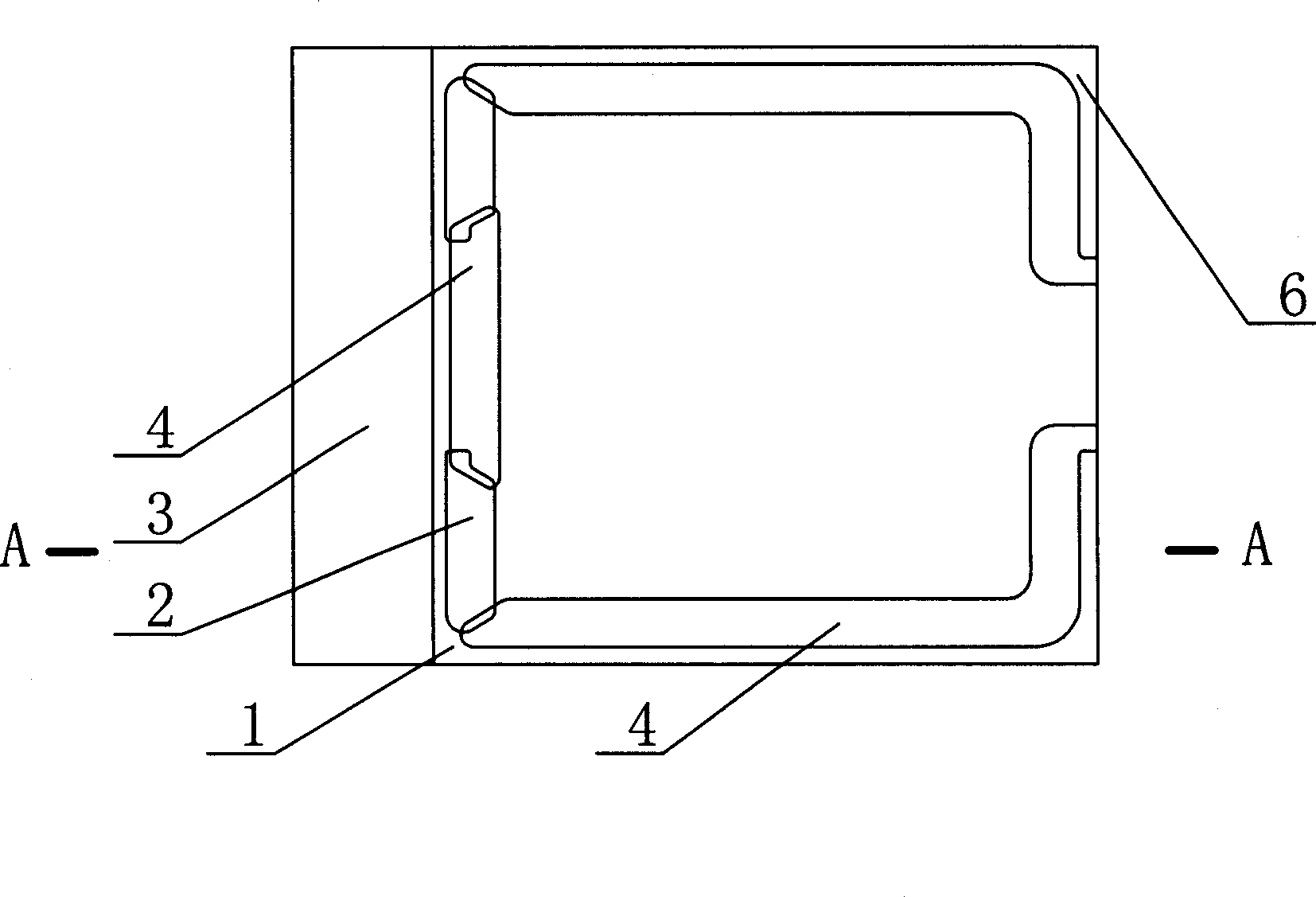

[0051] A liquid crystal display that prevents short-circuiting of conductive gold balls

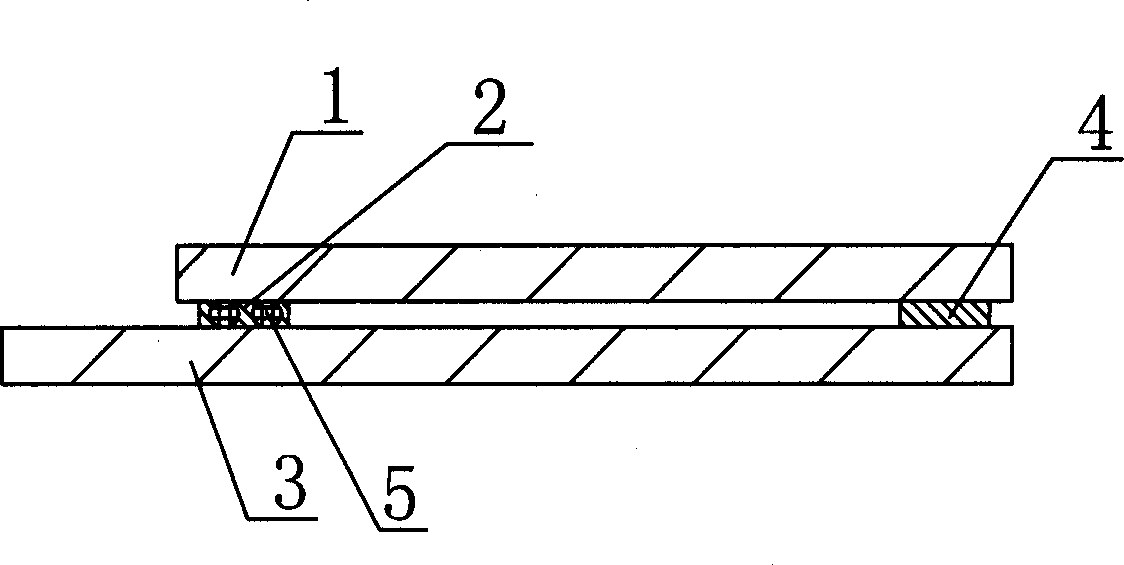

[0052] The liquid crystal empty box 6 is formed by spraying gaskets on the transfer point 2 made of the upper ITO glass substrate 1 and the sealant frame 4 made of the lower ITO glass substrate 3 respectively, aligning and laminating them, and then hot pressing and curing. The transfer point 2 is set in a small part of the frame area where the row and column electrodes of the upper and lower ITO glass substrates need to be transferred and conducted, that is, the row electrodes are led out, and is made of a transfer sealant dispersed with conductive gold balls 5 by screen printing , the sealant frame 4 is arranged in most frame ranges where the row electrodes do not need to be drawn out, and is made of screen-printed sealant.

[0053] The design width of the transfer point 2 is 0.27mm, and the design width of the sealant frame 4 is 0.30mm, which matches the design width of the transfer poi...

specific Embodiment approach 2

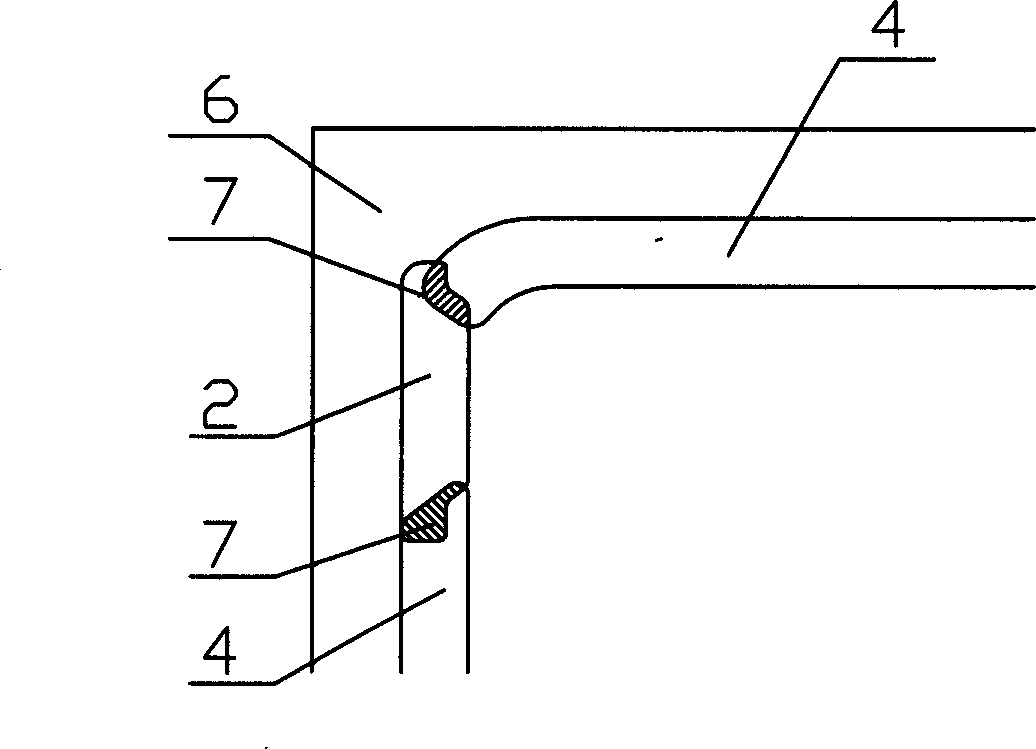

[0056] Another liquid crystal display that prevents conductive gold balls from shorting

[0057] The design width of the transfer point 2 is 0.27 mm, and the design width of the sealant frame 4 is 0.30 mm, which matches the design width of the transfer point 2 to ensure that the overlapping part 7 of the transfer point 2 and the sealant frame 4 is hot-pressed and expanded. The width is equal, and the shape of the joint part 8 between the transfer point 2 and the sealant frame 4 is a complementary shape that ensures that the overlapping part 7 of the transfer point 2 and the sealant frame 4 will not be glued and not enlarged after thermal expansion. The shape is For the combined shape of trapezoid and square, the overlapping portion 7 has a maximum width of about 0.25mm.

[0058] The manufacturing method of the present invention is used to screen-print the frame, the operating temperature is 23° C., the relative humidity is 65%, the screen printing pressure is 0.2-0.3 MPa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com