Separation method for refining coarse piperyene

A separation method and technology for piperylene are applied in the field of refining and separation of crude piperylene, which can solve the problems of no use value, failure to be recycled, and low purity, reduce waste liquid discharge, and be beneficial to environmental protection. , Improve the effect of refining yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

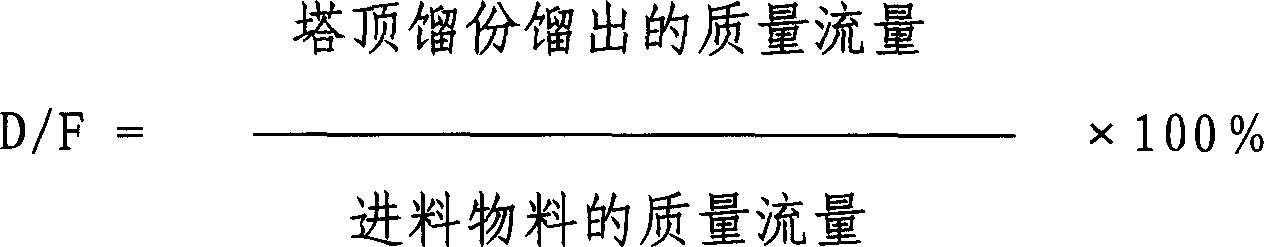

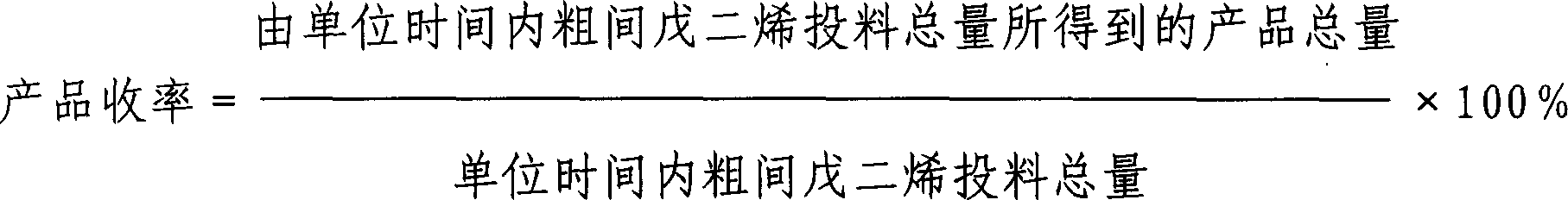

[0029] The crude piperylene whose composition is shown in Table 1 is preheated to 30-40° C. and then enters an extractive distillation column for extractive distillation. The extractive distillation column is a packed column with 45 theoretical plates. Crude piperylene enters the extractive distillation column from the 32nd tray at a flow rate of 400g / h, and the extractant is fed from the 4th tray. The extraction and rectification towers of each embodiment are operated under normal pressure. The specific extraction agent used, the feed weight ratio of piperylene to the extraction agent, and the temperature of the tower bottom and tower top are shown in Table 2. The main composition of the material discharged from the top of the extractive distillation tower in each embodiment is shown in Table 3.

[0030] The extractive distillation tower bottom material enters a rectification tower subsequently to carry out rectification, and the rectification tower is a packed tower, and the...

Embodiment 8~11

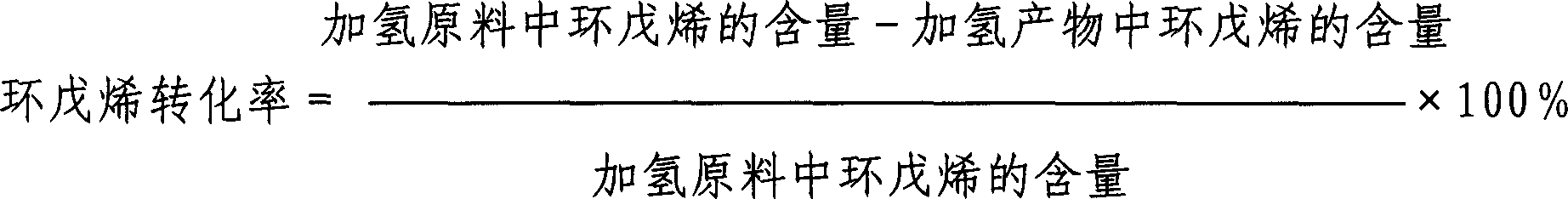

[0037] The tower top material obtained in Step 1 of Example 1 (the composition is shown in Table 3) is mixed with hydrogen and enters a fixed-bed catalytic hydrogenation reactor for hydrogenation reaction to obtain cyclopentane. The catalyst adopts Pd / γ-Al 2 o 3 (The content of Pd in the catalyst is 0.5wt%, the catalyst is spherical, and the particle size is 2-4mm). See Table 6 for the process conditions used in each embodiment and the hydrogenation conversion rate of cyclopentene.

[0038] volume feed ratio

[0039] Note: The volume feed ratio is: hydrogen / overhead material

Embodiment 9

[0041] The hydrogenated product obtained in Example 9 (with a cyclopentane content of 72 wt%) was preheated to 40° C. and then entered a rectification tower for rectification. The rectification tower was a packed tower with 35 theoretical plates. The hydrogenation product enters the rectification tower from the 14th tray at a flow rate of 100g / h, the light component material is distilled from the top of the tower, and the refined product of cyclopentane is obtained in the bottom of the tower. The rectifying towers of each embodiment are operated under normal pressure, and other process conditions and cyclopentane product purity are shown in Table 7.

[0042] Top temperature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com