Method for structuring teeth parts of improved bicycles and vehicles

A technology for bicycles and spokes, which is applied to vehicle parts, spoked wheels, wheels, etc., and can solve problems such as difficult locking of spoke caps and reduced production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

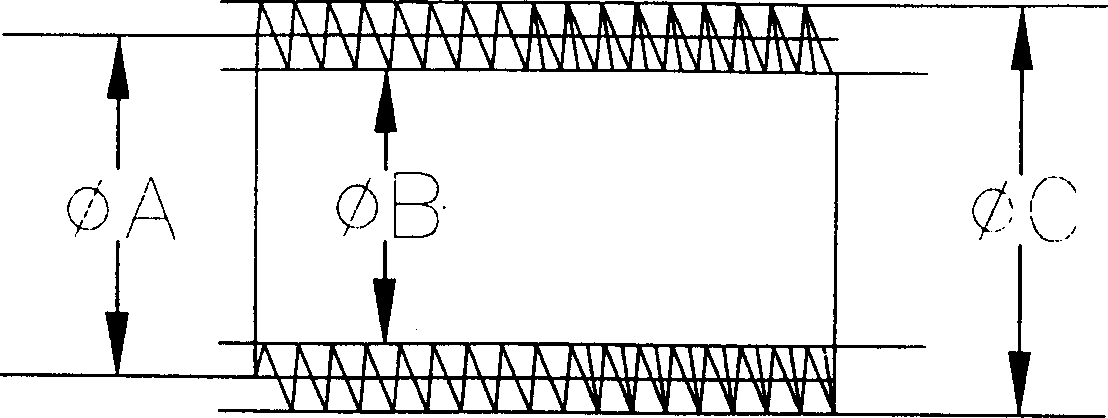

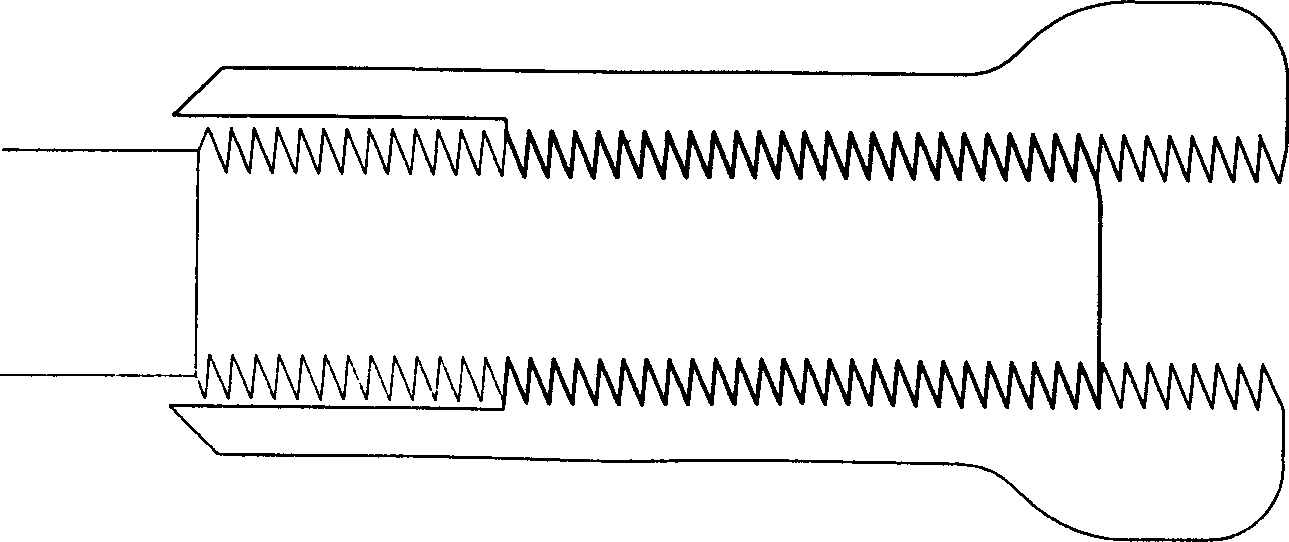

[0028] The present invention provides a method for improving the structure of the spoke teeth of bicycles and locomotives. The method uses mechanical processing to increase the structural strength of the teeth 11 of the spoke body 1 and improve its shape; image 3 As shown, it is the spoke body structure 1 comprising the elbow 10 and the reinforced tooth 11 structure made by the method of the present invention; now the preferred embodiments are listed, and then the present invention is fully described:

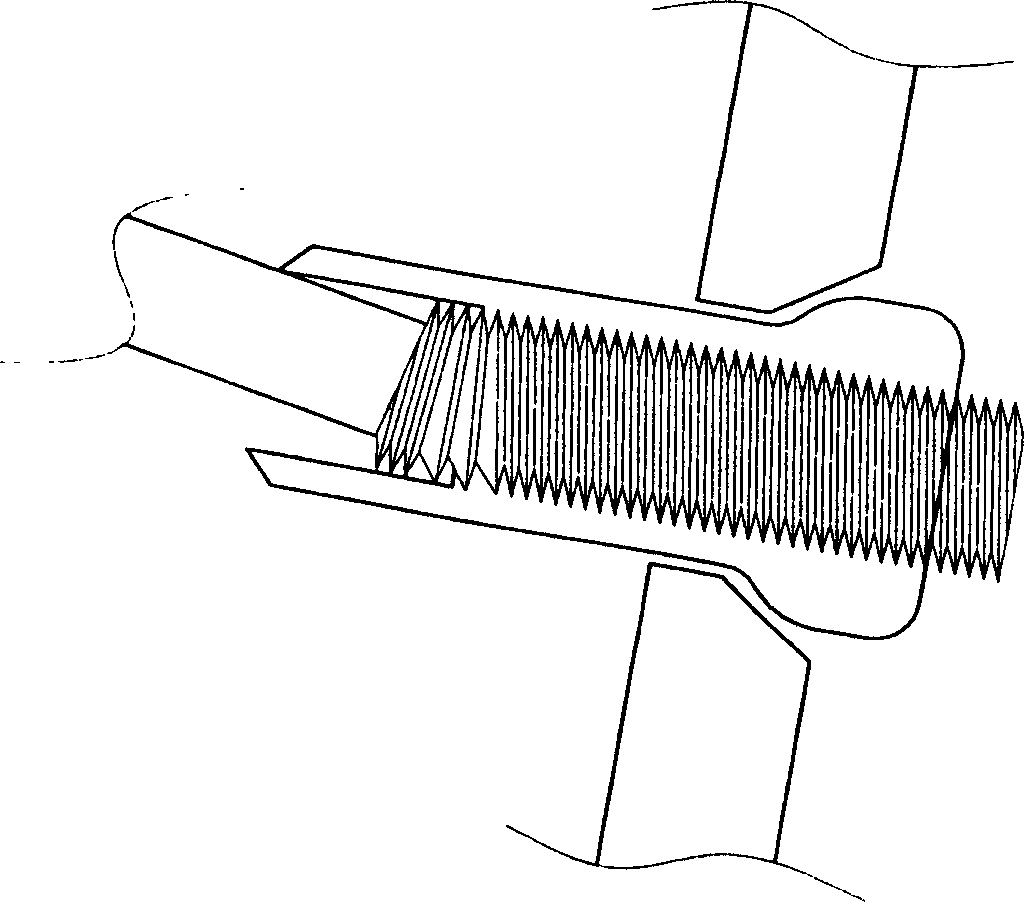

[0029] First, for an introduction to the method, see Figure 3 ~ Figure 5 As shown, the equipment used at least includes clamping die 2, punching die 3, dental machine 4, etc., and the steps are as follows:

[0030] A. Utilize the upper and lower clamping dies 20 and 21 of the clamping die 2 to clamp the wire 5, and make the punching die 3 approach the clamping die 2 forward;

[0031] B. The inner mold 30 of the punching die 3 contacts the clamping die 2, and the striker 31 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com