Method of determining pipeline welding crack stress concentration using metal magnetic memory detection technology

A metal magnetic memory and stress concentration technology, applied in welding equipment, metal processing equipment, material magnetic variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

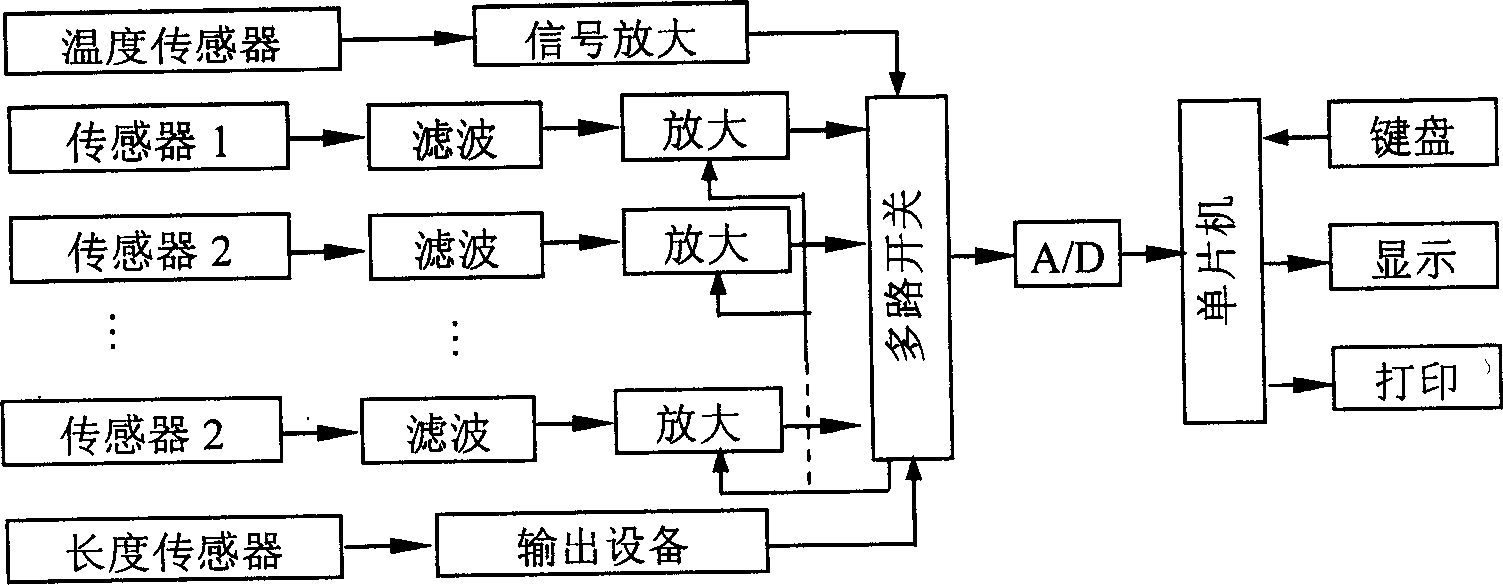

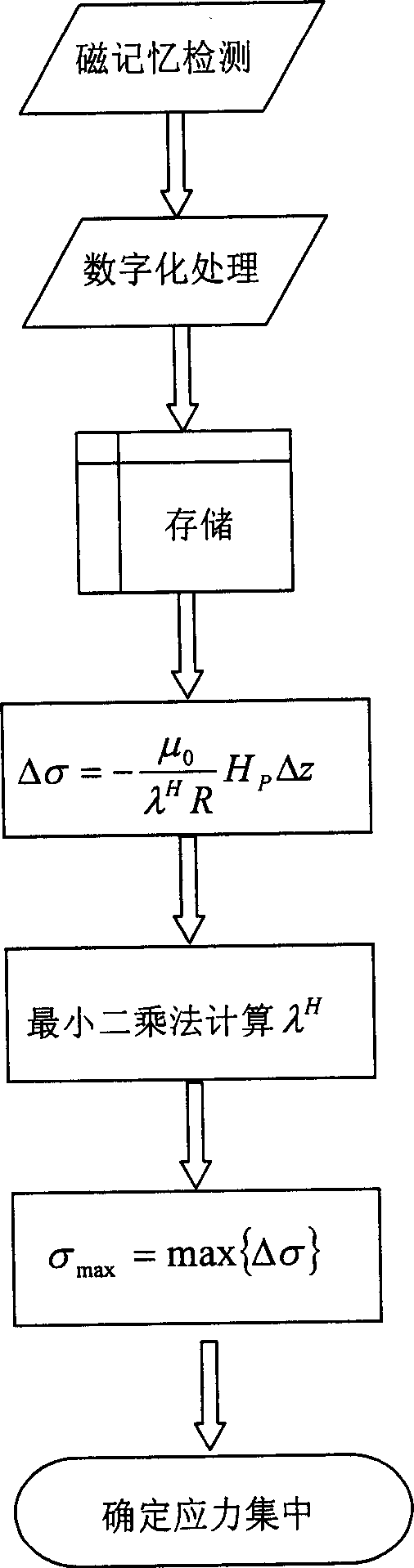

Method used

Image

Examples

Embodiment Construction

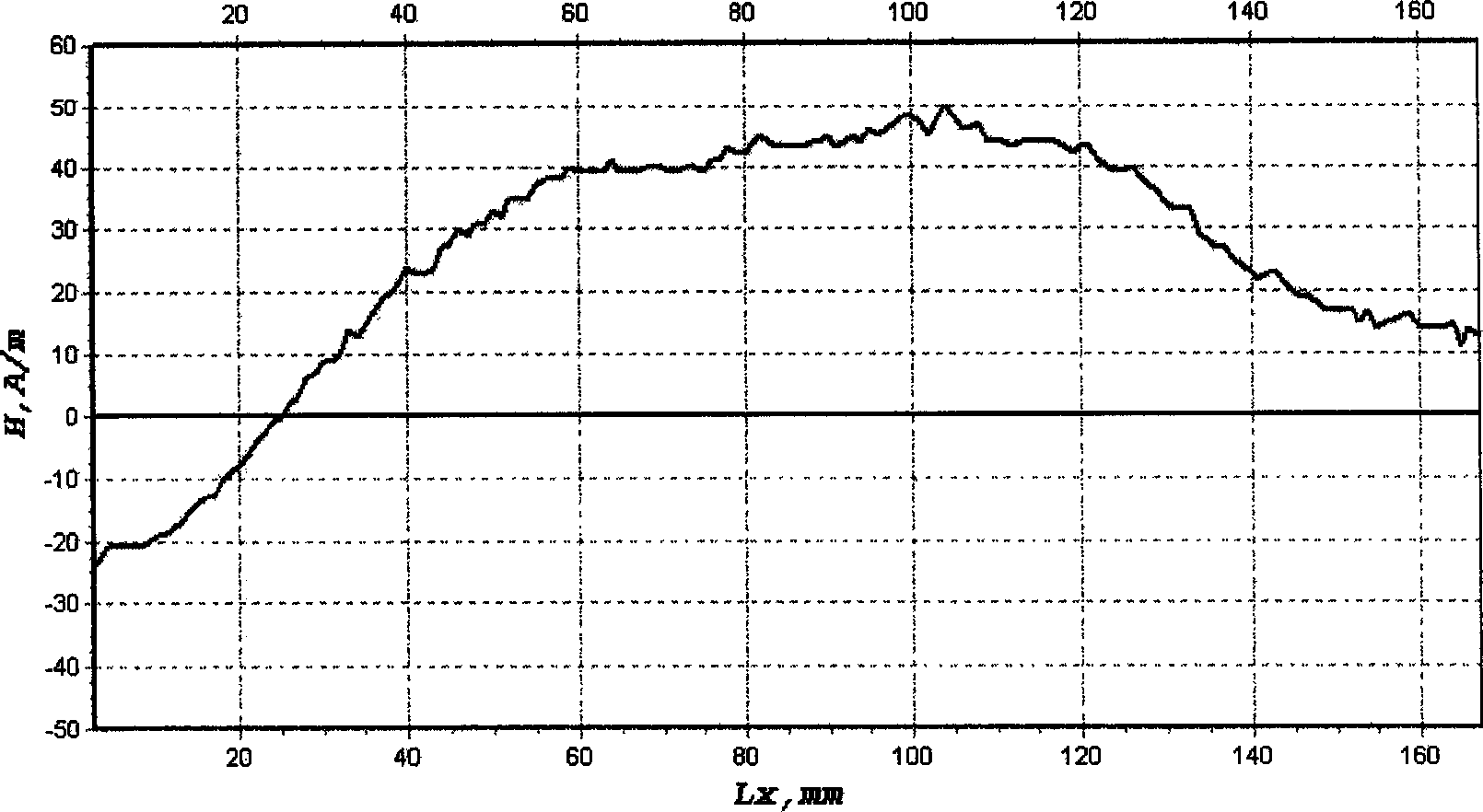

[0031] The TSC-1M-4 metal magnetic memory detector is used to detect the welded joints of the X65 pipeline steel welded steel pipe on site. The geometric size of the steel pipe is Φ468×8mm. After nine welds containing welding cracks are detected, calculation is performed according to the calculation flow chart of the present invention, and the stress concentration value at the tip of each welding crack is obtained, as shown in Table 1. In order to compare with the calculated results, the stress concentration at the crack tip was measured by the small hole method, and the measured values are shown in Table 1.

[0032] serial number

[0033] It can be seen from the data in the table that the error between the measured value and the calculated value is less than 15%, which shows that the non-destructive determination of the stress concentration at the tip of the welding crack by the present invention is accurate and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com