Battery safety assessment method

A safety and battery technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve problems such as safety accidents, battery safety degradation, and battery destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

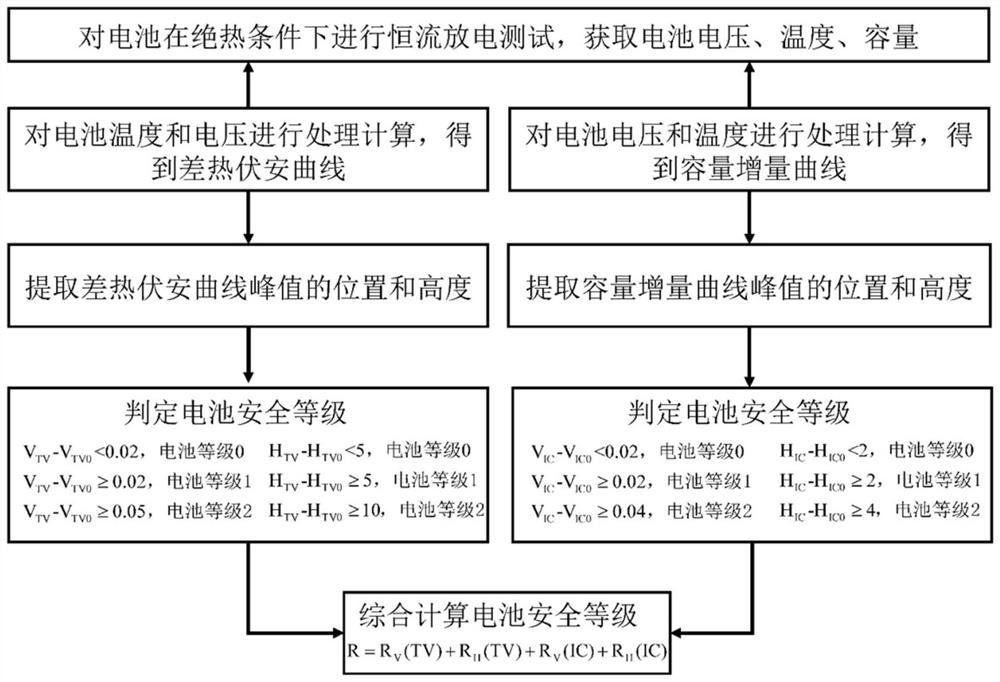

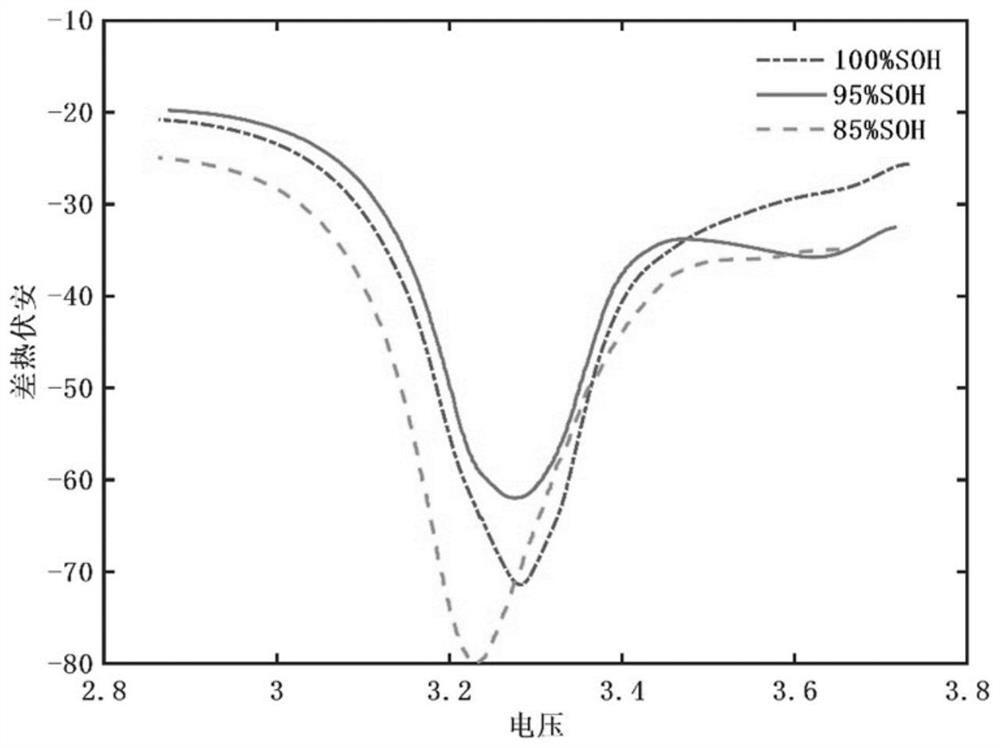

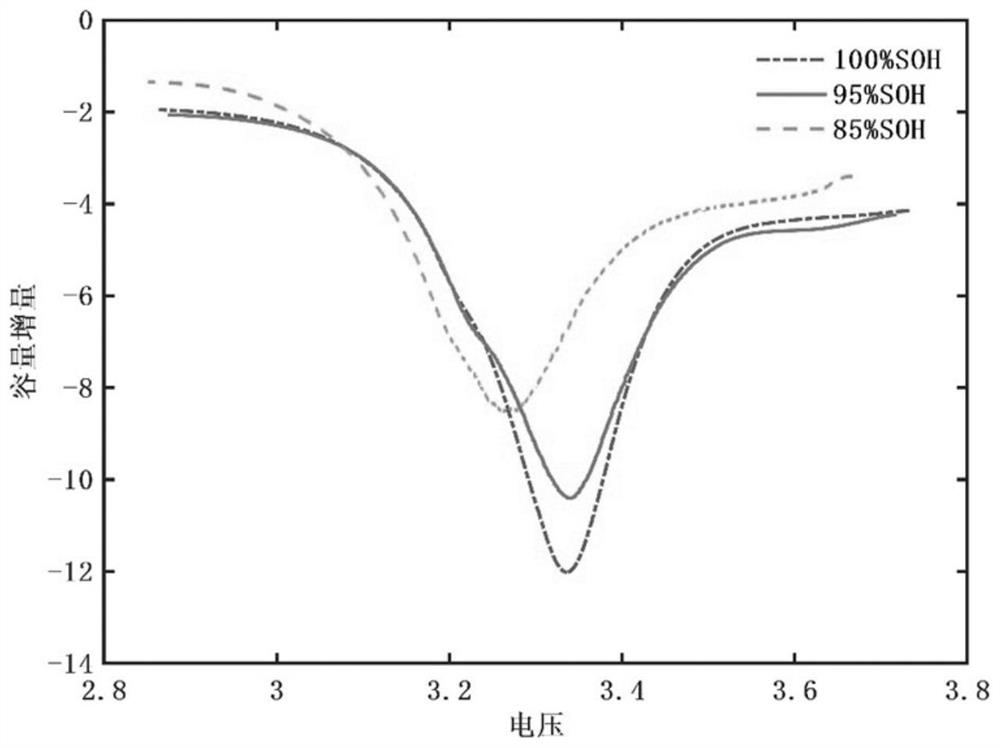

[0042] like figure 1 As shown, the present invention provides a non-destructive battery safety evaluation method. In this example, the test objects are batteries in different aging states after cycling at 60°C. The cycle aging method is 0.5C constant current and constant voltage charging. For the discharge method, the batteries are aged to 100% SOH, 95% SOH, and 85% SOH respectively, and the constant current discharge test is carried out under adiabatic conditions. The constant current discharge test is carried out in an adiabatic accelerated calorimeter.

[0043] Through the battery test system, the test battery in the fully charged state is subjected to a 1 / 3C constant current discharge test under adiabatic conditions to obtain the voltage, temperature and capacity data during the entire discharge process, and the battery's voltage and temperature are calculated and processed to obtain the battery. Differential thermal voltammetry curves, such as figure 2 shown. Then obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com