Filtering material made from waste mud and its prodn. method

A sludge and filter material technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as sludge not being effectively utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

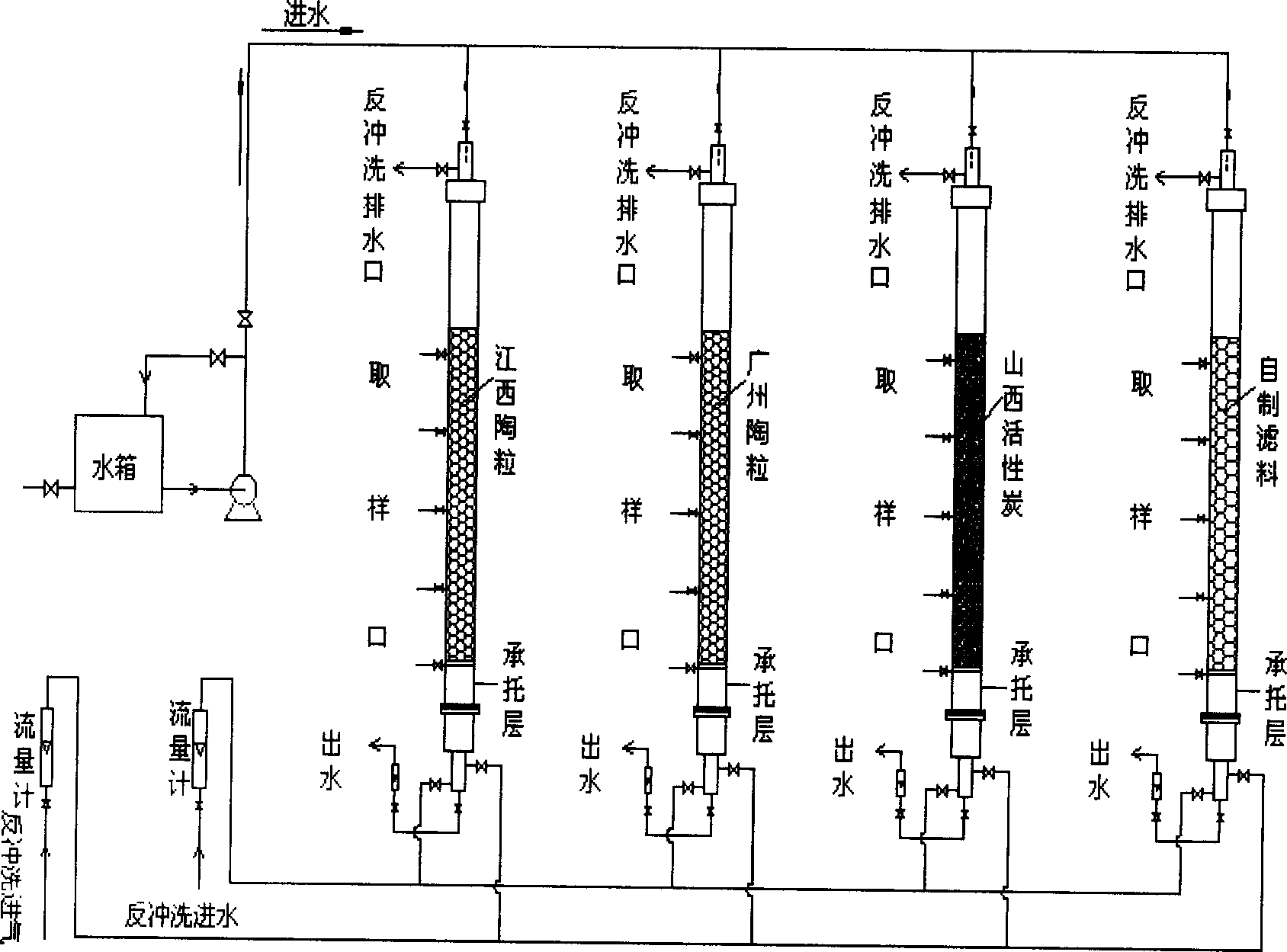

Method used

Image

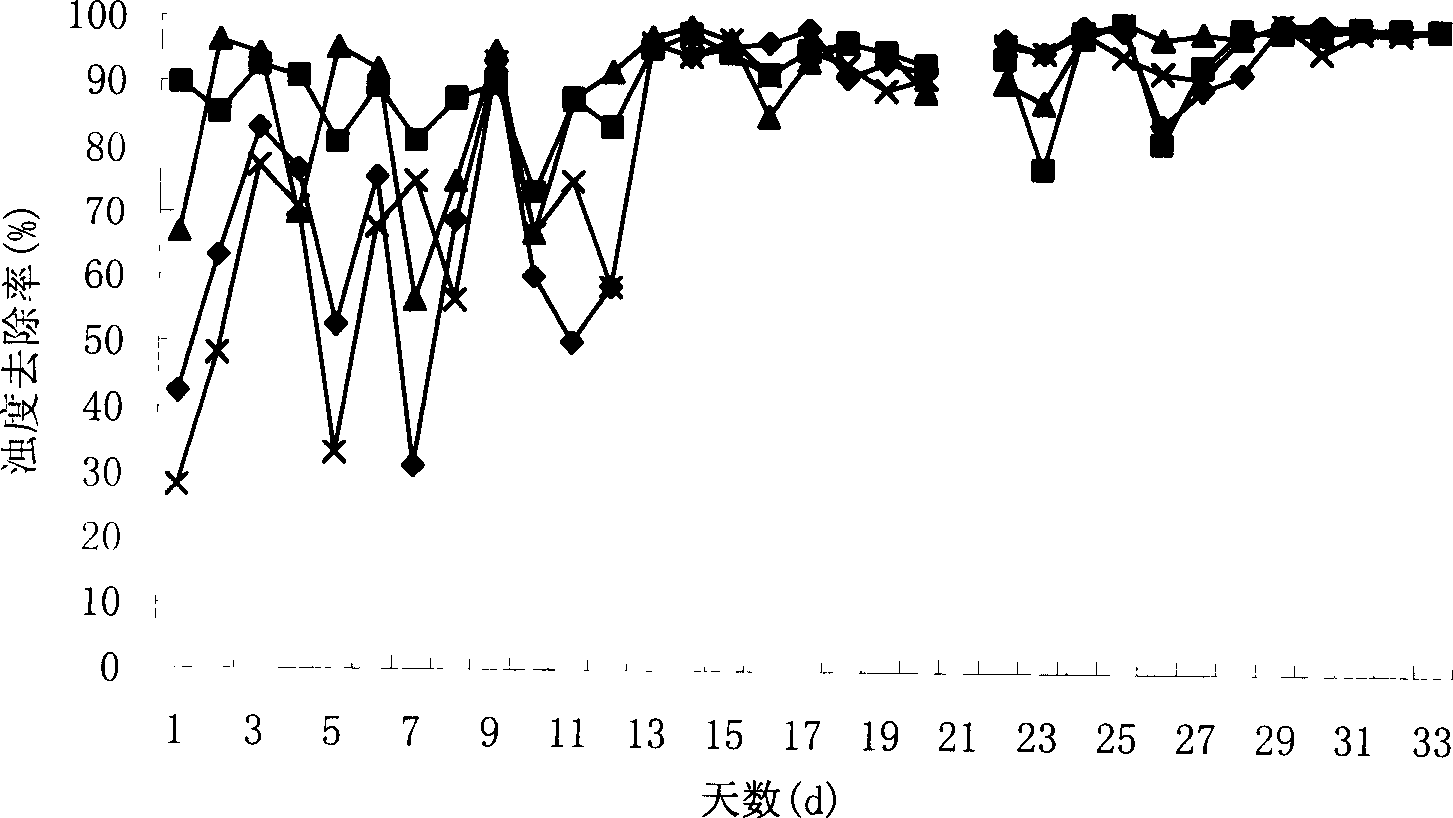

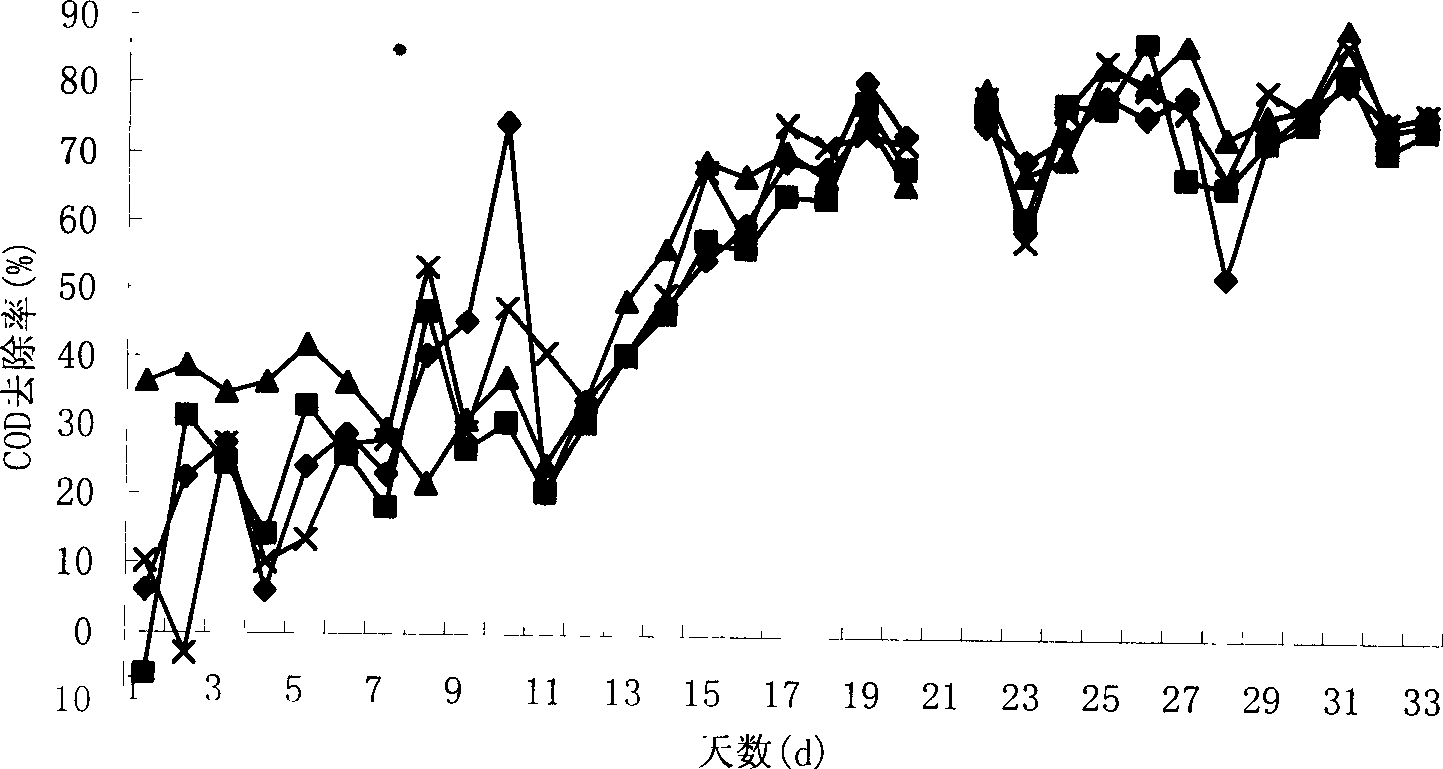

Examples

specific Embodiment approach 1

[0007] Specific embodiment 1: The filter material of this embodiment is prepared from the raw materials of the following components: sludge, clay, binder, and the addition amount of each raw material is respectively: clay accounts for 80~150% of the dry sludge mass %, the binder accounts for 5-30% of the dry sludge mass; its preparation method is that after mixing the raw materials according to the stated ratio, the temperature is raised to 700-1100° C., and then fired for 10-30 minutes.

specific Embodiment approach 2

[0008] Specific embodiment two: the addition amount of each raw material in this embodiment is respectively: clay accounts for 100% of dry sludge quality, binder accounts for 10% of dry sludge quality; Fired at 900°C for 25 minutes.

specific Embodiment approach 3

[0009] Specific embodiment three: the addition amount of each raw material in this embodiment is respectively: clay accounts for 130% of dry sludge quality, binder accounts for 25% of dry sludge quality; Fired at 1100°C for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| burnout rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com