Automatic transmission

By combining a planetary gear train and a parallel shaft gear train in a parallel-shaft automatic transmission, clutch and brake control are optimized, the balance problem between fuel consumption and compactness is solved, and efficient fuel consumption and transmission efficiency are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

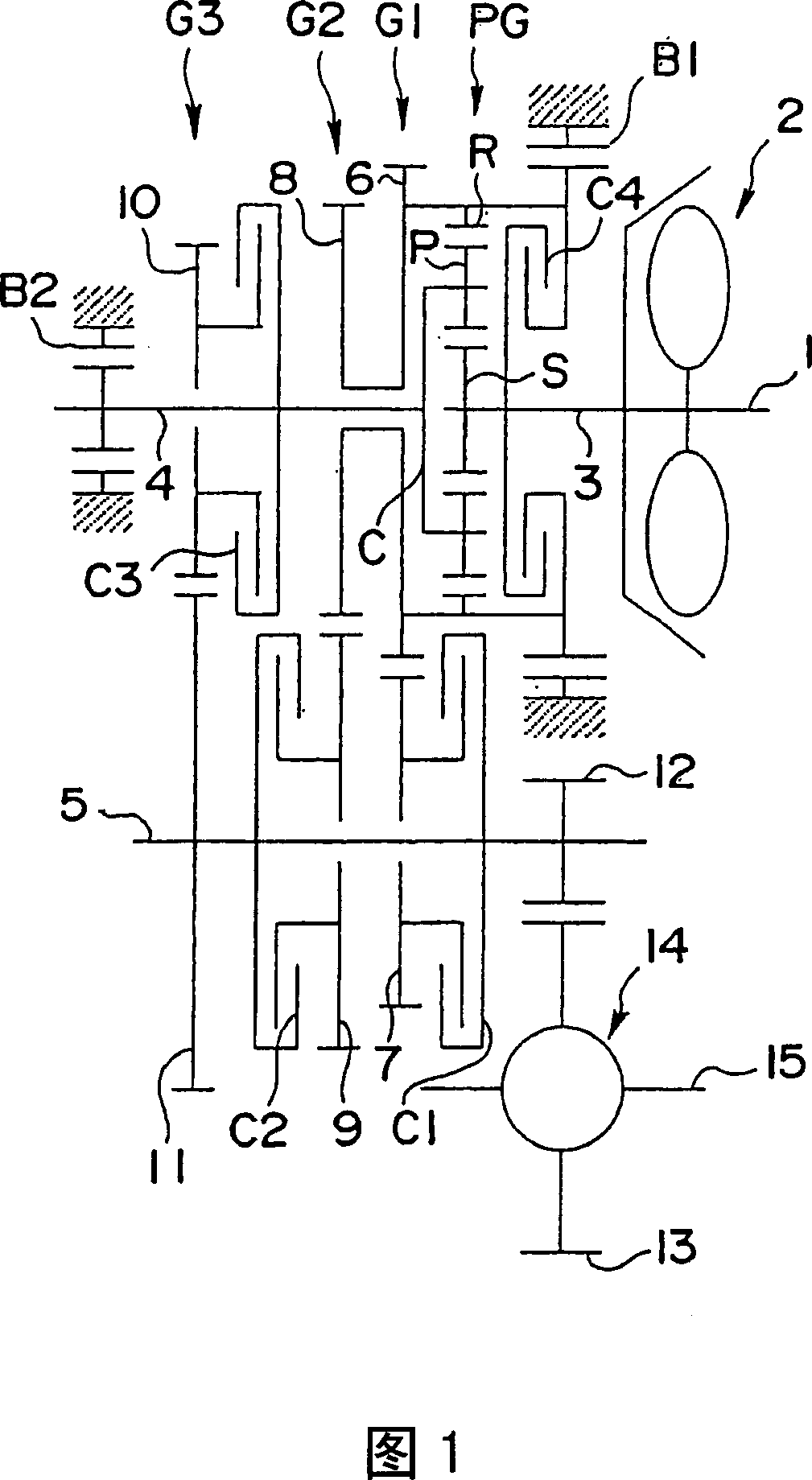

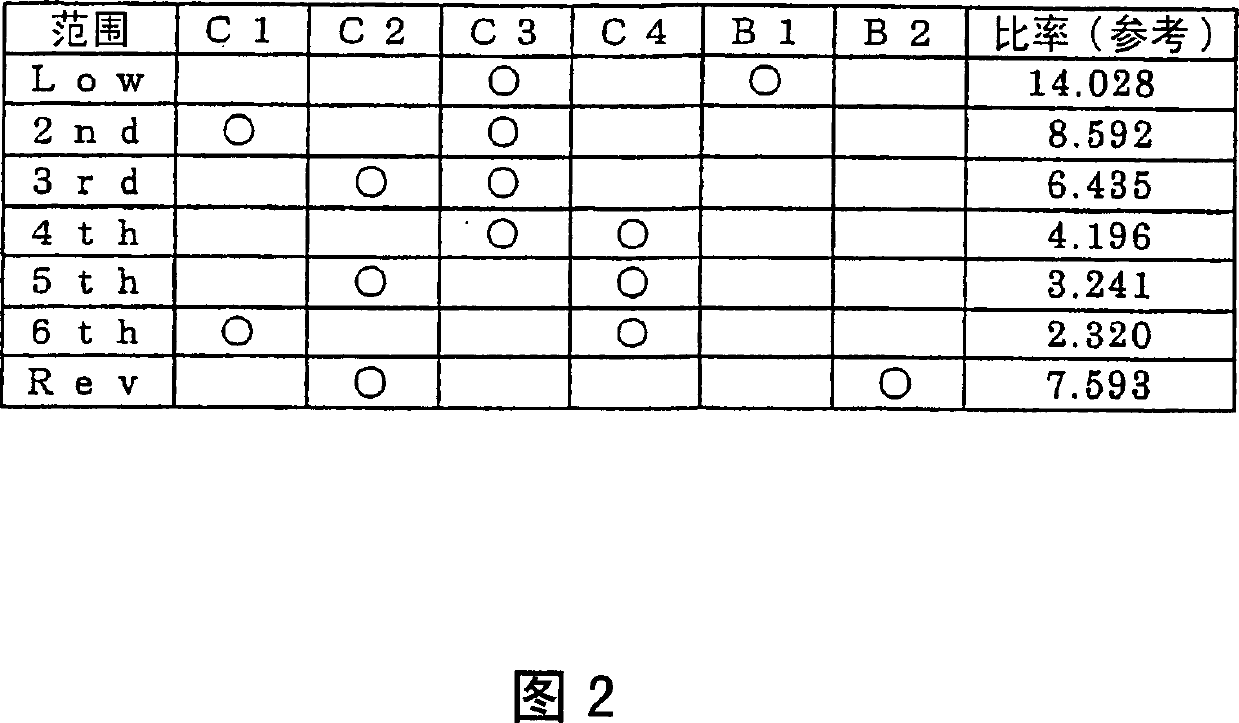

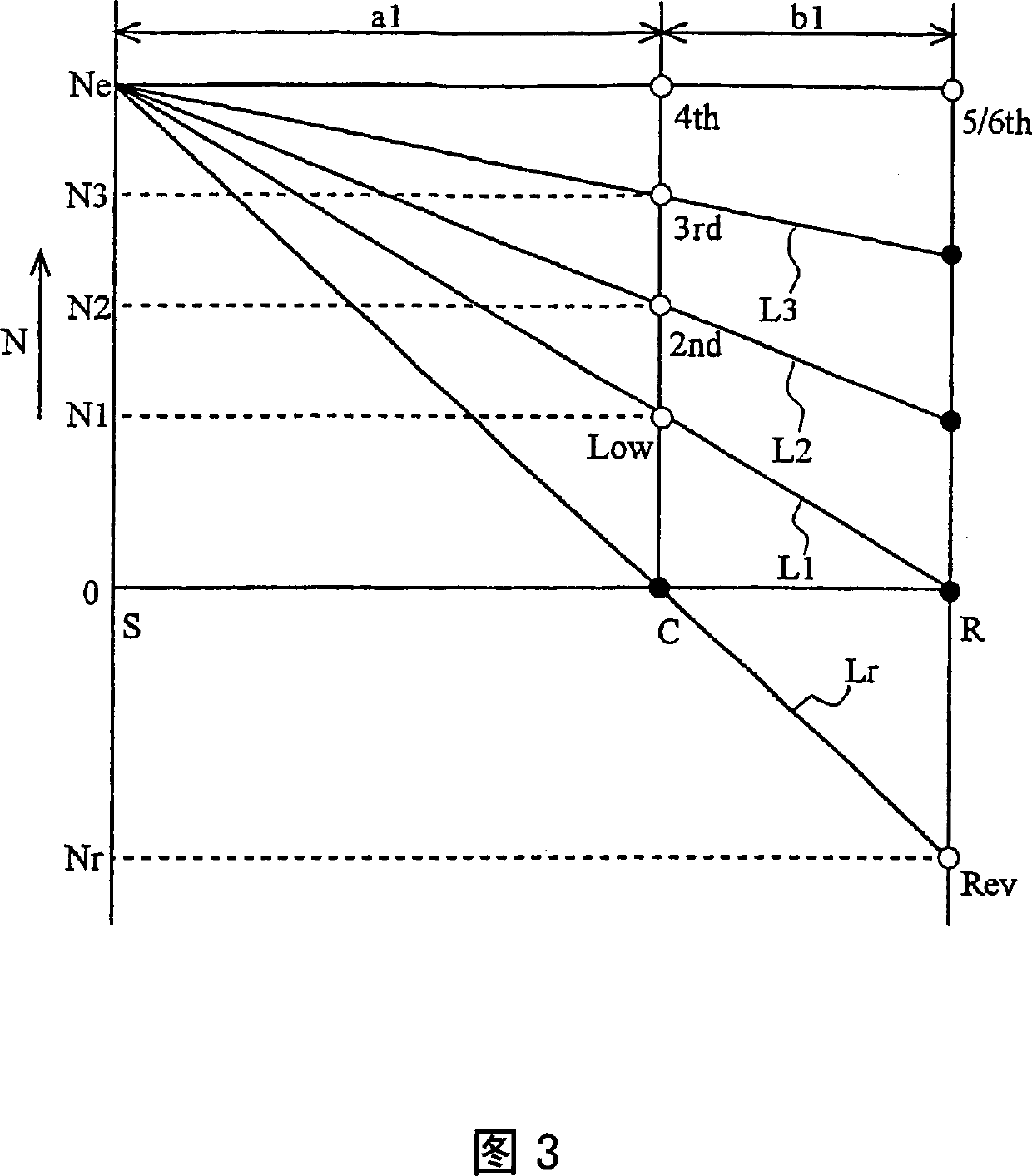

[0026] Preferred embodiments of the present invention will be described below with reference to the drawings. As shown in FIG. 1 , the automatic transmission of the present invention has the following structure: a planetary gear train PG; a countershaft 5 arranged in parallel with the rotation axis of the planetary gear train PG (the first main shaft 3 and the second main shaft 4 described later); Three sets of gear trains G1-G3 and six friction engagement mechanisms (brakes B1, B2 and clutches C1-C4).

[0027] The planetary gear train PG is composed of the following elements: a sun gear S connected to the first main shaft 3 located at its rotation center as the input shaft of the transmission; a pinion P meshing with the sun gear and revolving around itself while rotating; a holding pinion P is free to rotate and revolves around the axis of the sun gear S at the same number of revolutions as the pinion; it has internal teeth that mesh with the pinion P and can rotate around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com