Pressure resisting Silicon rubber hose and its mfg. method

A manufacturing method and silicone rubber technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy insertion of fiber threads into the inner rubber layer, lack of strength, inner rubber layer pollution, etc., to ensure the braiding quality , Increase the tension of the outlet line, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

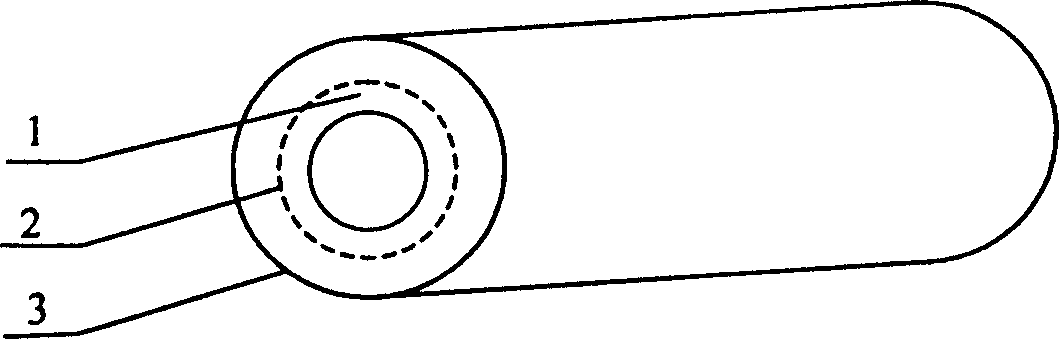

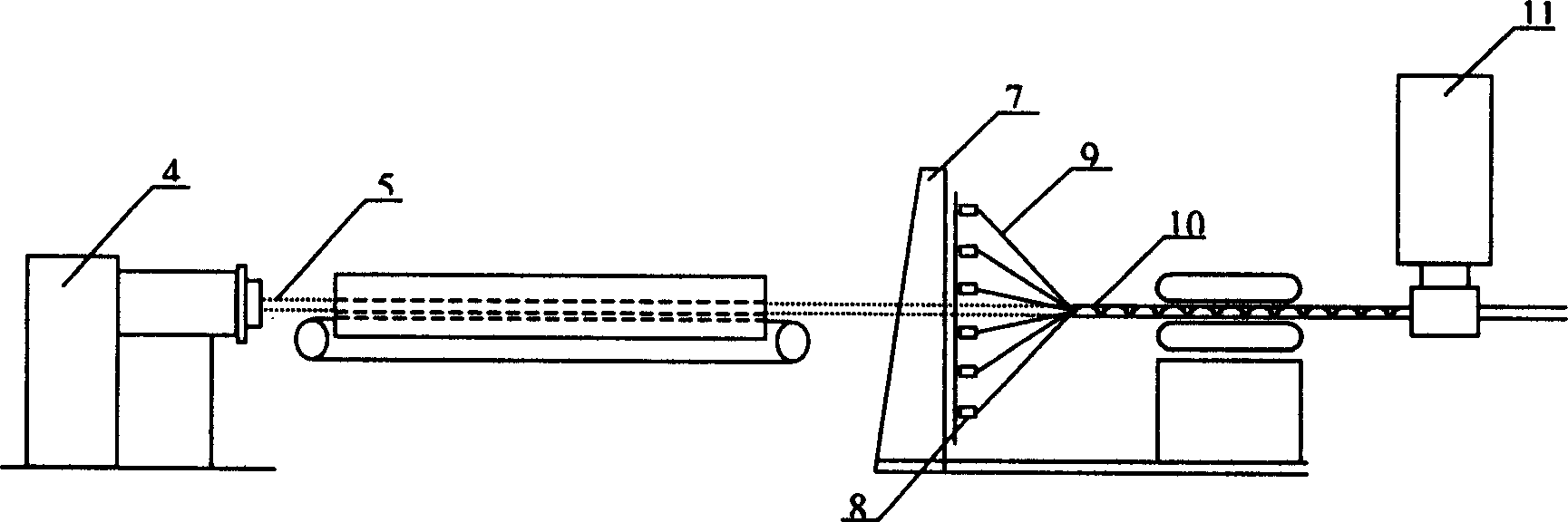

[0021] see figure 1 and figure 2 , taking the pressure-resistant silicone rubber tube for blood transport used in the production of biological preparations as an example, this type of rubber tube requires a working pressure of 5kg / mm 2 , burst strength ≥ 15kg / mm 2 Above, the temperature resistance is required to be above 150°C, and there is no pollution to the blood. The use of pure silicone rubber hose cannot meet the above working pressure requirements, and the use of cloth hose is short in length and connected by multiple pieces, which is cumbersome to operate and easy to leak; Use food-grade natural rubber braided hose, which is easy to age and has potential pollution.

[0022] For this reason, adopt the pressure-resistant silicon rubber hose of the present invention and manufacturing method thereof, inner rubber layer [1] is main material with silicon rubber, mixes with 2,4-dichlorobenzoyl peroxide as vulcanizing agent, The inner diameter is Φ12mm, and the wall thickn...

Embodiment 2

[0024] A kind of high-pressure steam rubber hose used in the food industry, which requires a pressure resistance of 6kg / mm 2 , burst strength ≥ 17kg / mm 2 Above, the temperature resistance is required to be above 140°C. The original ethylene-propylene rubber braided hose is required to be replaced by a silicone rubber hose because it will cause some unpleasant odor pollution to the finished product.

[0025] The inner rubber layer [1] has an inner diameter of 10mm and a wall thickness of 2mm. The inner rubber layer is mixed with bis-2,5[2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane ] as a vulcanizing agent, the extruded inner tube blank [5] was coiled in a water-bath vulcanization tank, and heated directly by steam at 145°C for 8 minutes to complete the pre-vulcanization treatment, and the rest were the same as in Example 1. The obtained product, Bursting strength up to 20kg / cm 2 , The product quality is stable, for users to use, and solves the problem of special odor pollutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com