Shaft mounted brake disk of SiC granule enhanced aluminium based composite material

A particle-reinforced aluminum and composite material technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of weakened heat dissipation effect and large wind resistance loss, etc., to eliminate internal casting defects, increase wind resistance loss, and improve ventilation. The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with accompanying drawing:

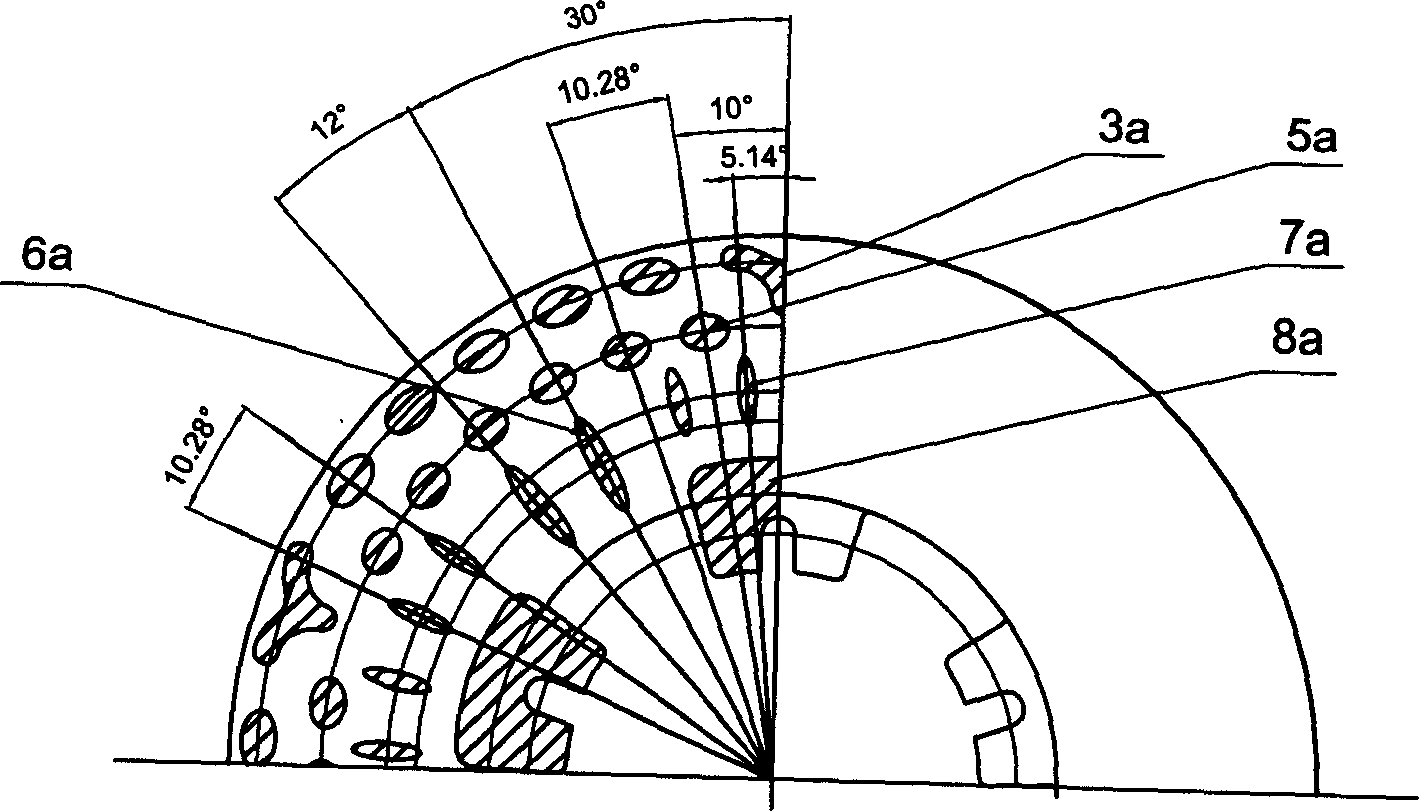

[0020] A shaft-mounted SiC particle reinforced aluminum matrix composite brake disc Figure 1 , including the upper and lower friction disc surfaces 1, 2, heat dissipation ribs 3, 4, 5, 6, 7, 8 and flange 9.

[0021] The thickness of the upper and lower friction discs 1 and 2 is 32mm, the outer diameter is Φ640mm, and the inner diameter is Φ334mm;

[0022] There are 6 types of cooling ribs, T-shaped cooling ribs 3, columnar cooling ribs 4, columnar cooling ribs 5, plate-shaped cooling ribs 6, plate-shaped cooling ribs 7 and arc-shaped cooling ribs 8, all of which are 46mm in height:

[0023] Five T-shaped cooling ribs 3 are evenly distributed on the outer ring of the brake disc. The central symmetry line of the T-shaped cooling ribs 3 is radially distributed, and the centroid of the section is located on a circle of Φ600mm. The cross-sectional profile of the T-shaped cooling rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com