Flat tube for aluminium heat exchanger

A heat exchanger and flat tube technology, applied in the field of aluminum flat tubes, can solve problems such as corrosion of contact parts, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described as follows with reference to the accompanying drawings:

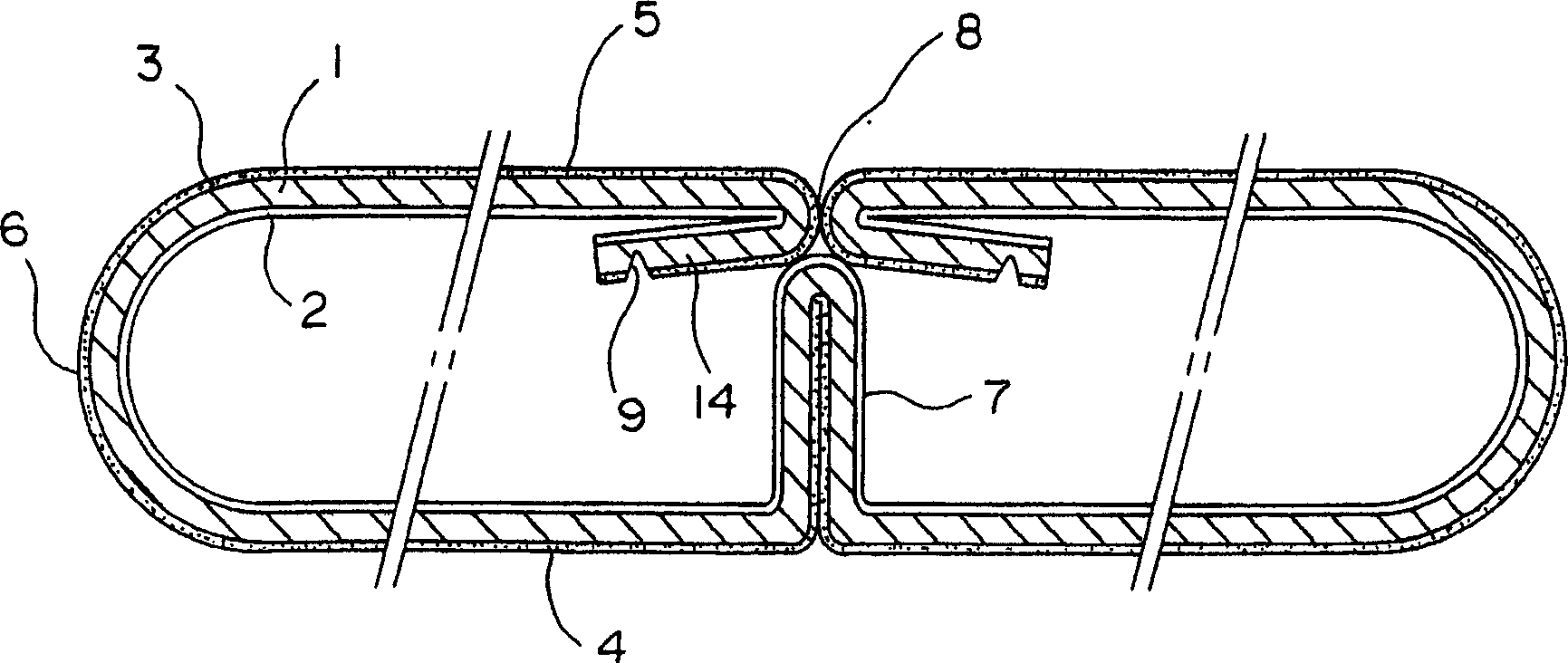

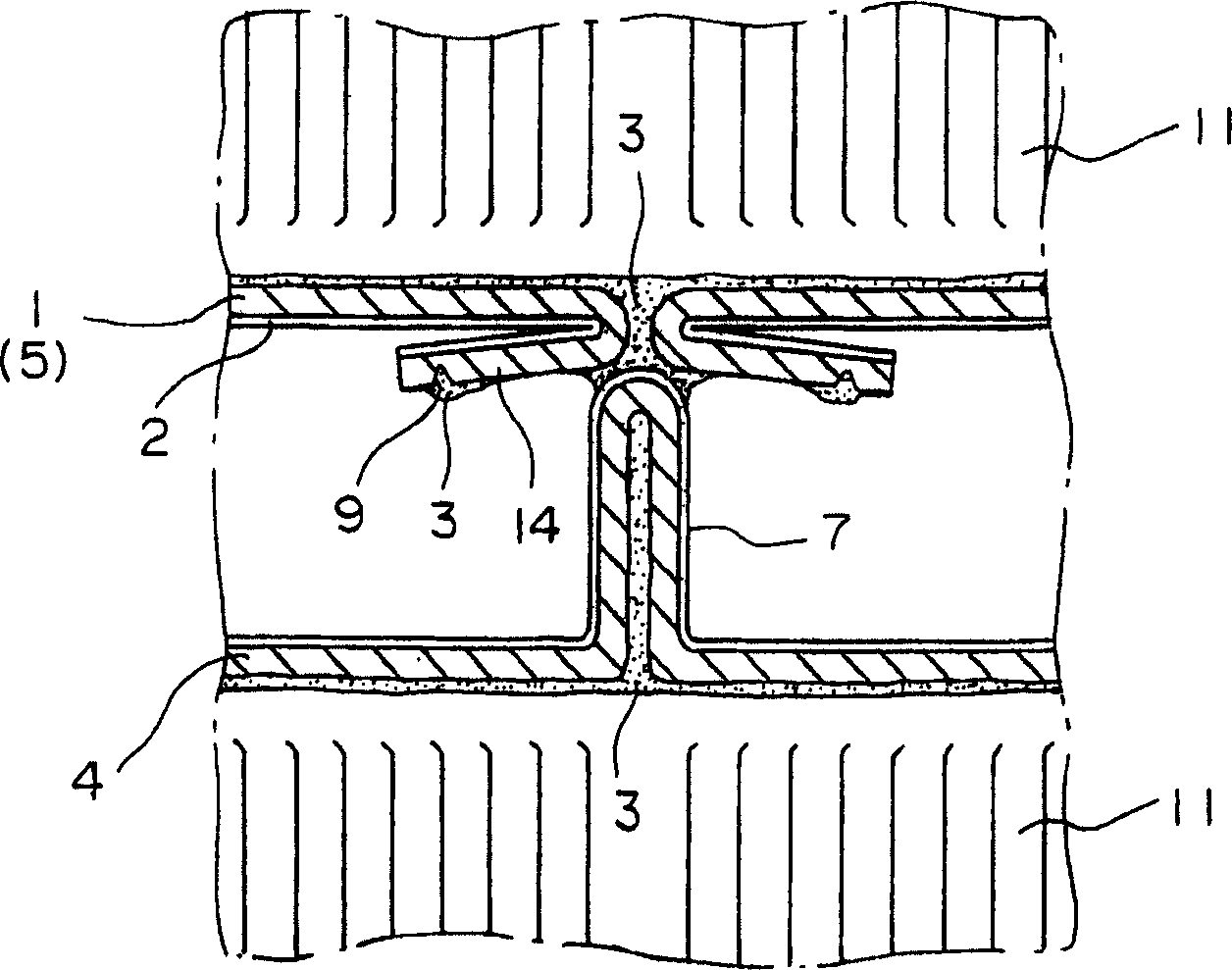

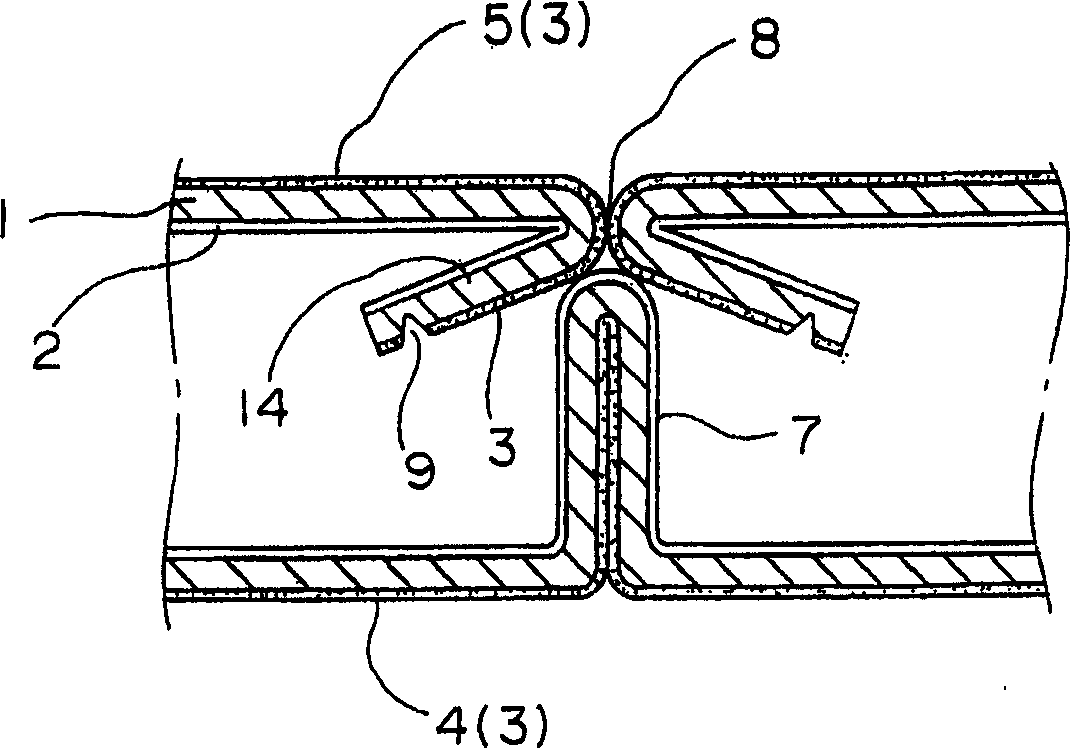

[0033] figure 1 A cross-sectional view of a flat tube according to a first embodiment of the invention is shown, given the state before welding. figure 2 A cross-sectional view of the main part of the flat tube is shown, giving the state after welding.

[0034] The first embodiment presents a flat tube formed by bending in its width direction an aluminum strip material made of brazing filler metal 3 coated with an aluminum alloy on its outer surface and It consists of an aluminum core material 1 coated with a sacrificial anode material 2 made of aluminum alloy on its inner surface.

[0035]The strip-shaped material is bent in the width direction so that the first flat surface 4 and the second flat surface 5 face each other in parallel, while the first flat surface 4 and the second flat surface are connected in the width direction by a pair of bent portions 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com