Double corrosion prevention method for ocean structure

A marine structure, dual technology, applied in underwater structures, infrastructure engineering, construction, etc., can solve the problem that the anti-corrosion method cannot achieve the anti-corrosion effect well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 6 double anti-corrosion methods for marine structures

[0057] The marine structure 6 double anti-corrosion method includes the following steps:

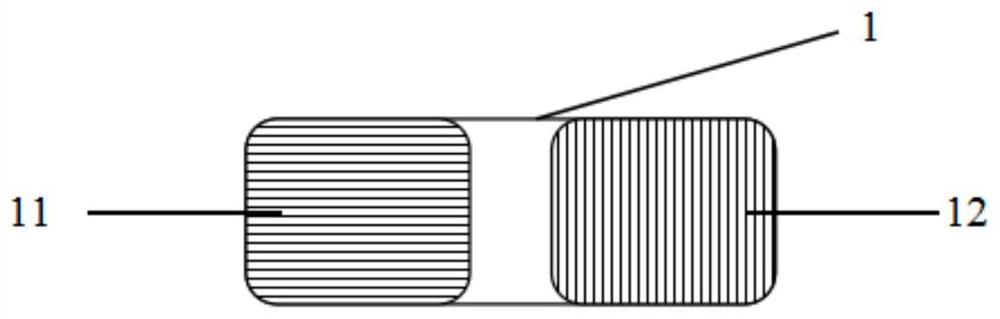

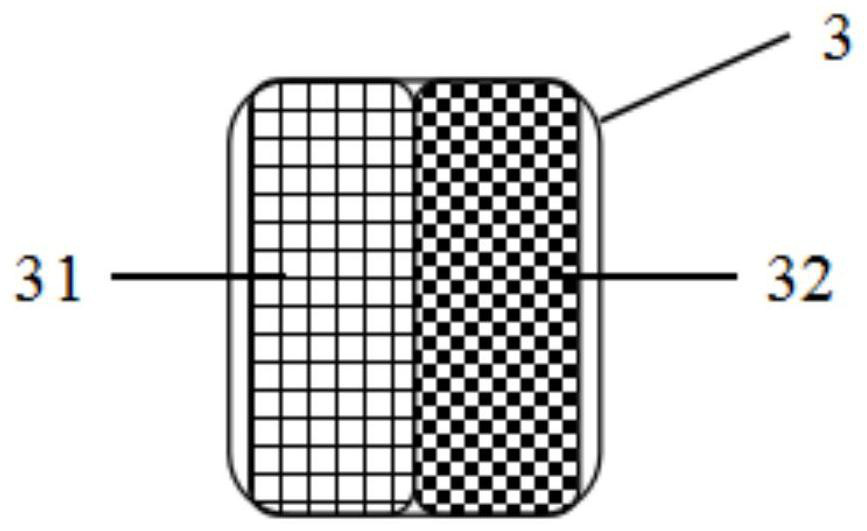

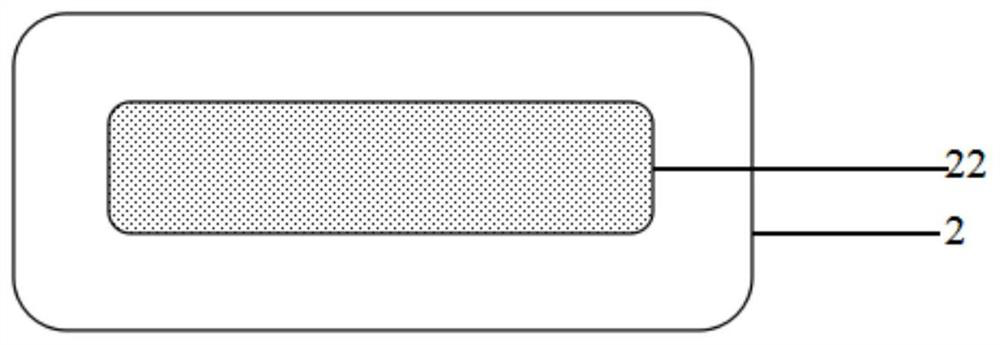

[0058] Provide a double anti-corrosion system, the double anti-corrosion system includes: self-generating unit 1, current conversion unit 4, working electrode 5 and counter electrode 7,

[0059] The self-generating unit 1 is used to collect marine mechanical energy and converted into AC power, and the current conversion unit 4 is used to convert the AC power into DC power;

[0060] The negative terminal of the output voltage of the current conversion unit 4 is connected to the working electrode 5, the working electrode 5 is connected to the marine structure 6, the positive terminal of the output voltage of the current conversion unit 4 is connected to the counter electrode 7, and the counter electrode 7 is submerged in seawater , forming a protective circuit to protect the marine structure 6; wherein, the self-generating uni...

Embodiment 2

[0062] 6 double anti-corrosion methods for marine structures

[0063] The marine structure 6 double anti-corrosion method includes the following steps:

[0064] Provide a double anti-corrosion system, the double anti-corrosion system includes: self-generating unit 1, current conversion unit 4, working electrode 5 and counter electrode 7,

[0065] The self-generating unit 1 is used to collect marine mechanical energy and converted into AC power, and the current conversion unit 4 is used to convert the AC power into DC power;

[0066] The negative terminal of the output voltage of the current conversion unit 4 is connected to the working electrode 5, the working electrode 5 is connected to the marine structure 6, the positive terminal of the output voltage of the current conversion unit 4 is connected to the counter electrode 7, and the counter electrode 7 is submerged in seawater In the process, a protection circuit is formed to protect marine structures 6;

[0067] Wherein, ...

Embodiment 3

[0069] 6 double anti-corrosion methods for marine structures

[0070] The marine structure 6 double anti-corrosion method includes the following steps:

[0071] Provide a double anti-corrosion system, the double anti-corrosion system includes: self-generating unit 1, current conversion unit 4, working electrode 5 and counter electrode 7,

[0072] The self-generating unit 1 is used to collect marine mechanical energy and converted into AC power, and the current conversion unit 4 is used to convert the AC power into DC power;

[0073] The negative terminal of the output voltage of the current conversion unit 4 is connected to the working electrode 5, the working electrode 5 is connected to the marine structure 6, the positive terminal of the output voltage of the current conversion unit 4 is connected to the counter electrode 7, and the counter electrode 7 is submerged in seawater , forming a protective circuit to protect the marine structure 6; wherein, the self-generating unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com