LED integrated tube core

A die-and-single technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of disproportion, expensive fluorescent materials, easy attenuation, etc., to achieve low current loss, good white light effect, and simplified process and design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

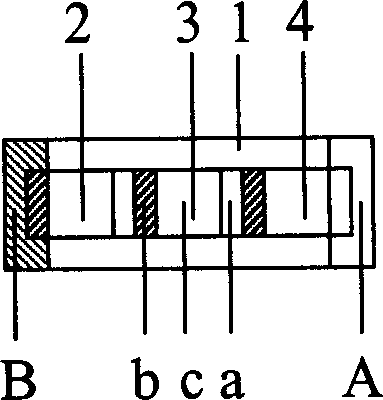

[0023] Embodiment 2. A multi-level series-connected parallel LED integrated die, combined with Image 6 , compared with Embodiment 1, the difference in structure is that each stage in series is composed of two single dies connected in parallel. Of course, some stages may also be configured in a parallel structure, while some stages still use the structure of a single die.

Embodiment 3

[0024] Embodiment 3. A multi-level series-head-to-tail parallel LED integrated die, combined with Figure 7 , which is formed by parallel connection of two rows of in-line multi-level series dies having the same structure as that of the first embodiment.

Embodiment 4

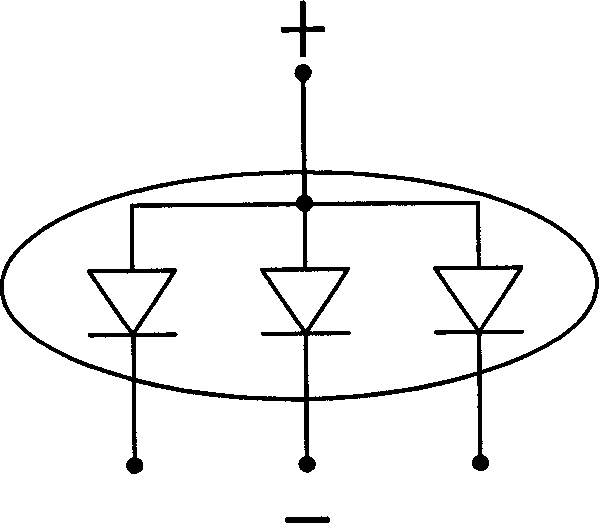

[0025] Embodiment 4, a white light three-stage series-connected LED integrated die has the same structure as Embodiment 1, and the three light-emitting diode dies 2, 3, and 4 integrated in series are red, green, and blue respectively. color.

[0026] The realization of the present invention can be arranged after the single LED tube core is produced, and several required single LED tube cores are integrated together in a multi-stage series structure to produce an equivalent LED tube core with a higher V F The LED integrated tube core; also can advance technology to single LED tube core production process, for example for the LED of single species or for the LED that adopts same semiconductor basic material, the realization of the present invention can be in doping, mask etc. It starts in the early stage of the process, so that the production can simplify the subsequent process and cost. In the above-mentioned embodiments, the number of integrated dies can be determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com