Dye component and its use

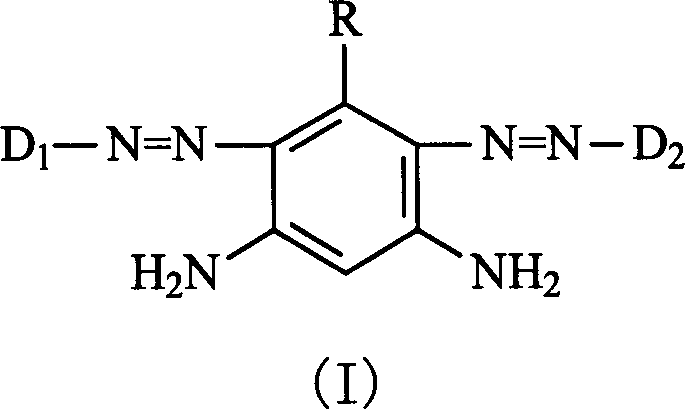

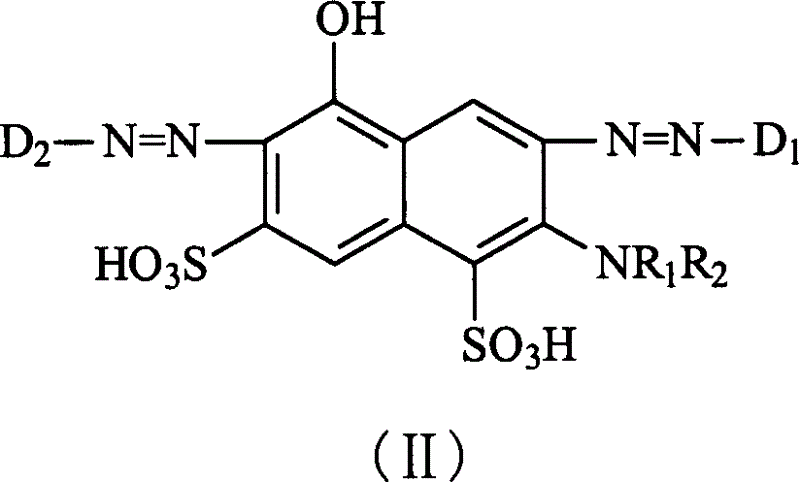

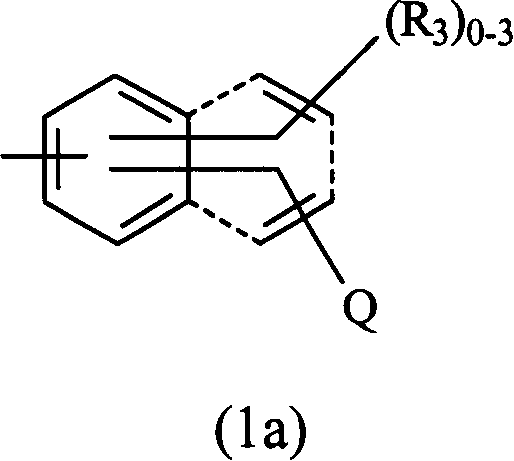

一种组成物、染料的技术,应用在有机染料、染色法、纺织品和造纸等方向,能够解决无法克服染深性不佳及洗净性不良、难以满足等问题,达到低日光坚牢度、低尼龙污染、优异染深性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0108] 115.6 parts of 1-aminobenzene-2-sulfonic acid-4-β-sulfatoethanesulfonyl (1-aminobenzene-2-sulfonic acid-4-β-sulfatoethylsulfone) were dissolved and dispersed in 1000 parts of ice water, and then Add 80 parts of 32% HCl aqueous solution to it and stir thoroughly, then add 27 parts of sodium nitrite aqueous solution, and then continue stirring at 0 to 5° C. until the diazotization is completed. Next, 48.7 parts of 3,5-diaminobenzoic acid powder was added, and the reaction liquid mixture was stirred until the coupling reaction was completed. Finally, sodium chloride is added for salting out, and the mixture is taken out by filtration to obtain compound (P-1).

[0109]

[0110] Dissolve and disperse 16.8 parts of 1-aminobenzene-4-β-sulfatoethylsulfone (1-aminobenzene-4-β-sulfatoethylsulfone) in 150 parts of ice water, then add 8 parts of 32% HCl aqueous solution to fill it Then add 4.3 parts of sodium nitrite aqueous solution, and then continue stirring at 0 to 5°C unti...

preparation Embodiment 2

[0113] Dissolve 33.8 parts of 1-aminobenzene-4-β-sulfatoethylsulfonyl (1-aminobenzene-4-β-sulfatoethylsulfone) in 200 parts of ice water, then add 16 parts of 32% HCl aqueous solution to fill it Then add 8.7 parts of sodium nitrite aqueous solution, and then continue stirring at 0 to 5°C until the diazotization is completed. Then add 9.1 parts of 3,5-diaminobenzoic acid (3,5-diaminobenzoic acid) powder, and slowly adjust the pH value to 3.5 with sodium bicarbonate and stir the mixture at a temperature of 10-15°C until the coupling reaction is completed. Finally, add sodium chloride for salting out, and take out by filtration to obtain compound (3).

[0114]

preparation example 3

[0116] Dissolve 4.8 parts of 2-amino-4-((2,3-dibromopropionyl)amino)benzenesulfonic acid (2-amino-4-((2,3-dibrobopropionyl)amino)benzene sulfonic acid Disperse in 60 parts of ice water, then add 3.2 parts of 32% HCl aqueous solution to fully stir, then add 0.9 parts of sodium nitrite aqueous solution, and then continue stirring at room temperature until diazotization is completed. Then 6.1 parts of compound (P-1) was added, and the pH value was slowly adjusted to 5.0 with sodium carbonate, and the mixture was stirred at room temperature until the coupling reaction was completed. Finally, add sodium chloride for salting out, and take out by filtration to obtain compound (4).

[0117]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com