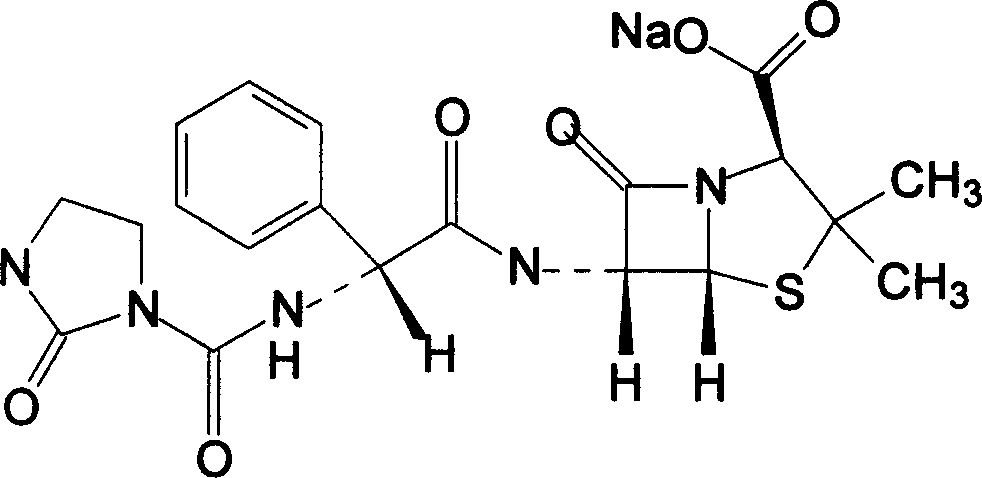

Crystalline azlocillin sodium and preparation thereof

A technology of azlocillin sodium and azlocillin acid, which is applied in organic chemistry and other fields, and can solve problems such as difficult solvent recovery, no practical value, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In the preparation method of crystalline azlocillin sodium of the present invention, the following are the preferred parameters:

[0019] The reaction temperature is controlled at 0~20℃, especially at 0~10℃; among them, the inorganic base is preferably sodium carbonate, sodium bicarbonate and sodium hydroxide;

[0020] The preferred organic solvents are acetone, ethanol, tetrahydrofuran, or a mixture thereof.

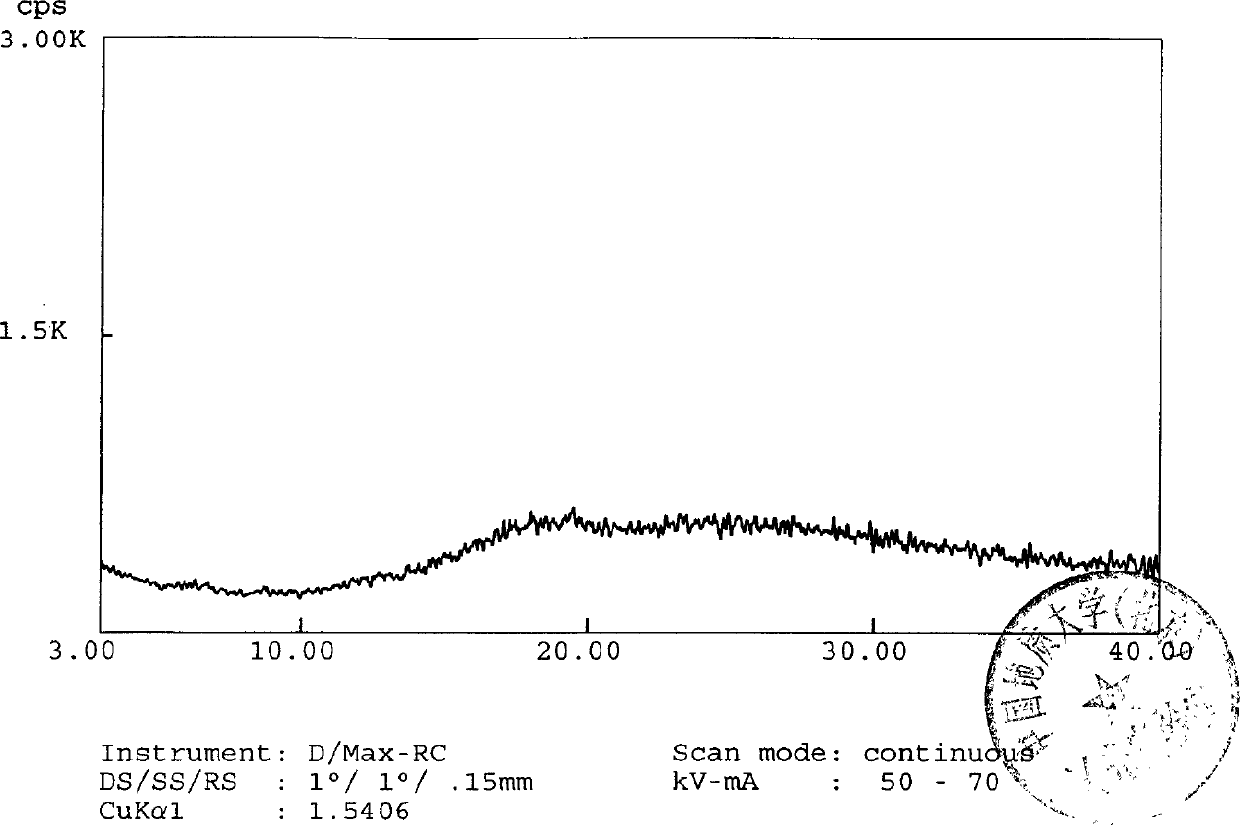

[0021] The crystalline azlocillin sodium prepared by the preferred method not only has a high content, good stability, but also has excellent fluidity, and is suitable for large-scale production of powder injections.

Embodiment 1

[0022] Example 1 Preparation of crystalline azlocillin sodium

[0023] Add 15ml of water and 5g of azlocillin acid to the reaction flask, stir and cool to 0~5℃, add 0.58g of anhydrous sodium carbonate, keep at 0~5℃ for 4 hours, filter, and add 250ml of acetone to the filtrate while stirring , Continue to stir for half an hour and let stand for 4 hours. Filter, wash twice with 30 ml of acetone, drain off, and dry under reduced pressure to obtain 4.2 g of crystalline azlocillin sodium. Purity: 99.13%

[0024] Measured with a DSC differential scanning calorimeter, the measured heat flow curve of azlocillin sodium shows that it has a decomposition point above 224°C.

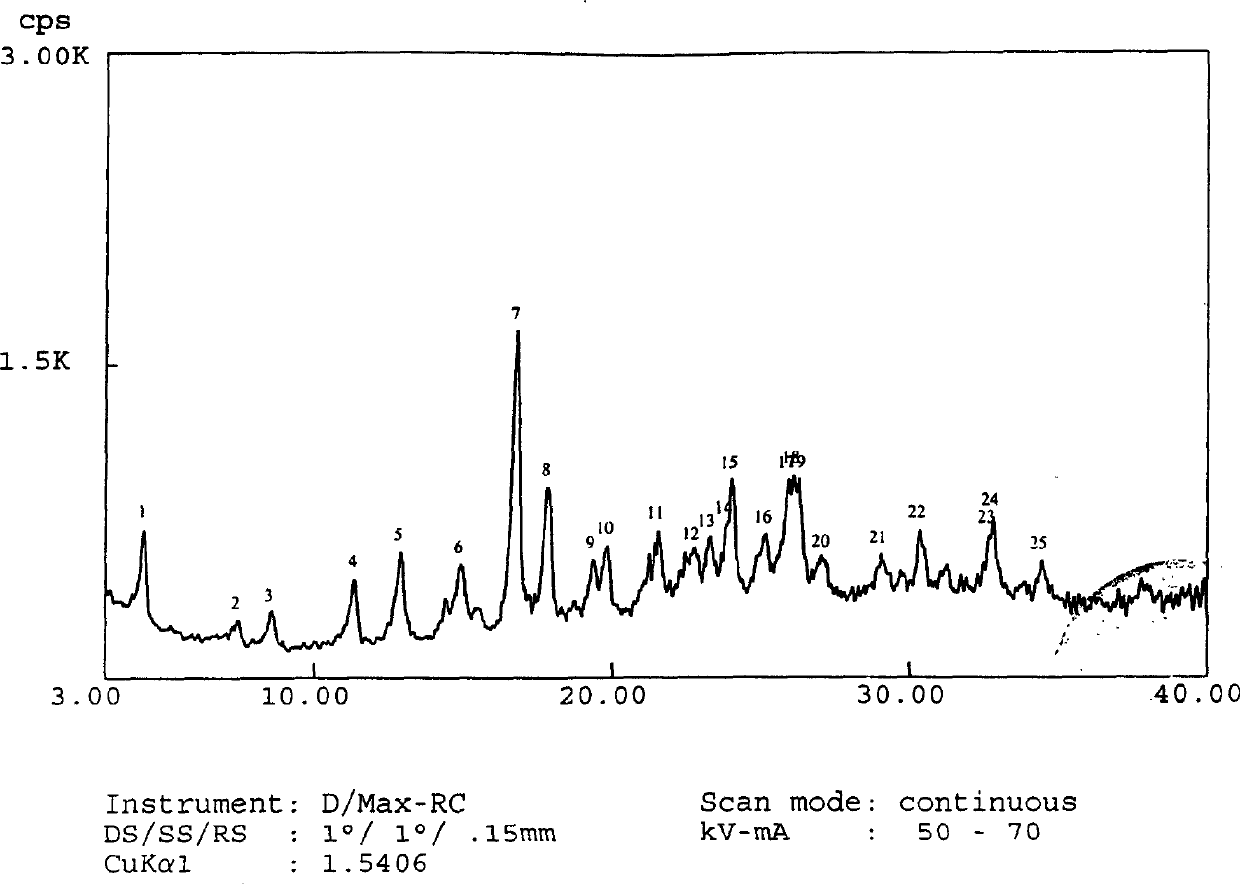

[0025] 2θ

Embodiment 2

[0026] Example 2 Preparation of crystalline azlocillin sodium

[0027] Add 15ml of water and 5g of azlocillin acid to the reaction flask, stir and cool to 0~5℃, add 0.95g of sodium bicarbonate, keep warm and stir for 5 hours, filter, add 300ml of absolute ethanol under stirring, continue stirring for half an hour, Let it stand for 4 hours, filter, wash twice with 20 ml of absolute ethanol, drain off, and dry under reduced pressure to obtain 3.6 g of crystalline azlocillin sodium. Purity: 98.82%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com