Dust collector for vacuum cleaner

A technology for dust collectors and vacuum cleaners, applied in suction filters and other directions, can solve the problems of filter damage, deterioration of suction performance, deterioration of air flow, etc., to prevent the reduction of suction force, improve suction performance, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

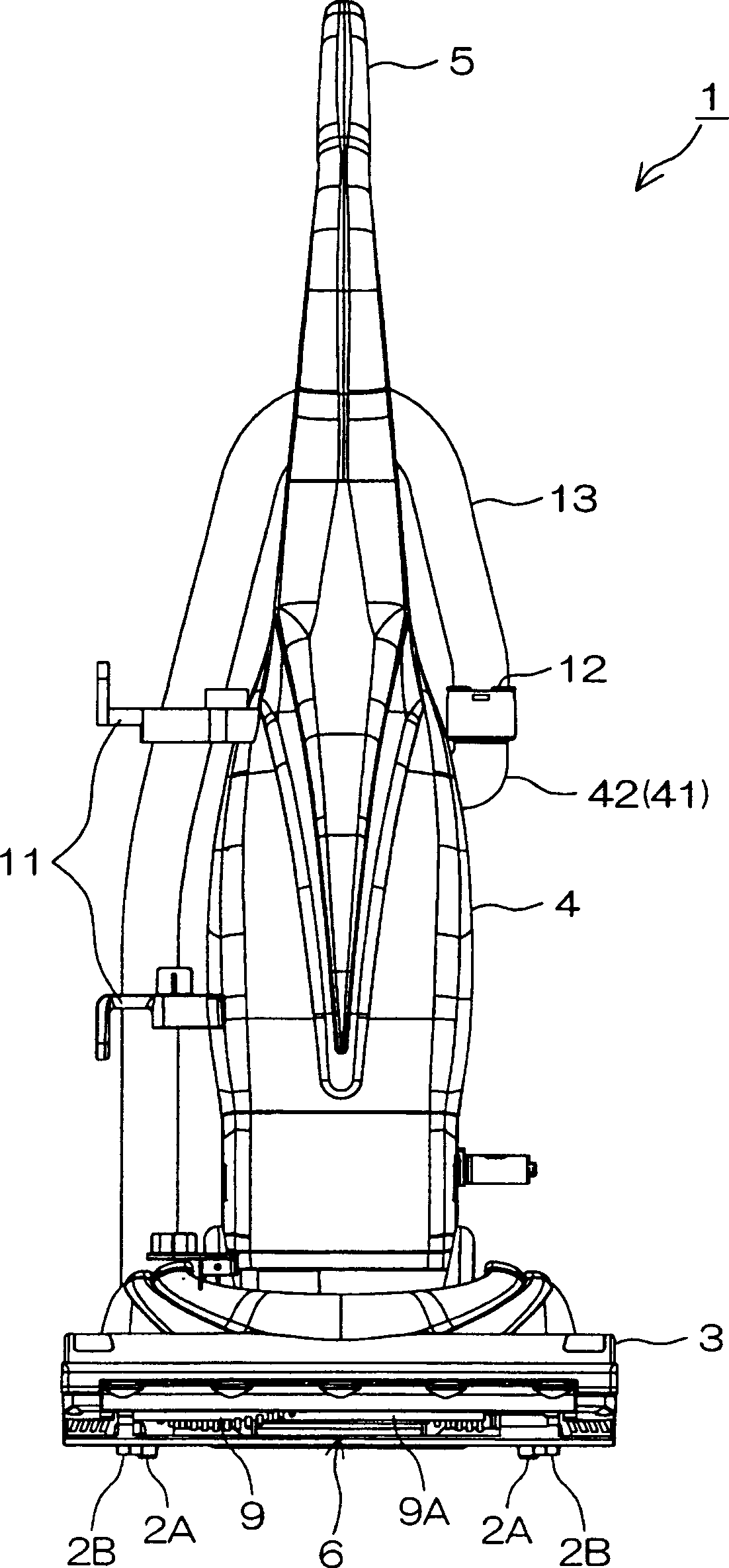

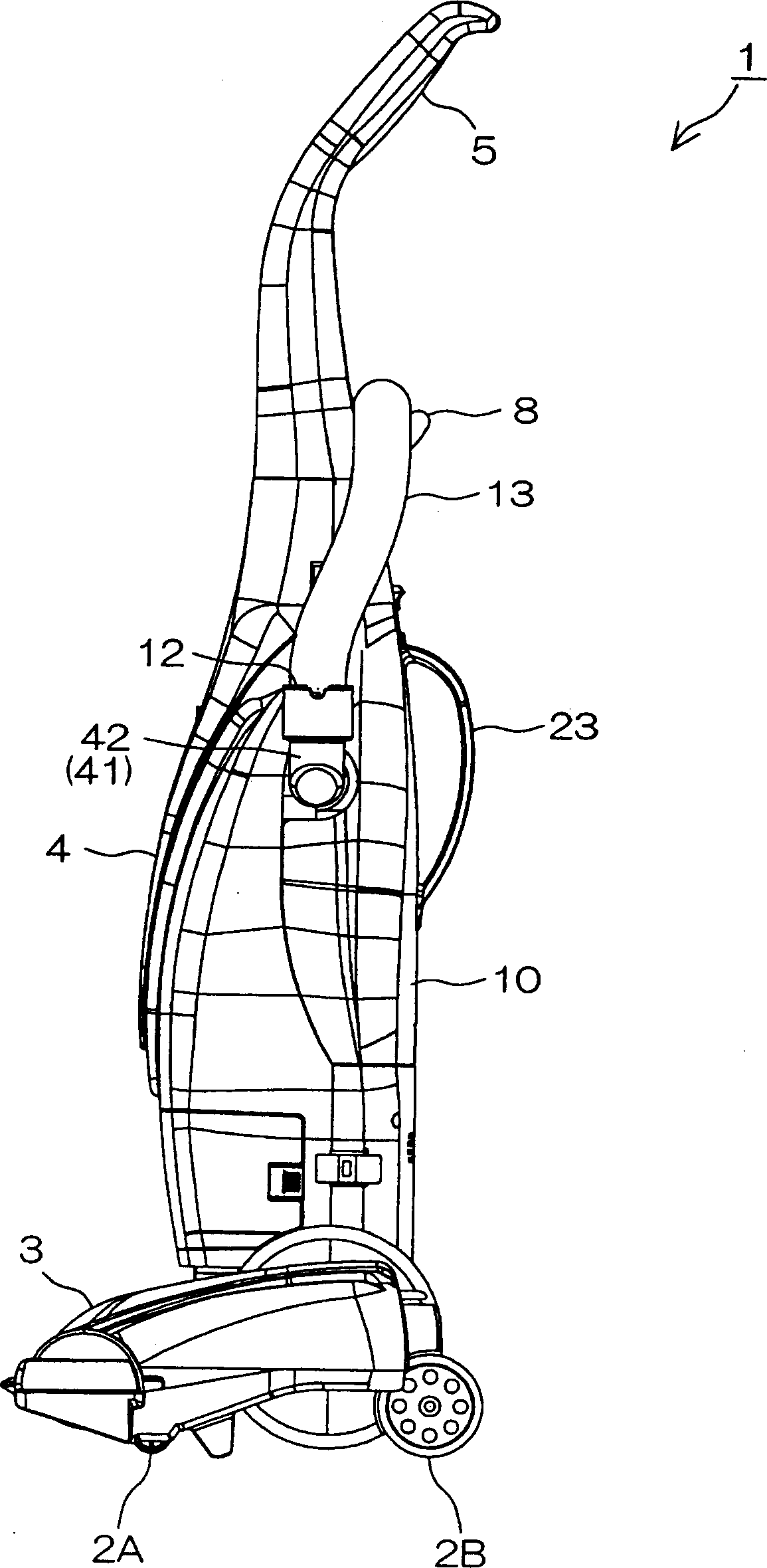

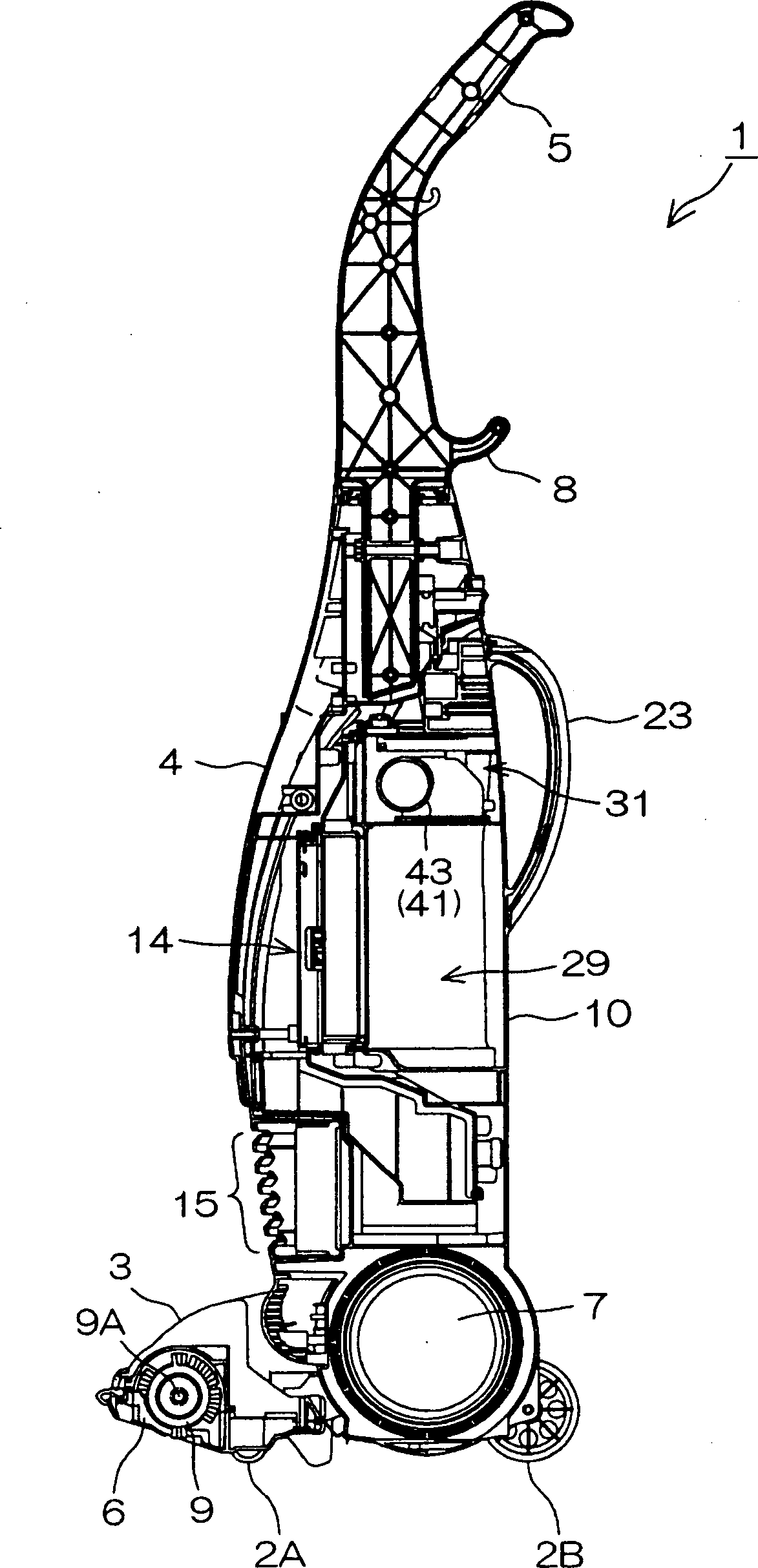

[0066] figure 1 It is a front view of the electric vacuum cleaner 1 which concerns on 1st Embodiment of this invention. figure 2 It is a left side view of this electric vacuum cleaner 1. image 3 It is a cross-sectional view of the electric vacuum cleaner 1 taken along a vertical plane in the front-rear direction as viewed from the left side.

[0067] refer to Figure 1 ~ Figure 3 The electric vacuum cleaner 1 is a so-called upright (vertical) vacuum cleaner, which is provided with a suction part 3 that moves along the ground, and a long strip-shaped main body 4 that is rotatably mounted on the suction part 3 at one end (lower end). It can be used in a posture of holding the handle 5 formed at the other end (upper end) of the main body 4 and tilting the main body 4 rearward at a predetermined angle (for example, 60° to 80°) with respect to the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com