Vibrating slab tamper

A plate compaction and vibrating shaft technology, which is applied in the field of machines, tools or auxiliary equipment, can solve the problems of fast compaction, injury, and low productivity, and achieve the effects of avoiding unsafe accidents, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

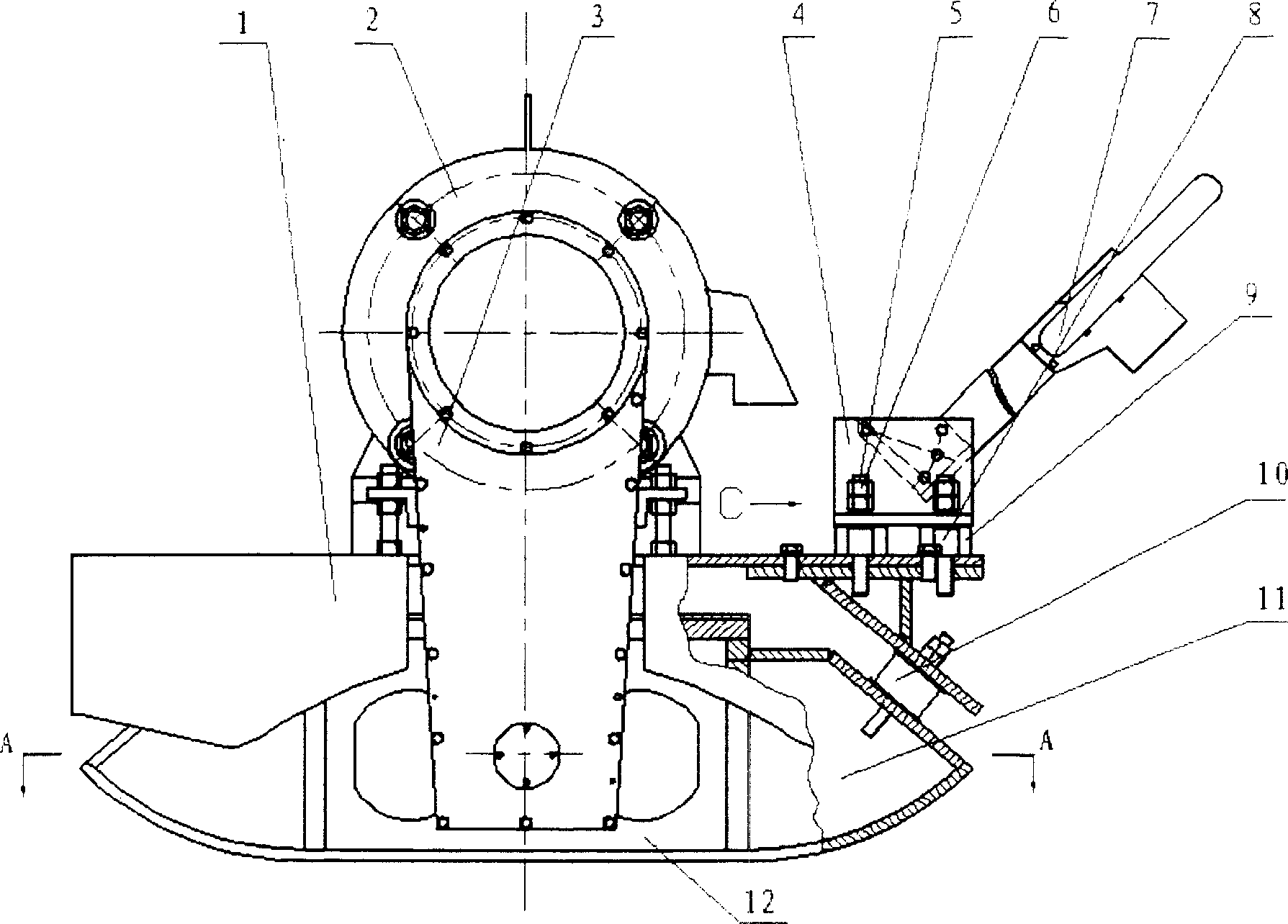

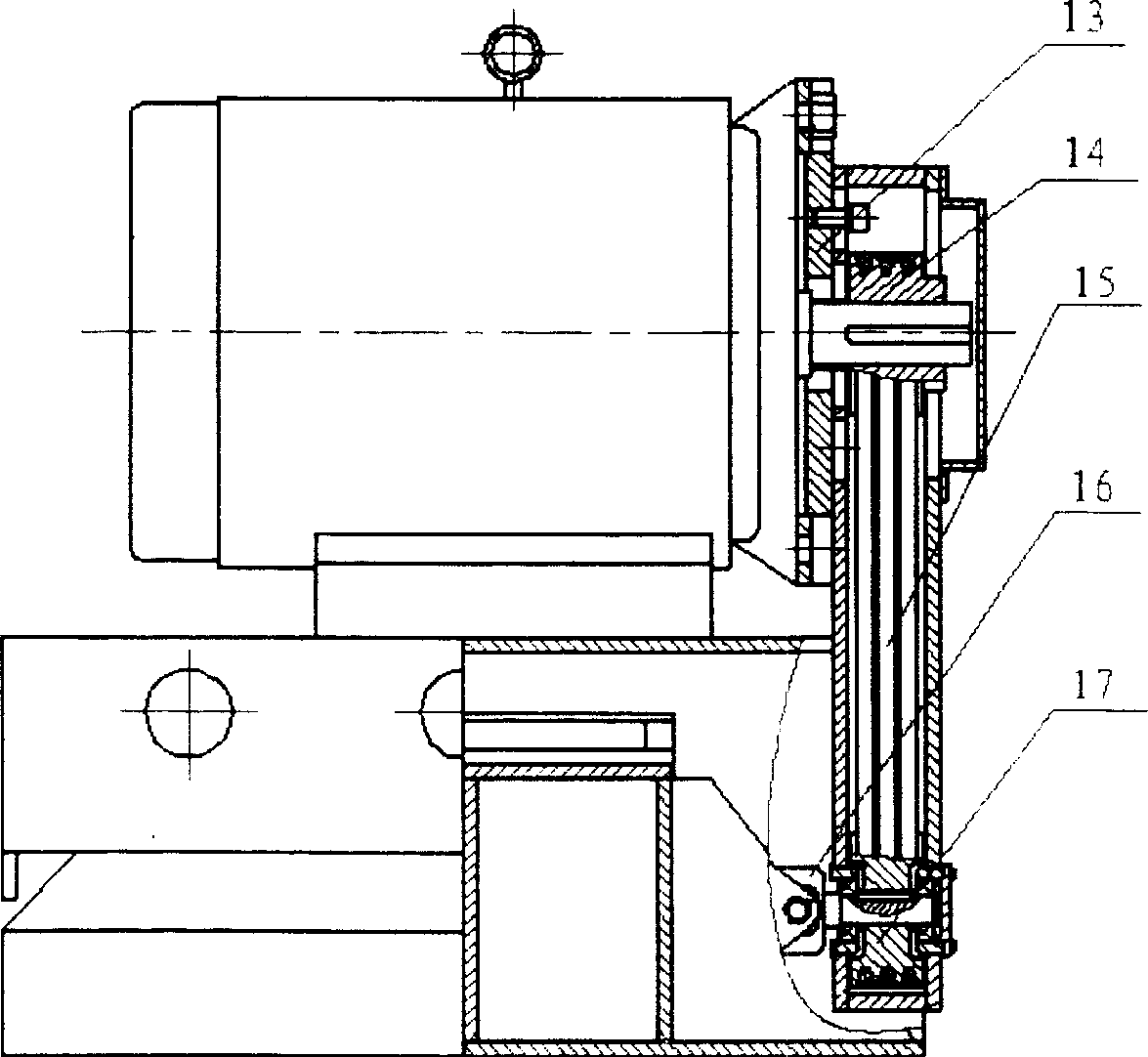

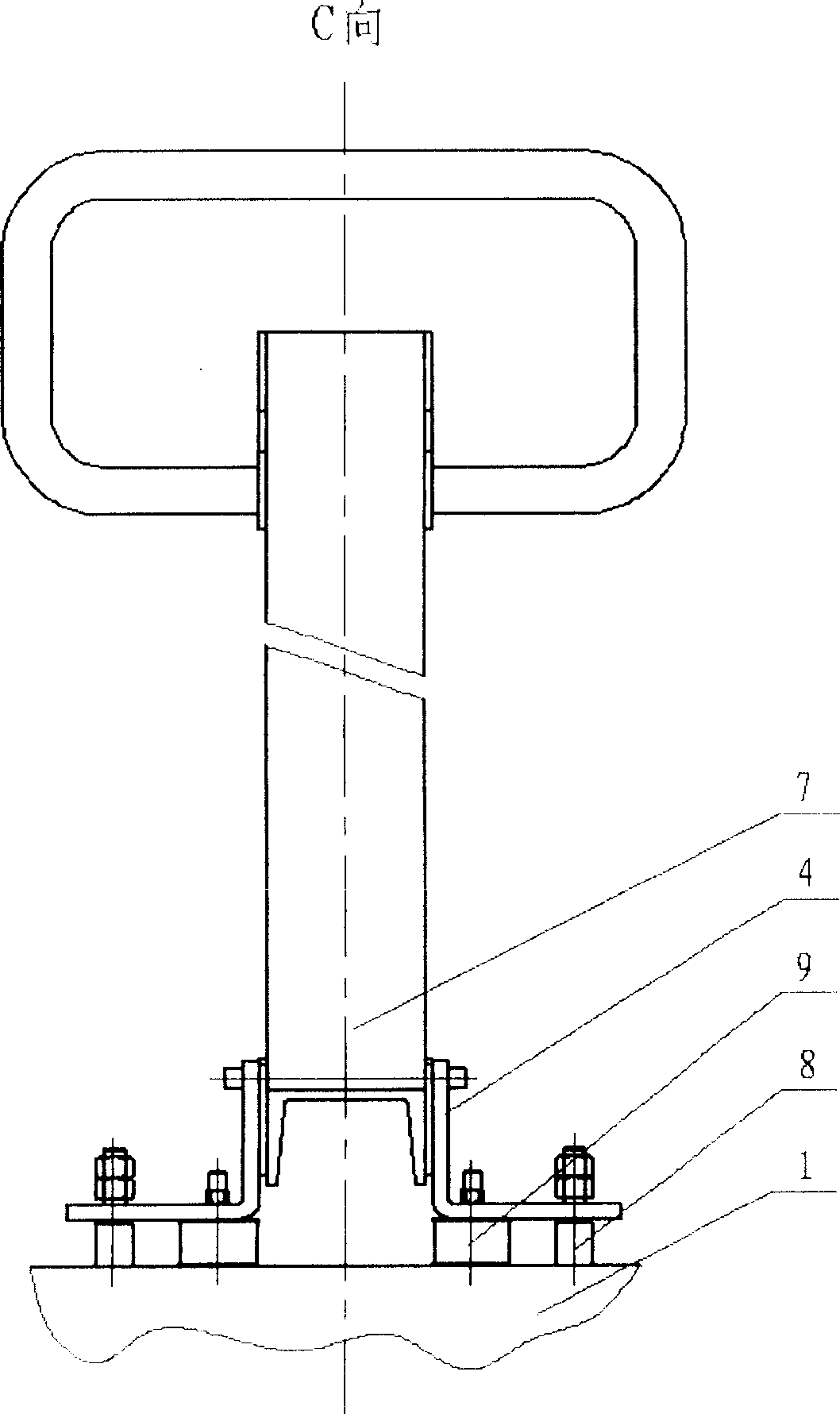

[0027] exist figure 1 , 2 , 3, 4, the vibrating plate compactor of the present embodiment is made of mounting plate 1, motor 2, pulley box 3, handrail seat 4, screw rod 5, nut 6, handrail 7, screw rod mounting seat 8, handrail rubber vibration damping on the frame Block 9, rubber damping block 10, frame lower mounting plate 11, loading mechanism 12, mounting flange 13, driving wheel 14, belt 15, universal joint 16, driven wheel 17 are connected and formed.

[0028] On the mounting plate 1 on the frame, a motor 2 is fixedly connected with a threaded fastening joint, and a mounting flange 13 is fixedly connected with a threaded fastening joint on the motor 2, and a threaded fastening joint is used on the lower mounting plate 11 of the frame. A loading mechanism 12 is fixedly connected, and an armrest seat 4 is fixedly connected to the mounting plate 1 on the frame with a threaded fastening joint, and an armrest is fixedly connected between the armrest seat 4 and the mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com