Colloid mill

A technology of colloid mill and static mill, applied in grain processing and other directions, can solve the problems of inflexible adjustment and easy damage of the adjustment ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

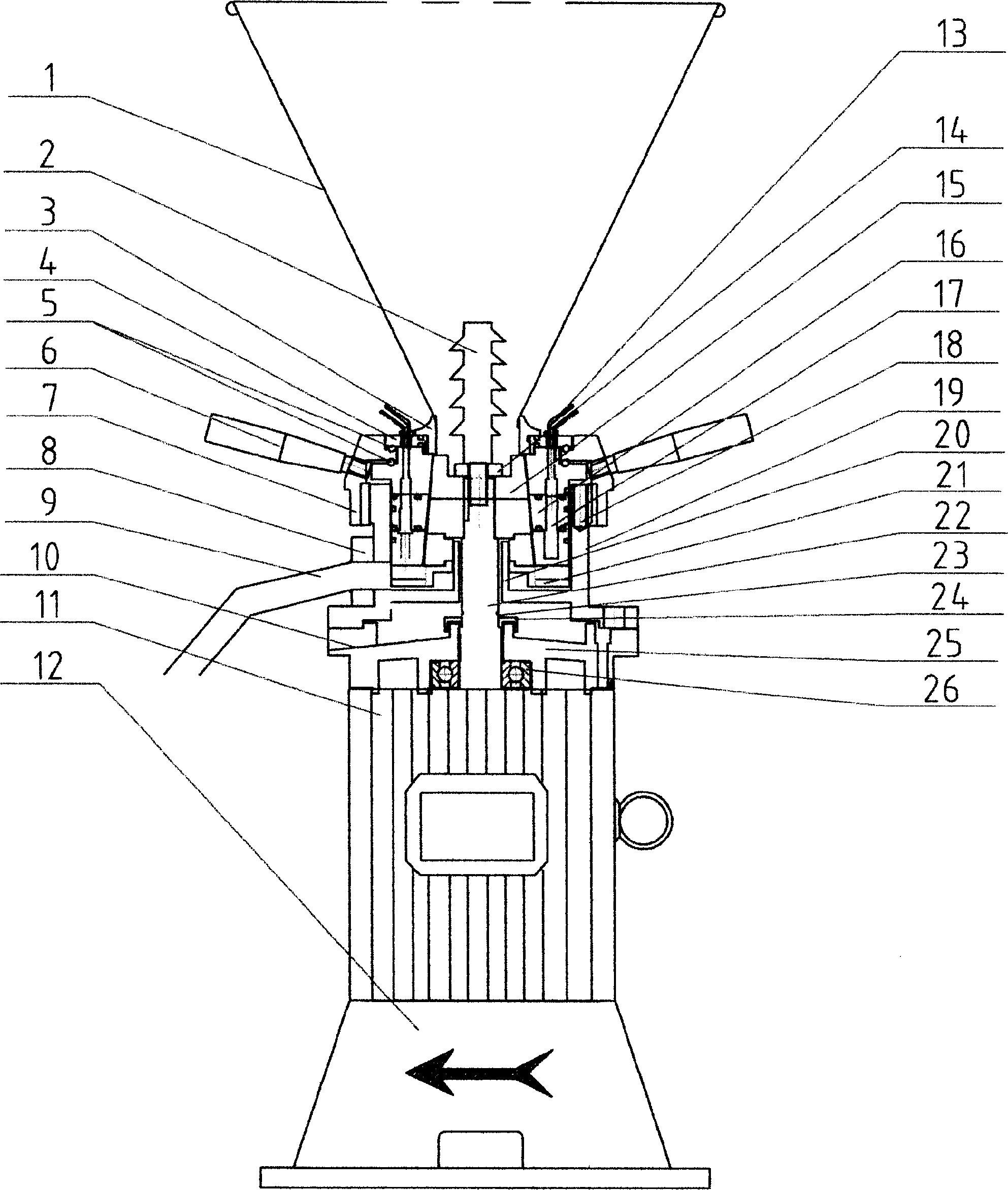

Image

Examples

Embodiment Construction

[0009] In the figure, a tripod (12) is arranged below the motor (11), and a bearing (26) is arranged at the upper main shaft (22) to cover it with an end cover (25), and the convex shape of the main shaft hole of the end cover (25) is arranged There is an oil seal (24) to prevent the leak-proof pipe (20) from seeping water, to ensure no leakage, an organism (19) is arranged on its end cover (25), and a leak-proof pipe and the body ( 19) into a whole, to replace the mechanical seal, the flat mouth of the leak-proof pipe is slightly higher than the discharge port (9), the main shaft (22) passes through the body (19), the leak-proof pipe (20) [shaft hole], the main shaft (22 ) is provided with a dynamic grinding body (15) on the shaft head, the dynamic grinding body (15) matches the static grinding body (16) arranged on the body, and the body (19) is provided with a static grinding body (16) The grinding body cooling channel (17) is connected and matched with the body (19), and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com