Electromagnetic interference eliminator for power system automation apparatus

A technology of automation equipment and electromagnetic interference, which is applied to electrical components, impedance networks, and AC networks to reduce harmonics/ripples, etc., to achieve good suppression effects, improve electromagnetic compatibility, and improve power quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1) Determination of capacitance parameters

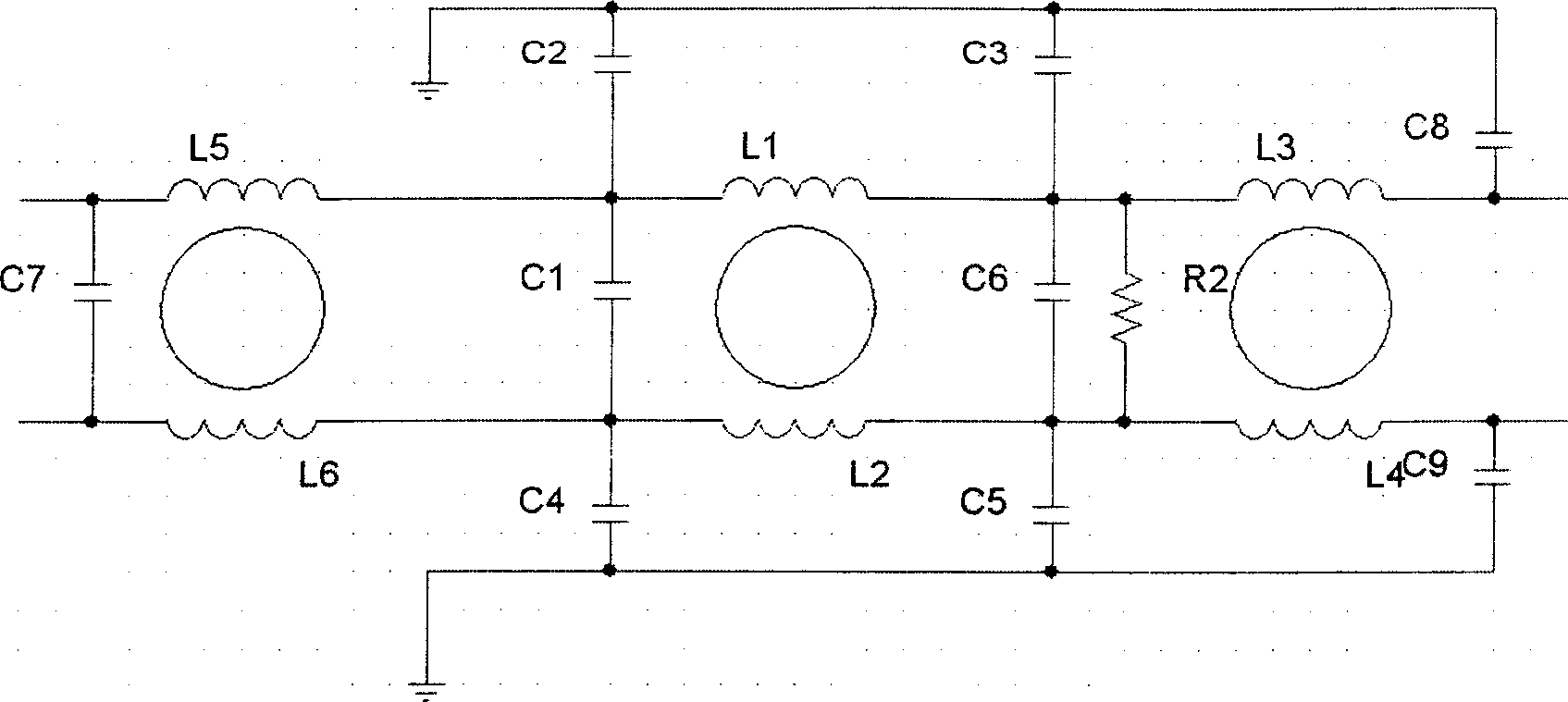

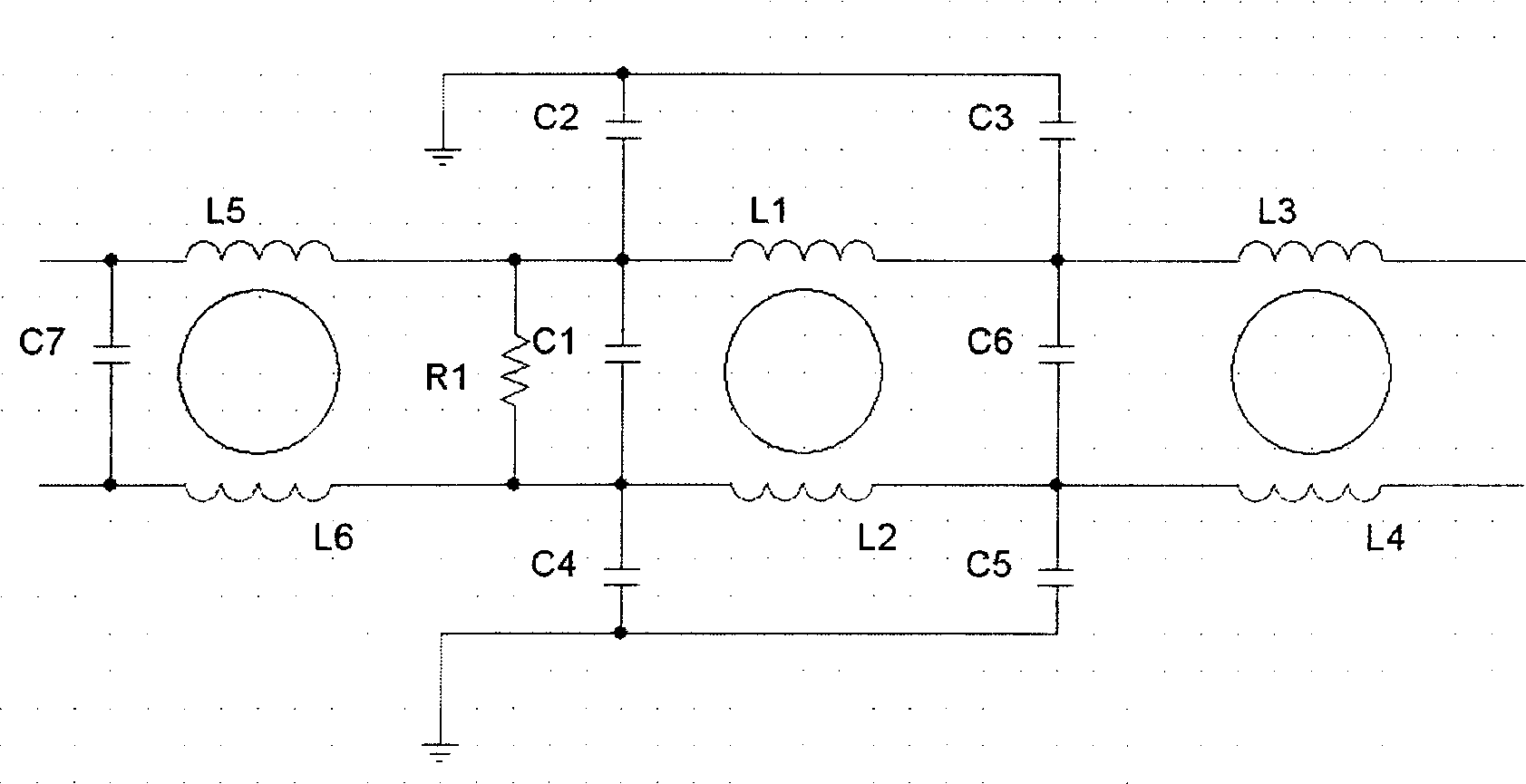

[0035] The various components in the electromagnetic interference filter such as figure 1 , figure 2 shown.

[0036] ① Determination of common mode capacitor parameters:

[0037] Select monolithic ceramic capacitors and feedthrough capacitors with good high-frequency performance as common-mode capacitors. If allowed, the larger the capacity requirement, the better, but if it is too large, the leakage current will be large. Considering the limitation of the leakage current in the design, the capacitance values of capacitors C2, C3, C4, and C5 are all 2200pF, and the withstand voltage is AC 2000V; The value is 1000pF, and the withstand voltage is DC 2000V, which is suitable for high frequency.

[0038] ② Determination of differential mode capacitance parameters:

[0039] Where possible, the larger the capacity requirement, the better. In general, the required value is between 1-5uf (for each capacitor). Since the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com