Optical member,optical connector and electronic parts and instrument

A technology for optical devices and electronic devices, which is applied in the direction of printed circuits, electrical solid devices, and semiconductor devices connected with non-printed electrical components. It can solve problems such as non-transfer molding technology and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

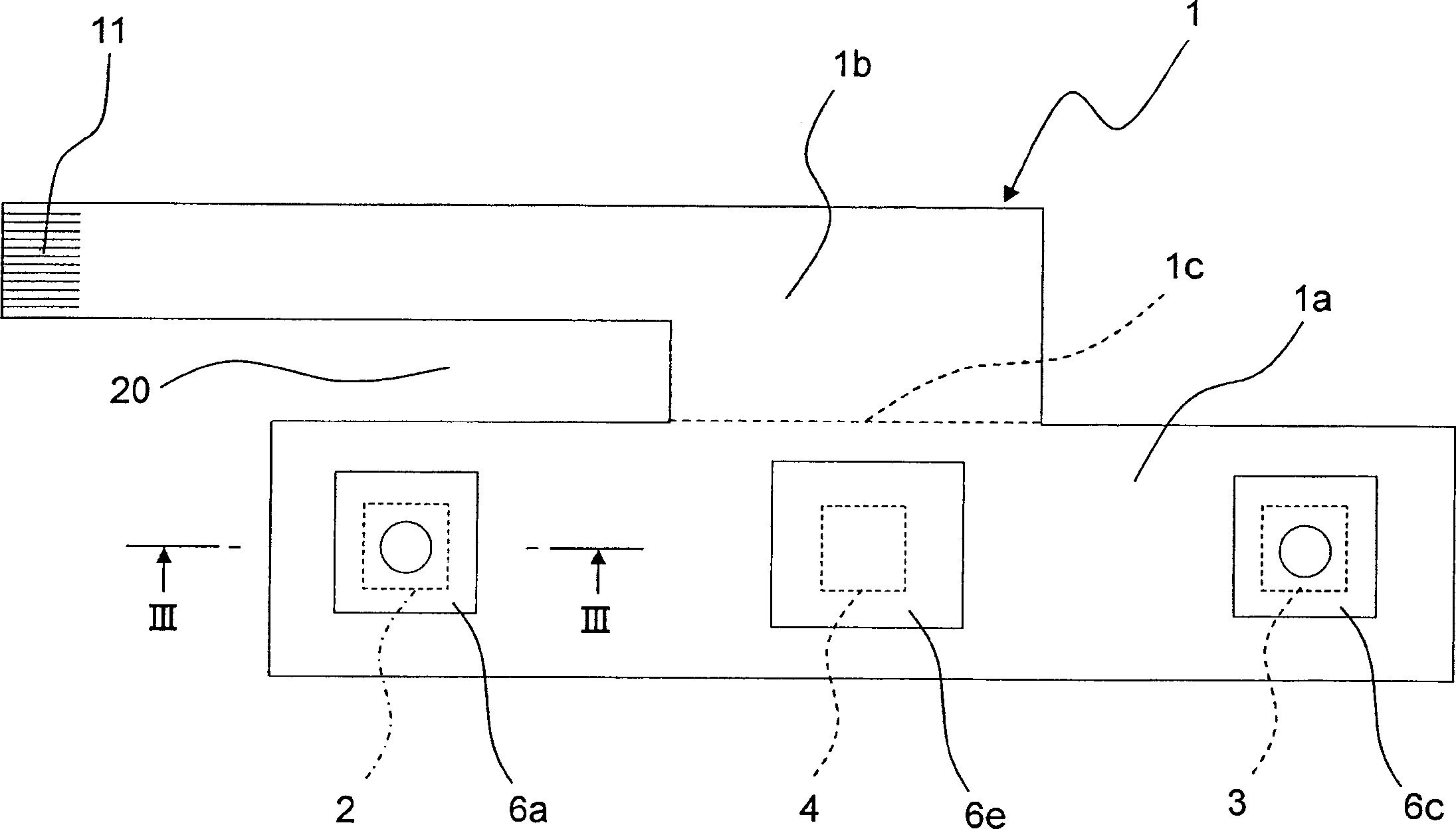

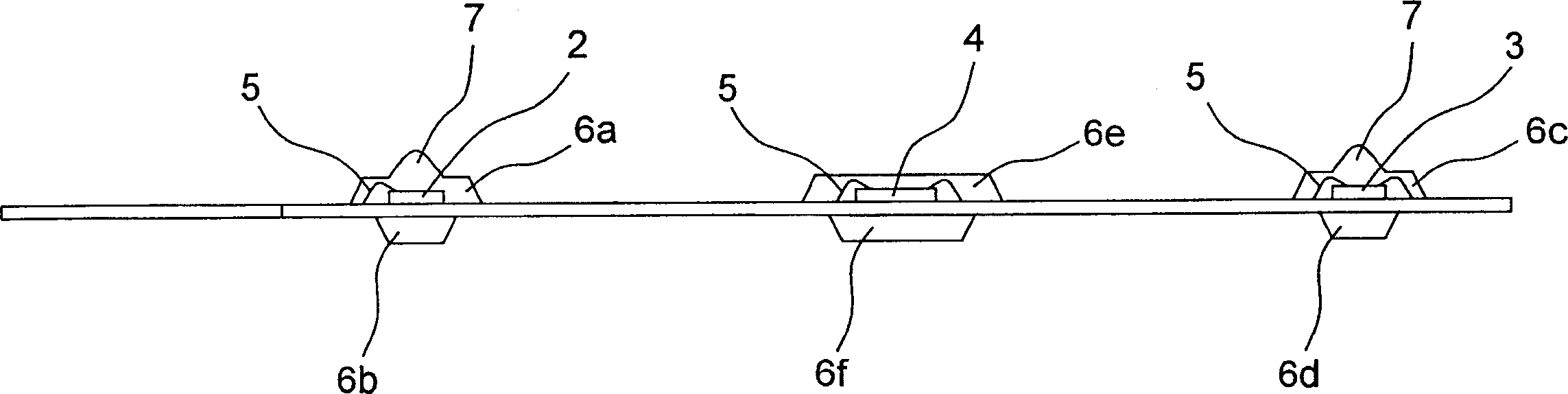

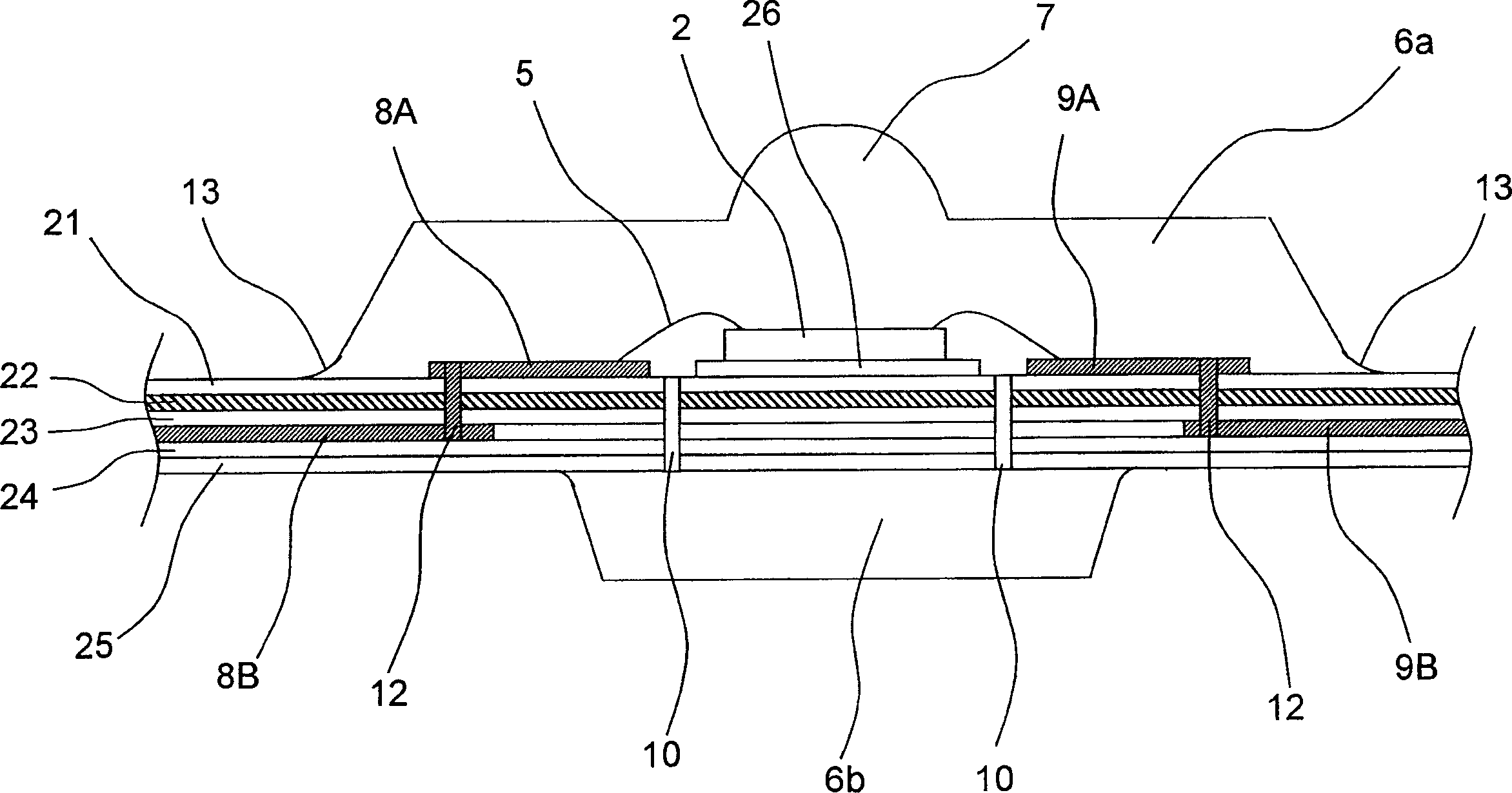

[0070] figure 1 It is a plan view of an optical device which is an example of the electronic device according to the first embodiment of the present invention, figure 2 From figure 1 Side view of the aforementioned optics seen below. Such as figure 1 As shown, the flexible substrate 1 has: a rectangular body portion 1a; an extension portion 1b extending from the center of the body portion 1a to the side and bent in the longitudinal direction of the body portion 1a. An external connection terminal 11 is provided at the front end of the extension portion 1b of the above-mentioned flexible substrate 1 . In addition, the above-mentioned flexible substrate 1 includes a flexible base substrate 22 (shown in image 3 ), a first wiring pattern (including image 3 electrode parts 8A, 9A), and on the other side of the base substrate 22, a second wiring pattern (including image 3The electrode part 8B, 9B). A part of at least one of the first and second wiring patterns of the flex...

no. 2 Embodiment approach

[0100] Figure 4 It is a cross-sectional view of an optical device which is an example of an electronic component according to a second embodiment of the present invention. The optical device according to the second embodiment has the same configuration as the optical device according to the first embodiment except for a reinforcing material, and the same components use The same symbol, the description is omitted, and the figure 1 , figure 2 .

[0101] Such as Figure 4 As shown, on the outer peripheral parts connected to the flexible substrate 1 of the first and second sealing bodies 6a and 6b of the first and second molded resin parts, a hard resin (for example, polyimide film) is provided. Reinforcement material 14A, 14B. Also, other hard materials such as Dami-like metals can also be used as the reinforcing materials 14A and 14B.

[0102] In the optical device of the above-mentioned second embodiment, the mold clamping pressure applied to the flexible substrate 1 dur...

no. 3 Embodiment approach

[0105] Figure 5 It is a schematic top view of an optical connector using an optical device as an example of an electronic component according to the third embodiment of the present invention. The optical connector of the third embodiment adopts the optical device of the first embodiment, citing figure 1 , figure 2 .

[0106] The optical device of the above-mentioned first embodiment, such as figure 2 As shown, the light-emitting element 2, light-receiving element 3, and communication IC 4 are sealed with independent first sealing bodies 6a, 6c, and 6e by transfer molding, so that leakage of resin to unintended areas can be suppressed. Thus, on the exposed area of the flexible substrate 1, the bypass capacitor 15, the resistive element 16, the crystal oscillator 17, etc., which are examples of the capacitive elements necessary for the light-emitting element 2, the light-receiving element 3, and the communication IC 4, are provided by soldering.

[0107] The optical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com