Facing tile and its preparation method

A production method and technology for facing bricks, which are applied in special decorative structures, techniques for producing decorative surface effects, decorative arts, etc. Vivid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

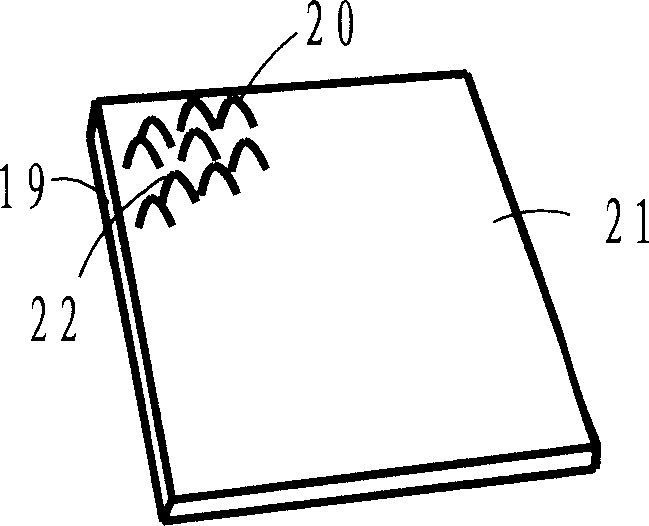

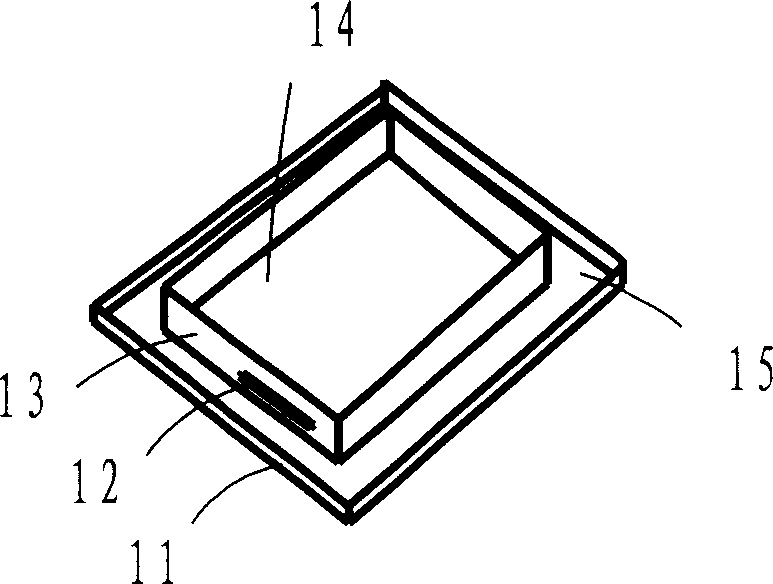

[0041] see Figure 1 to Figure 4 . The serial numbers in the attached drawings represent: discharge port 1, drum 2, spiral blade 3, water delivery pipe 4, feed hopper 5, gear 6, gearbox 7, motor 8, machine foot 9, frame 10, outer frame 11. Overflow tank 12, inner frame edge 13, inner template 14, template 15, bracket 16, vibration motor 17, vibration platform 18, base layer 19, cobblestone 20, finish layer 21, gap 22.

[0042] In this embodiment, pebbles 20 are used as the raw material exposed outside, a part of which is exposed on the finish layer 21 , and the height can be set as required, and the other part is inserted into the finish layer 21 and the base layer 19 . The base layer 19 is formed by mixing and solidifying cement and sand. There are gaps 22 between the adjacent exposed pebbles 20 , and the distance from the top of each exposed pebble 20 to the finish layer 21 is equal, that is, the tops of each pebble 20 are on the same plane.

[0043] The production method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com