Process method of small eccentricity multi-eccentric and bidirectionally eccentric axle

A processing method and technology of eccentricity, applied in the direction of metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low machining accuracy, high cost, and demand for eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

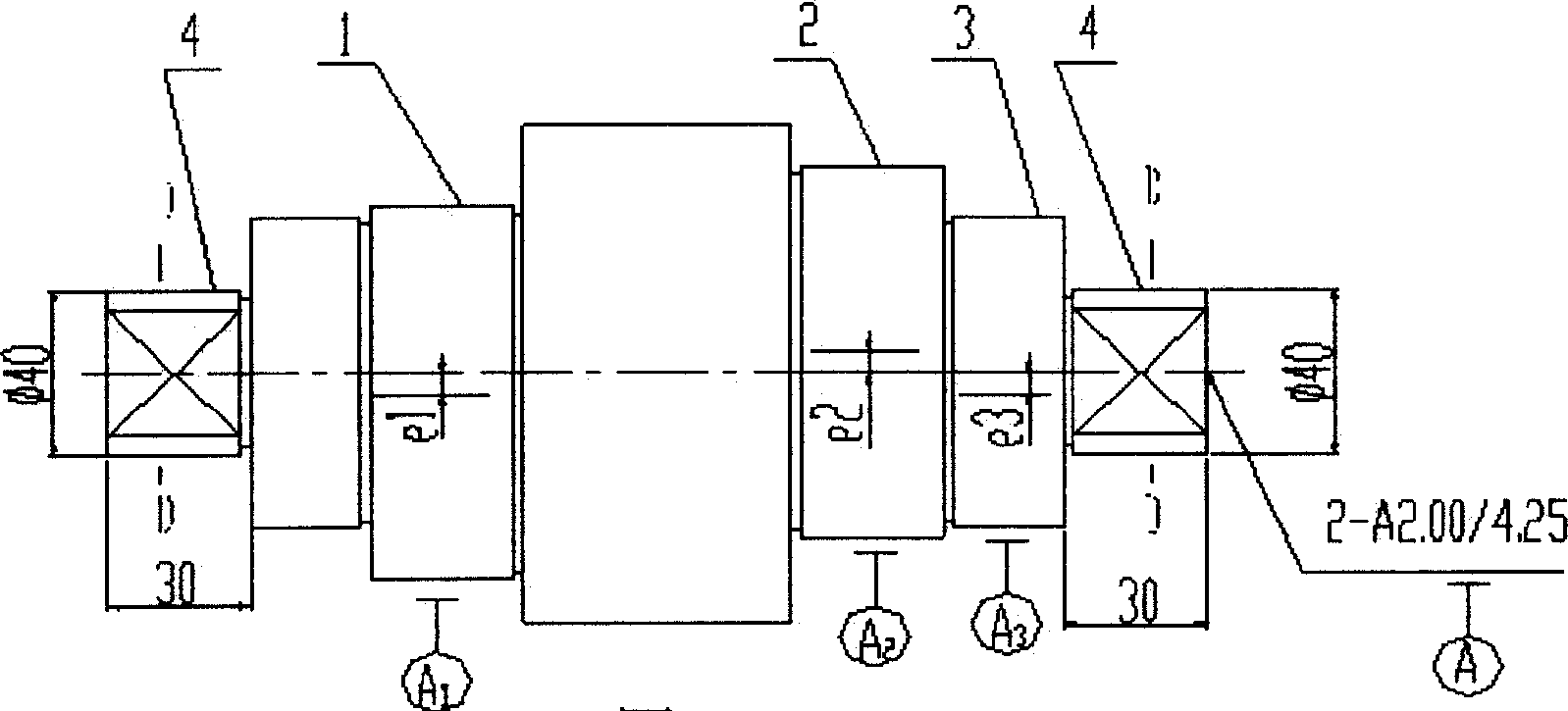

[0019] Process a batch of eccentric shafts, the eccentric shaft has two eccentric outer circles, namely A 1 Reference outer circle 1 and A 2 Reference outer circle 2, and the eccentric directions of the two eccentric outer circles are opposite, forming an angle of 180°; A 1 The eccentricity of reference outer circle 1 is e 1 =3mm, A 2 The eccentricity of the reference outer circle 2 is e 2 =3mm;

[0020] In order to meet the requirements, the following processes and methods are adopted:

[0021] First, the processing of shaft blanks.

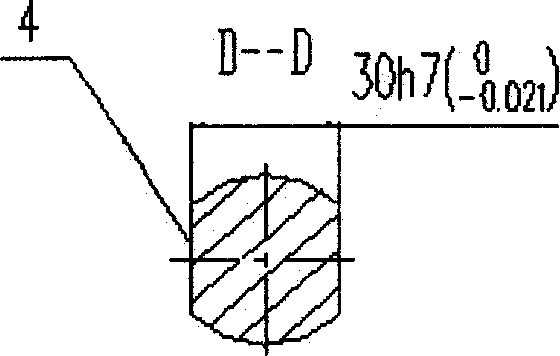

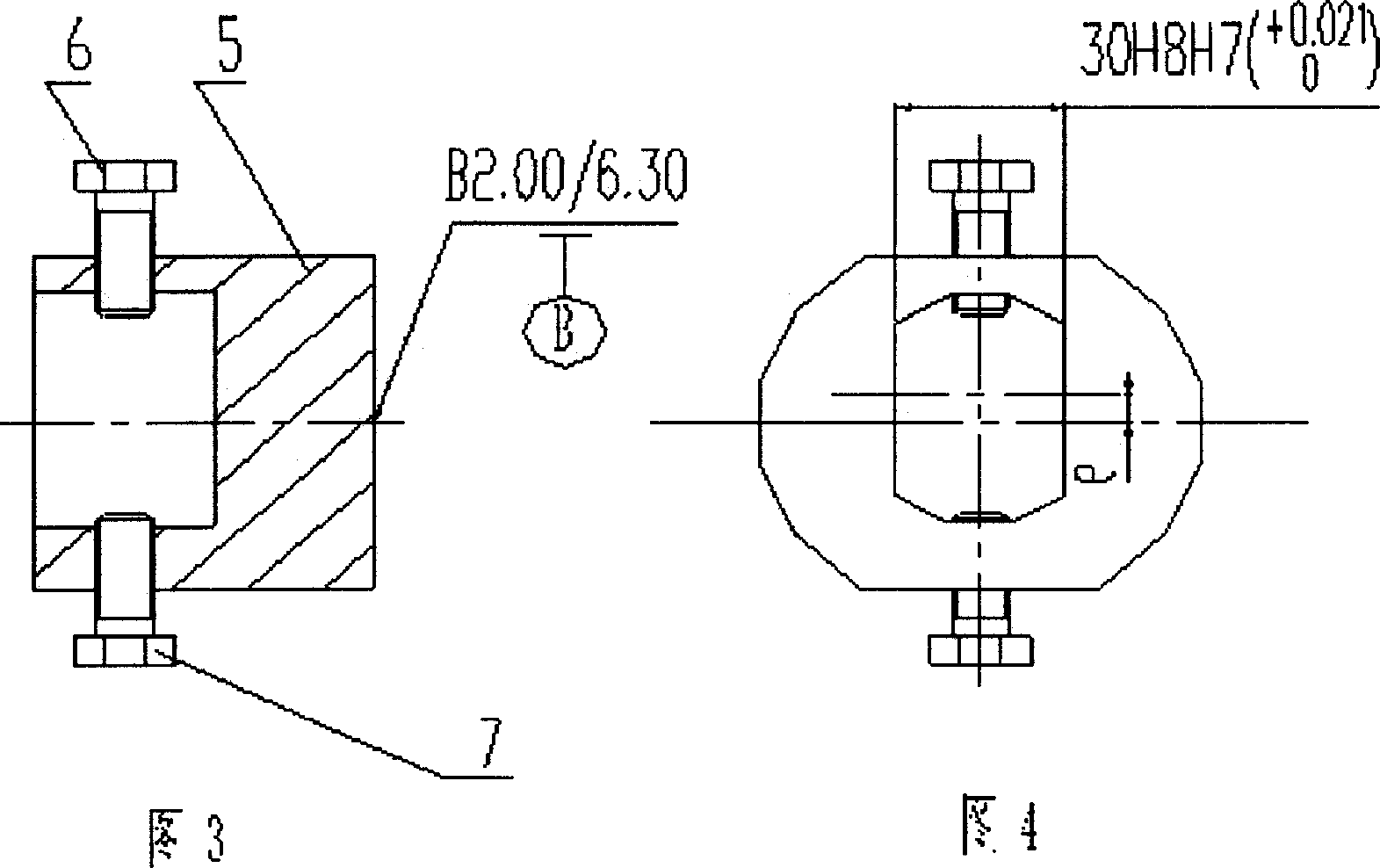

[0022] ①According to the dimensional accuracy requirements of the outer circle of the A datum, the machining method of fine turning or grinding is adopted, and all the outer circles of the A datum are processed to the drawing requirements. A 1 Reference outer circle 1 and A 2 The reference outer circle 2 is left with a machining allowance of 2-3mm, and at the same time, a 30mm long craftsman 4 is left at each end of the shaft.

[0023] ②Press figure...

Embodiment 2

[0033] Example 2: Processing a batch of eccentric shafts, the eccentric shaft has three eccentric outer circles, namely A 1 Reference outer circle 1, A 2 Reference outer circle 2 and A 3 Reference outer circle 3, A 1 Reference outer circle 1, A 2 The reference outer circle 2 is eccentric in the same direction, A 3 The reference outer circle 3 is eccentric in the opposite direction, that is, an included angle of 180° is formed; A 1 The eccentricity of reference outer circle 1 is e 1 =2.5mm, A 2 The eccentricity of the reference outer circle 2 is e 2 =3.5mm, A 3 The eccentricity of the reference outer circle 3 is e 3 =3mm;

[0034] In order to meet the requirements, the following processes and methods are adopted:

[0035] First, the processing of shaft blanks.

[0036] ①According to the dimensional accuracy requirements of the outer circle of the A datum, the machining method of fine turning or grinding is adopted, and all the outer circles of the A datum are processed to the drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com