Method for adjusting center of gravity of cooler trough, and reduction of wandering and gnawing track of cartwheel

A ring cooler and center of gravity technology, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve problems such as thrust not exceeding the center of gravity, high failure rate of ring coolers, and non-overlapping centers of gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

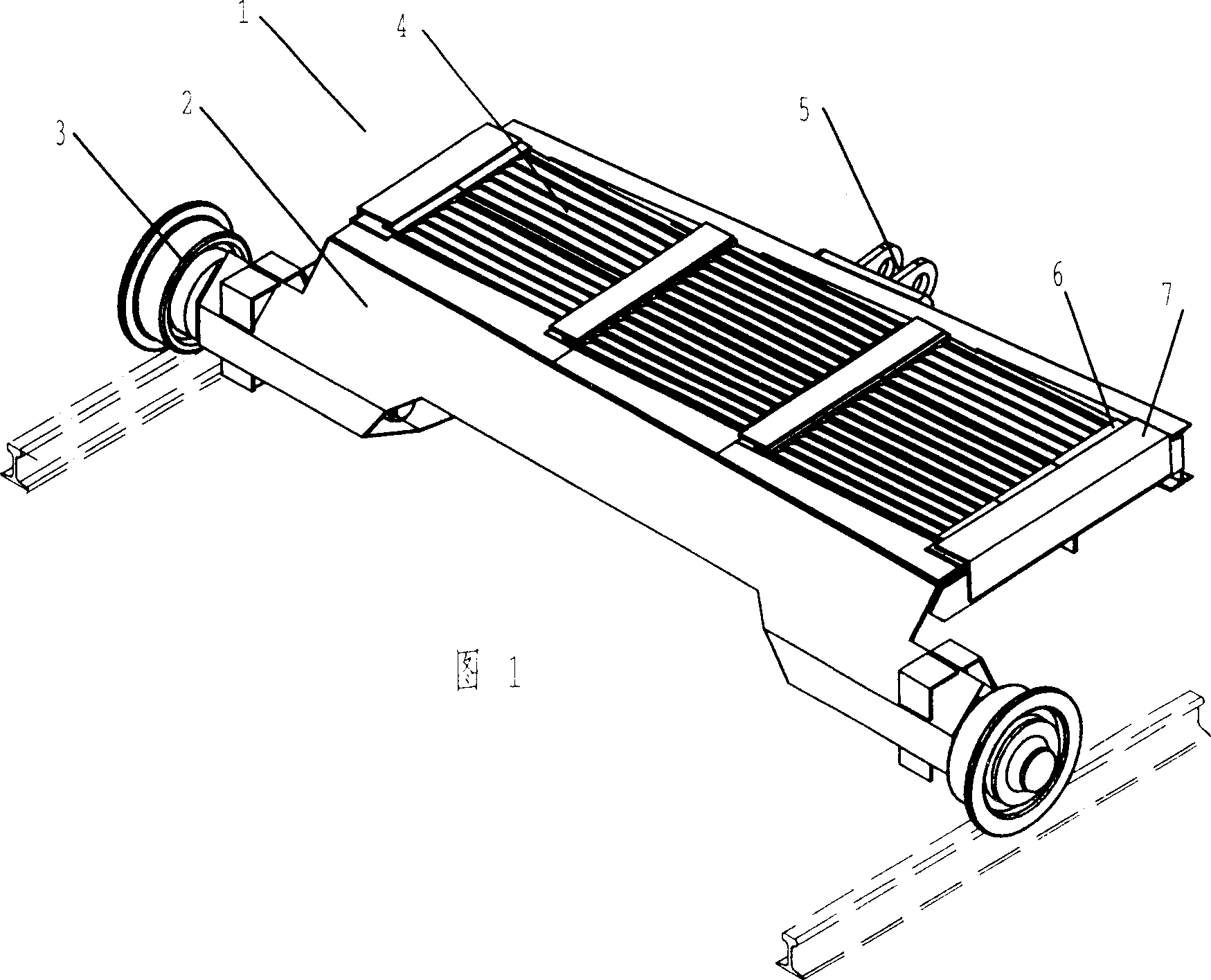

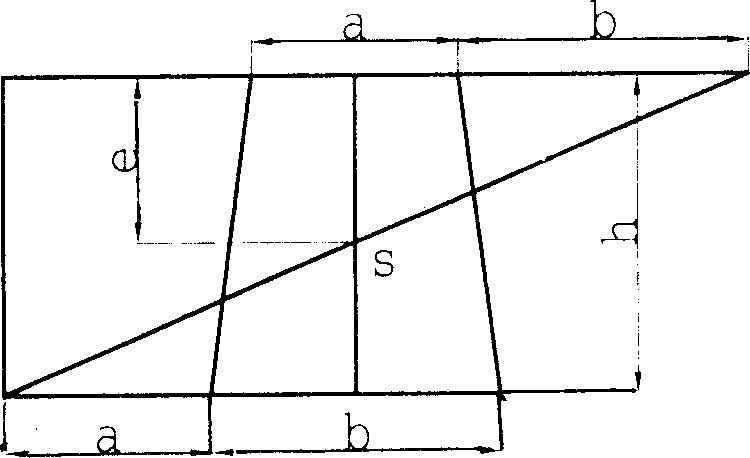

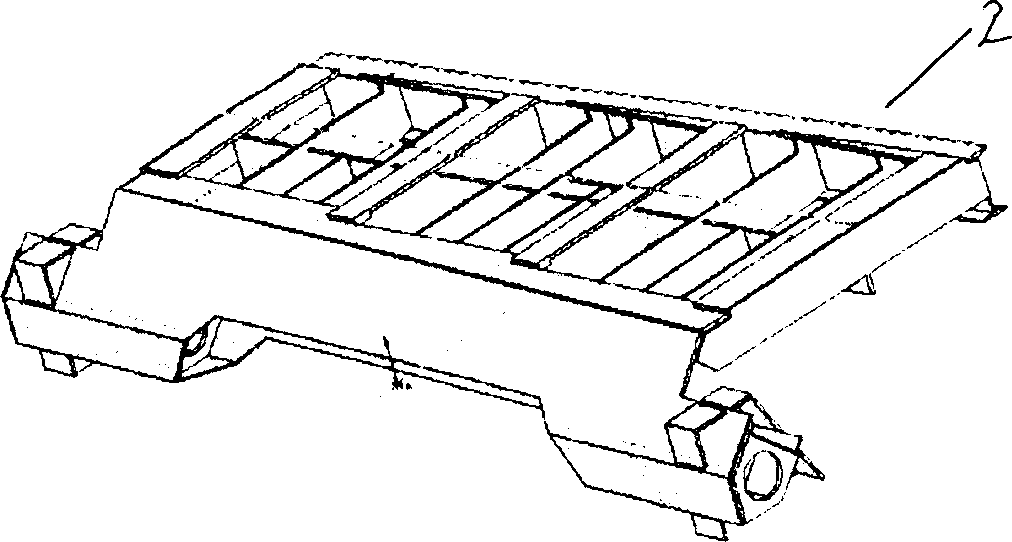

[0023] The body of the ring cooler machine is shown in Figure 1. Because the track of the trolley is a circle, the material-bearing surface of the trolley body 1 is trapezoidal, and the upper part of the trolley body is provided with a grate plate 4 to form a trapezoidal material-bearing surface, and a lug 5 is installed on one waist of the trapezoid. Wheel 3 is installed on a waist. The inner and outer slewing frame beams on both sides of the trolley are equipped with guard plates (the weight of the guard plate is not borne by the trolley, so it is not shown in Figure 1). When the trolley distributes materials evenly, it can be considered that the pile of sintered materials has a cross-section of Trapezoidal cylinder, the center of gravity of the material pile passes the geometric center of gravity of the trapezoidal material receiving surface of the trolley. The design of the lug position of the trolley body is based on the heavy vehicle. The eccentric weight of the trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com