Process and plant for producing metal oxide from metal compounds

A technology of metal compounds and oxides, applied in the direction of aluminum compounds, chemical instruments and methods, oxygen/ozone/oxides/hydroxides, etc., can solve problems such as difficulties in calcination devices, and achieve the effect of prolonging process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

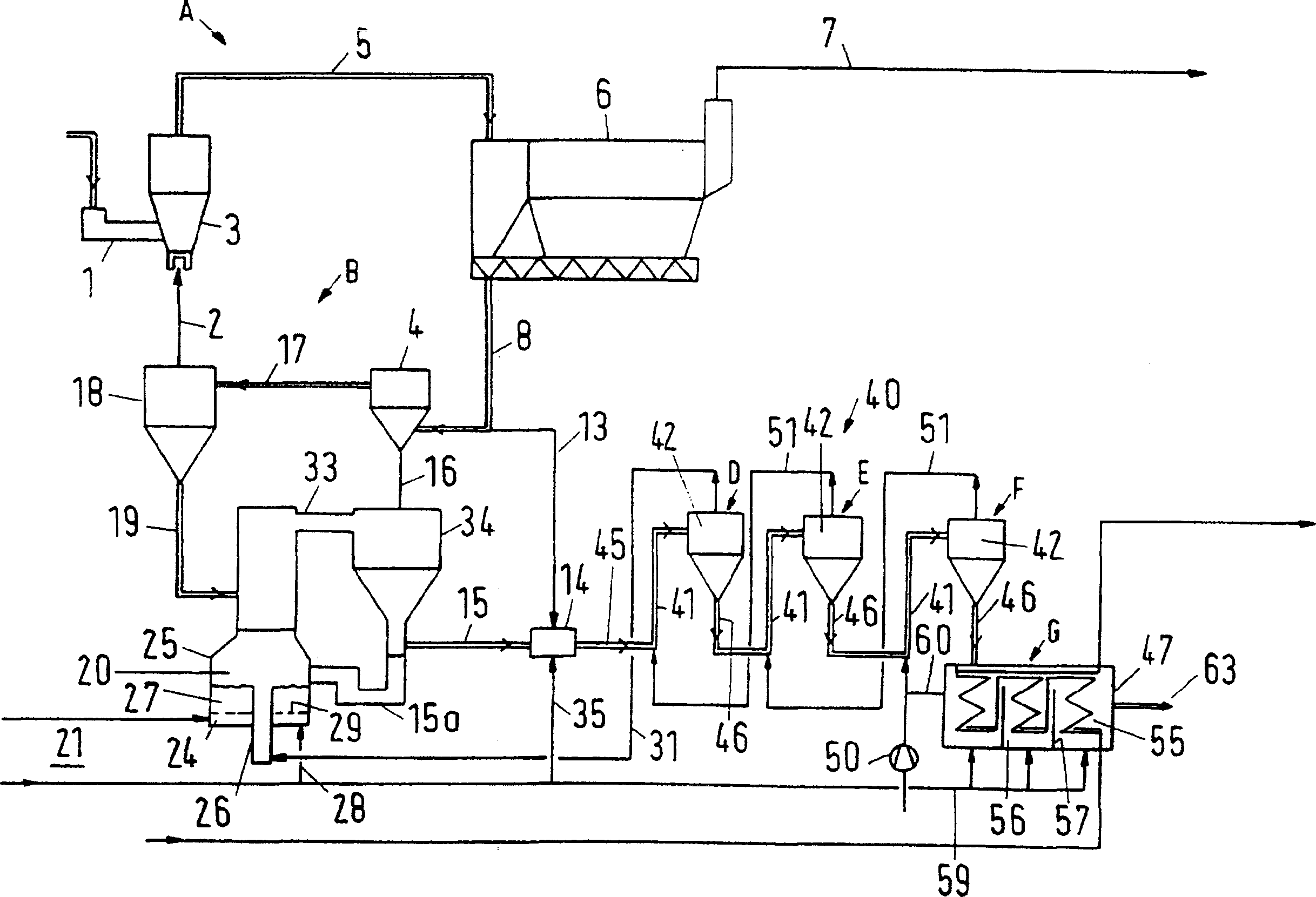

[0064] Embodiment 1 (production alumina)

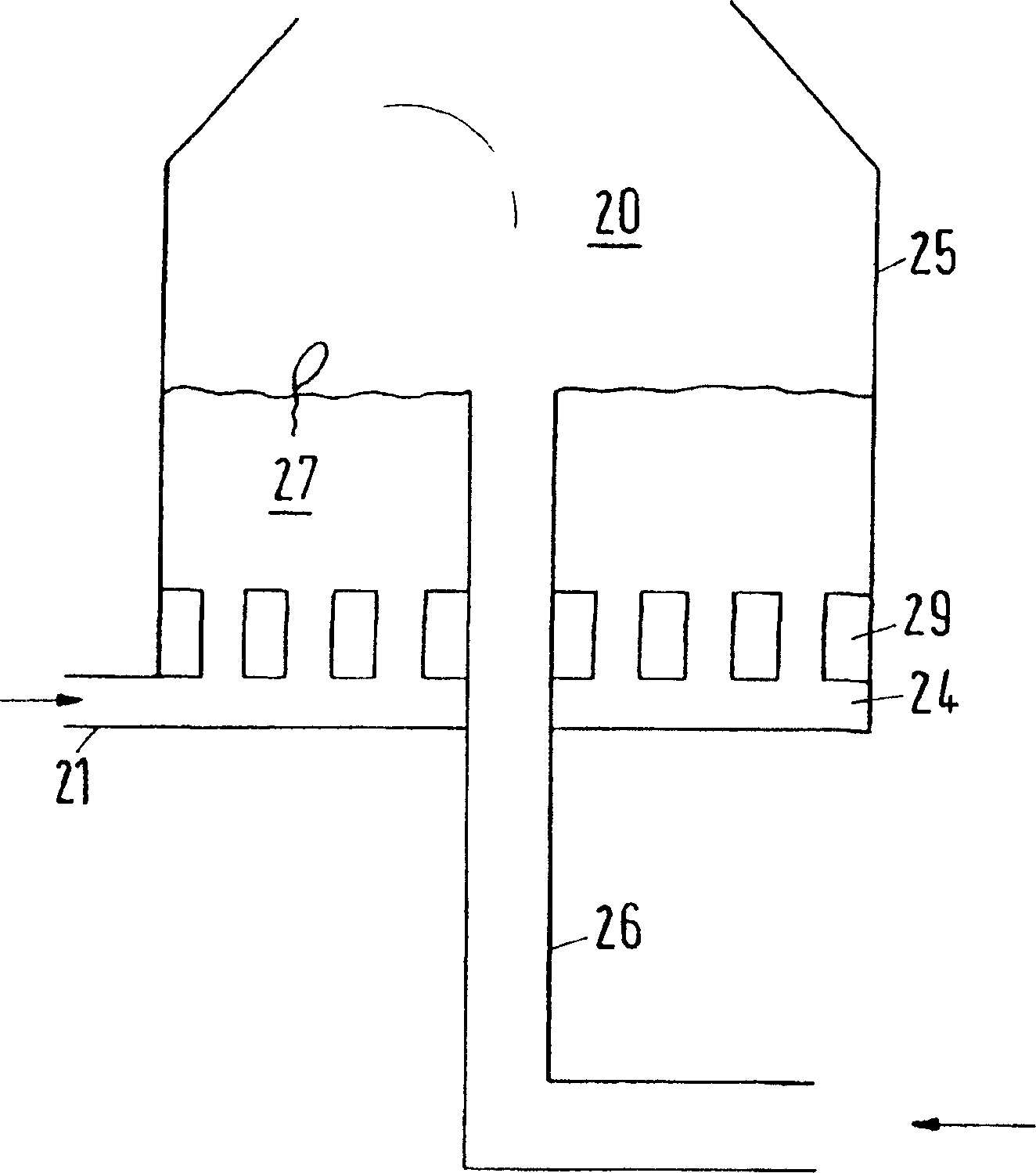

[0065] exist figure 1 In the device, about 213000 kg / h of alumina with a temperature of 65° C. and a surface moisture of 8.0 wt % is supplied through a screw conveyor 1 . One part of the alumina preheated in the first preheating zone A is introduced into the mixing chamber 14 and seven parts are introduced into the second preheating zone B. After passing through the second preheating section B, the temperature of the solid in the solid pipeline 19 is 341° C., and it is preheated to the extent that about 70% of bound water is removed. 9750Nm 3 The cold natural gas per h is introduced into the annular fluidized bed 27 of the fluidized bed reactor 25 through the fuel pipeline 21 as fuel.

[0066] In such an application, the Froude number Fr of the particles in the fixed annular fluidized bed p About 0.17, the particle Froude number Fr in the mixing chamber p About 2.96, the particle Froude number Fr in the central tube p About 9.9....

Embodiment 2

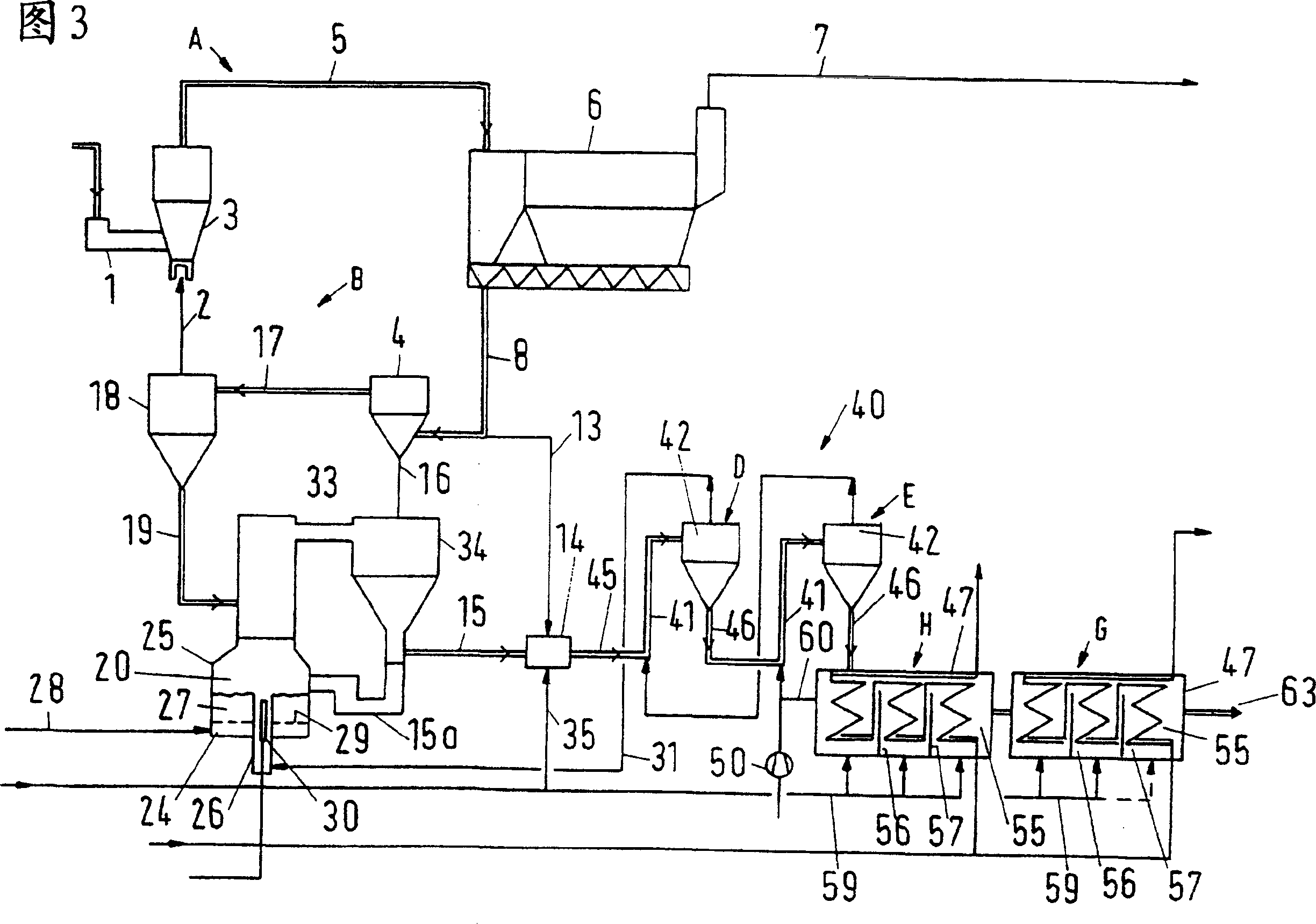

[0070] Embodiment 2 (production alumina)

[0071] In the plant of FIG. 3 , approximately 102,000 kg / h of aluminum hydroxide at a temperature of 65° C. and a surface moisture of 7.0 wt % is supplied via a screw conveyor 1 . One part of the aluminum hydroxide preheated in the first preheating section A is introduced into the mixing chamber 14, and eight parts are introduced into the second preheating section B. After passing through the second preheating section B, the temperature of the solid in the solid pipeline 19 is 343° C., and it is preheated to the extent that about 72% of bound water is removed. Will 5027Nm 3 Cold natural gas per hour is supplied as fuel to the fluidized bed reactor 25 through the lances 30 extending into the center pipe 26 and the mixing chamber 20 .

[0072] In such an application, the Froude number Fr of the particles in the fixed annular fluidized bed p About 0.34, the particle Froude number Fr in the mixing chamber p About 1.54, the particle Fr...

Embodiment 3

[0076] Embodiment 3 (preheating with annular fluidized bed heating section)

[0077] according to Figure 5 , for particularly efficient and gentle preheating, two of the first and second preheating sections A, B are replaced by annular fluidized bed heating sections 70, 71 with a chamber for a fixed annular fluidized bed 72 and a mixing chamber 73 Venturi preheater 3,4. In the first preheating step, the wet solids are surface dried and heated to a temperature of about 150°C. In the second preheating section B, the solid is then precalcined, in which about 70% of the bound water is removed, while further heating to about 350°C. In the first step, for example, 196t / h of wet hydrated alumina at a temperature of 65°C can be loaded into the annular fluidized bed 72 of the annular fluidized bed heating section 70 of the first preheating section A, and heated by 5000Nm 3 / h of air fluidization. Fluidizing air is introduced into the annular fluidized bed 72 through a feed line 74...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com