Suspension magnet of high speed magnetic suspension train and manufacturing method thereof

A suspended magnet and maglev technology, applied in the field of electromagnets, can solve the problems of large magnetic loss, complex thermal insulation layer and manufacturing process, eliminate the phenomenon of magnetic flux density saturation, ensure the insulation and heat dissipation effect, and increase the excitation current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

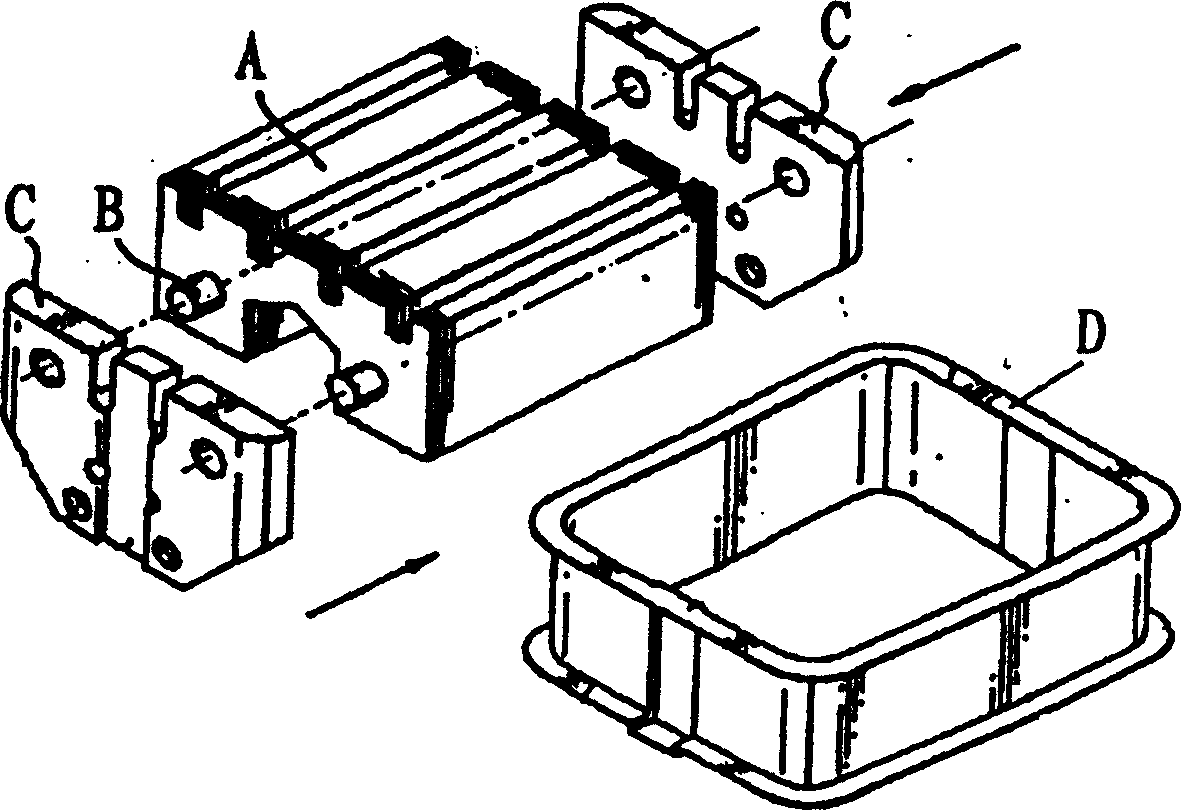

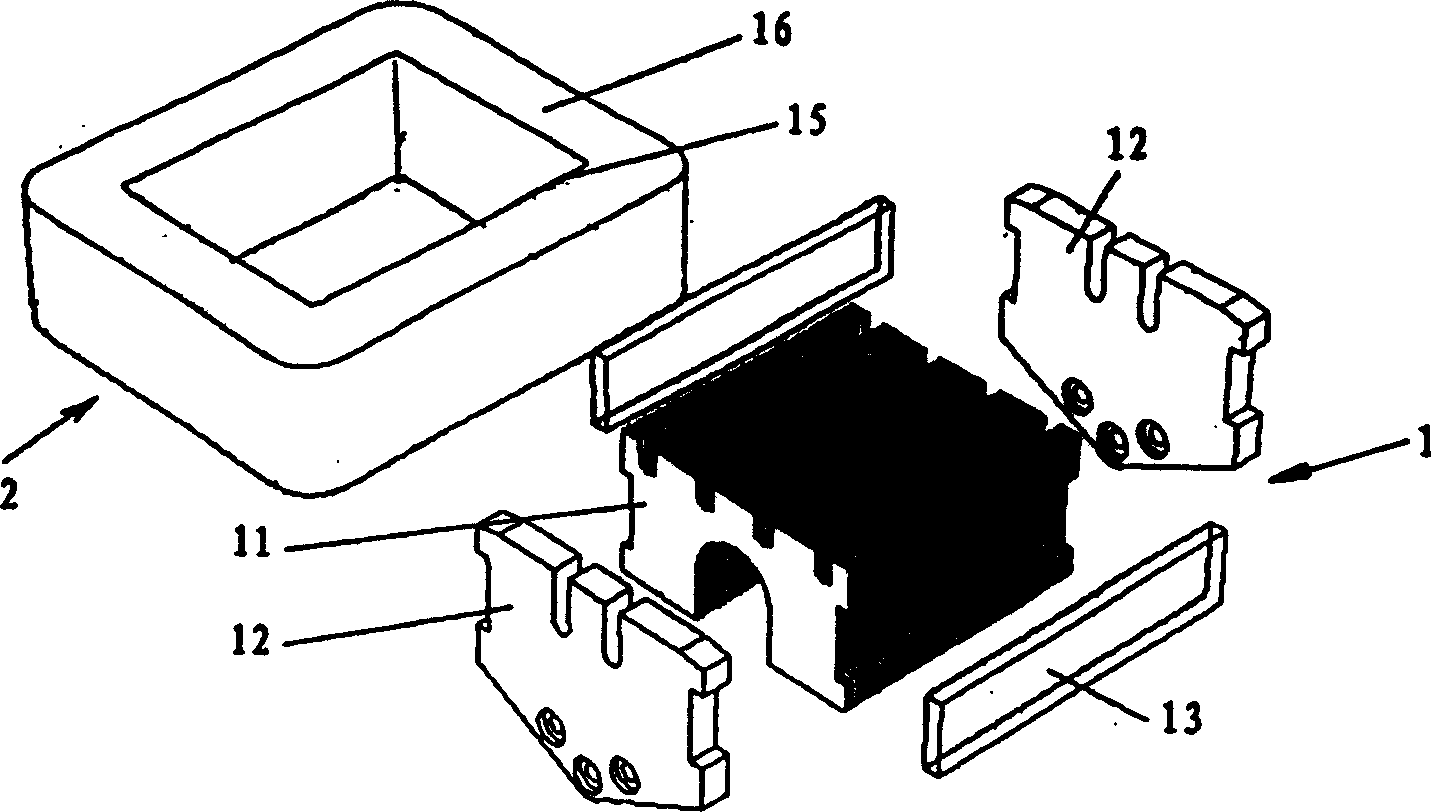

[0034] The present invention as image 3 As shown, it includes iron core 1 and suspension coil 2. This iron core 1 mainly is made up of chip 11, end plate 12, is provided with keyway 14 on the both sides of this chip 11, is also provided with keyway 14 at the corresponding position of both sides of end plate 12 equally, is provided with in this keyway 14 Numerous chips 11 and end plates 12 at both ends are connected into one pin key 13, and an insulating liner 17 is also provided between the pin key 13 and the keyway 14 (see Image 6 ) to prevent the chip 11 from forming a short circuit contact. The shape of this keyway 14 and the pin key 13 cross section that matches with it can be as Pic 4-1 a rectangle (including a square), or Figure 4-2 dovetail, or Figure 4-3 arc at both ends as shown, or any geometry that will ensure a tight fit for the chip. The multiple chips 11 and the two end plates 13 are fixedly connected into one body with screws at both ends of the end pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com