Pneumatic instrument for measuring inside diameter of thin-wall bearing

A technology of pneumatic measuring instruments and bearing rings, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of no effective measurement methods, achieve the effects of small human errors, high measurement accuracy, and avoid measurement marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention are described with reference to the accompanying drawings.

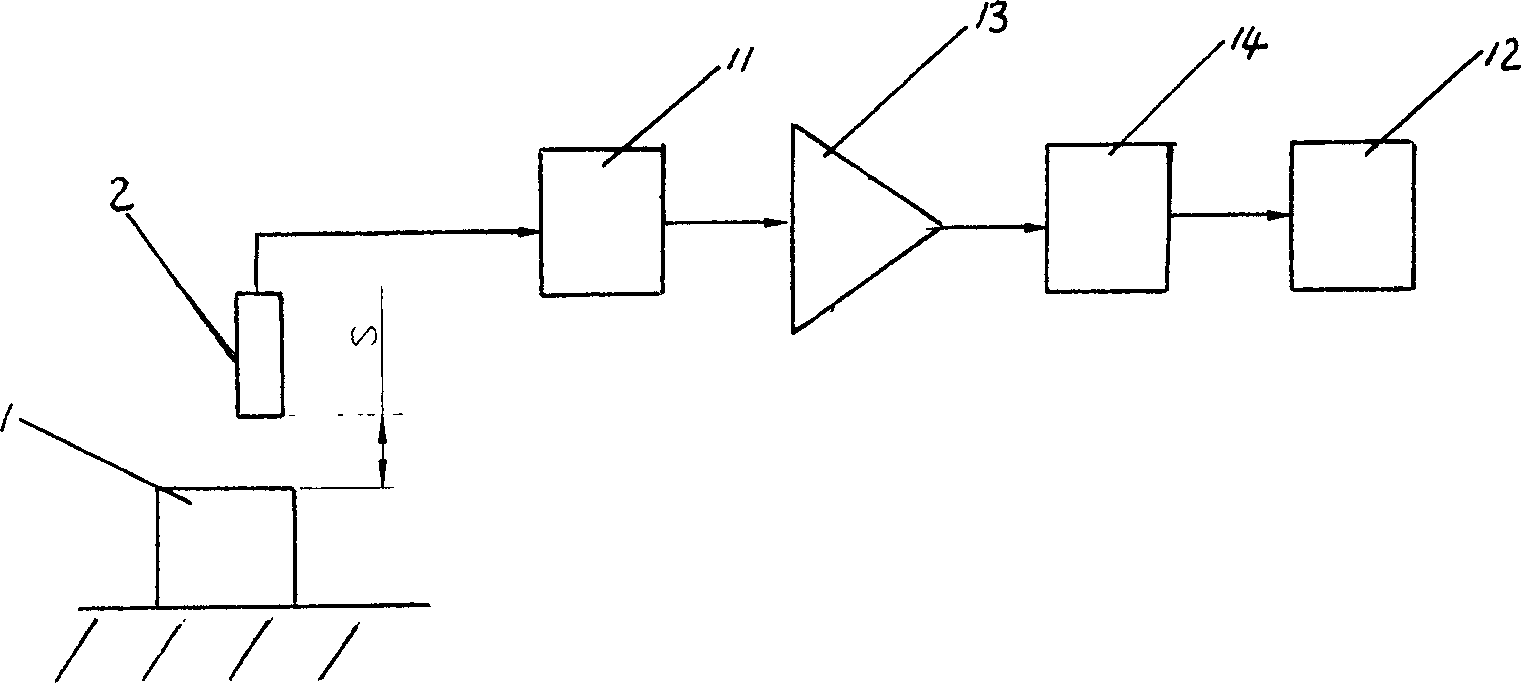

[0031] Such as figure 1 As shown, it mainly includes a gas-electric converter (existing) 11, an electronic display 12 (existing) and a pneumatic measuring head. The pneumatic measuring head adopts a cylindrical structure and is placed on a measuring device. Eight or more even-numbered nozzles 8 (eight are used in this embodiment), which spray compressed air through the nozzles to the inner diameter of the bearing ring 1 sleeved outside it, and the pneumatic measuring head 2 changes the air flow pressure into The change of the length value is converted by the gas-to-electric converter 11 , and the measured value is displayed on the electronic display through the amplifier 13 and the driving circuit 14 .

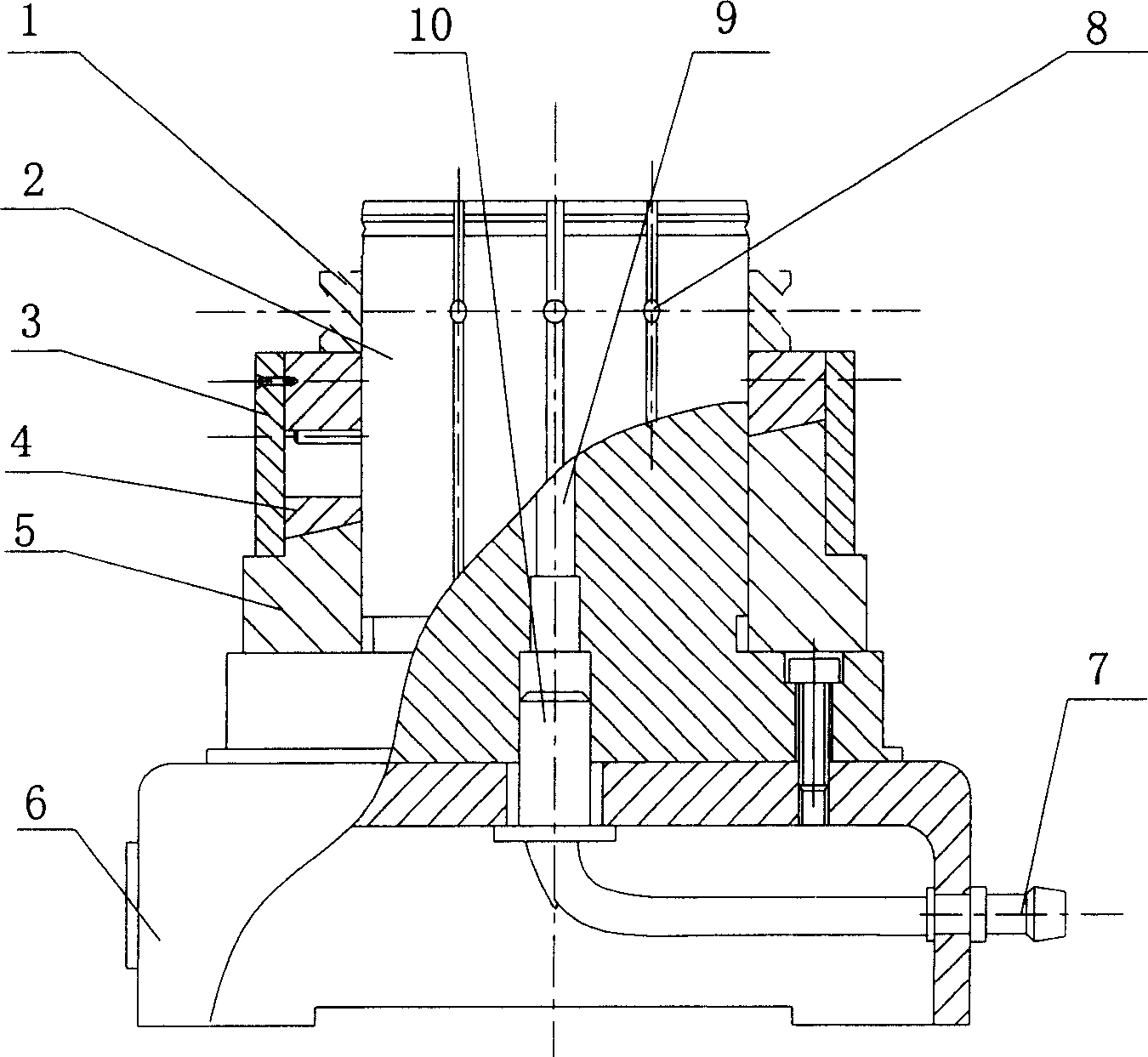

[0032] Such as figure 2 The measuring device package shown mainly includes a base 6 , an upper rotating disk 4 , and a lower rotating disk 5 . The lower rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com