Composite absorption material for removing arsenic from water and its prepn. method

A composite adsorption material and water removal technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effects of simple process, improved adsorption and arsenic removal efficiency, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

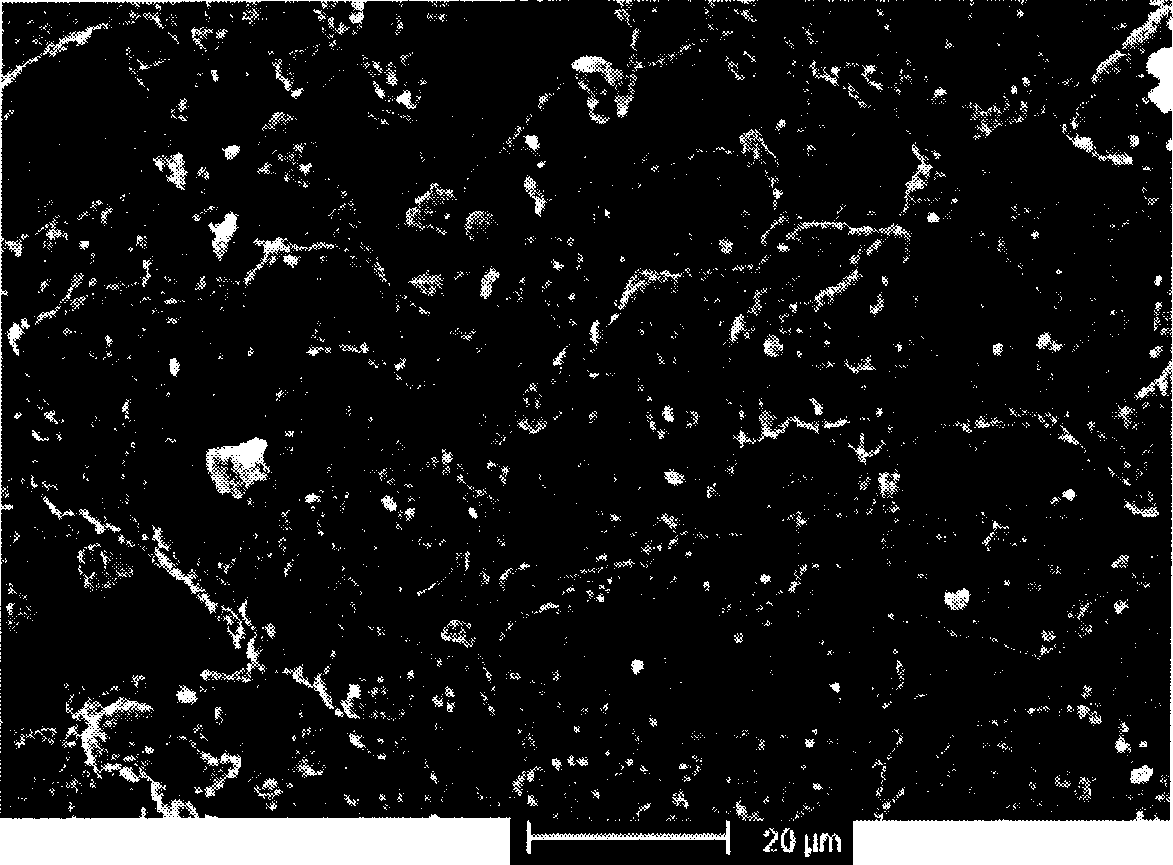

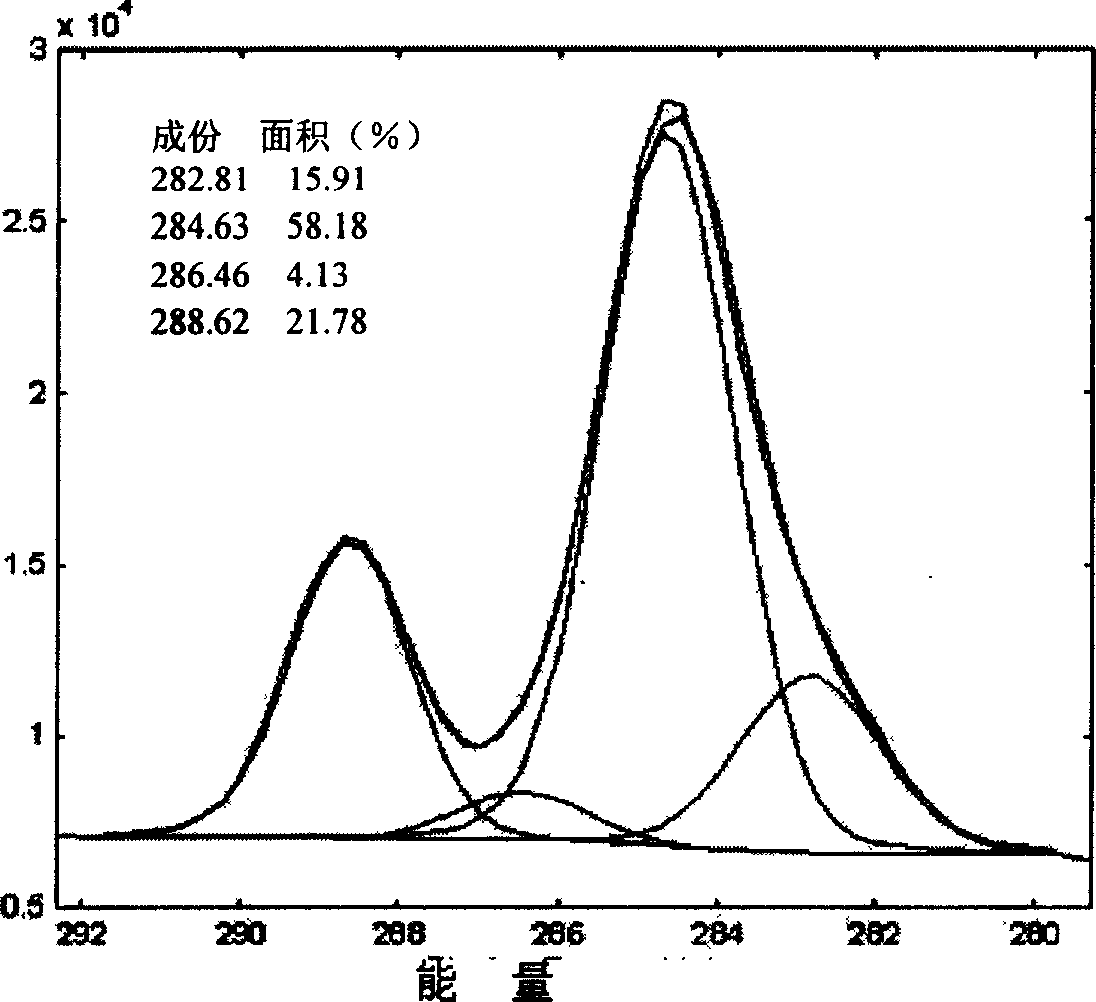

Image

Examples

Embodiment 1

[0023] The method for preparing composite adsorbent material (iron oxide / activated carbon) of the present invention is as follows:

[0024] The first step: activated carbon pretreatment, select the coal-based steam activation method activated carbon produced in Datong, the specification is 12X40, weigh two parts of activated carbon (one of which is used as a comparison), and put 20g of each part in two beakers, add to The ionized water was repeatedly washed three times, and the activated carbon after the water washing was put into a drying oven for drying (preserved at 90° C. for 24 hours) for use.

[0025] The second step: Activated carbon surface treatment, add one of the activated carbons treated in the first step to 1N100ml nitric acid (HNO 3 ) solution, stirred evenly, stood for 4 hours, washed three times with deionized water, and dried at 95-100°C for 24 hours before use.

[0026] The third step: preparation of iron oxide suspension, 7.2g of FeSO 4 ·7H 2 O and 9.8 g ...

Embodiment 2

[0029] The first step and the second step of preparing the composite adsorbent material of the present invention are the same as in Example 1.

[0030] The third step: the preparation of iron oxide suspension, 36g of FeSO 4 ·7H 2 O and 65g FeCl 3 ·6H 2 O is mixed and added to 80ml of water and heated to 60-70°C to completely dissolve, then add 80ml of NaOH with a concentration of 5mol / l, and stir rapidly to form iron oxide precipitate at a constant temperature of 70°C. Titrate with NaOH until the solution is basic (pH=9-11). Wash it with water to remove remaining salts. In order to prevent the flocculation and deposition of the product, effectively inhibit the growth of particles, and obtain fine particles with uniform distribution, add 1.6g of surfactant lauric acid, and add 6 drops of 5mol / l NaOH solution to increase its solubility. Stir for 10 minutes (min), put it into a container and heat to 90°C, and keep the temperature constant for 30min. Add HCl to adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com