Fast involute grounding switch with ultrahigh-voltage

A grounding switch, UHV technology, applied in the field of involute UHV fast grounding switch, can solve the problems of slow closing action, influence stability, equipment damage, etc., achieve low starting power, reduce damage, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

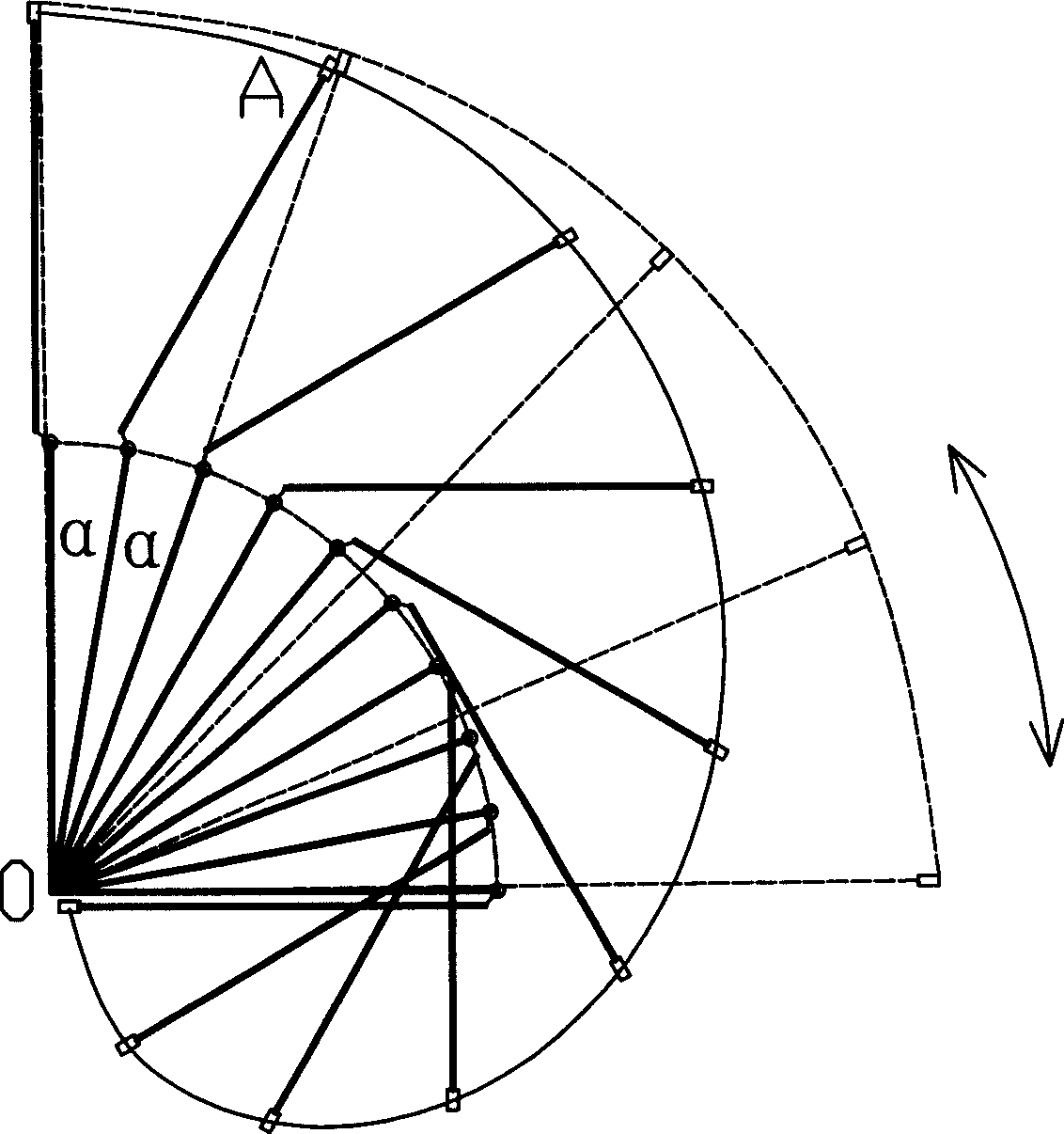

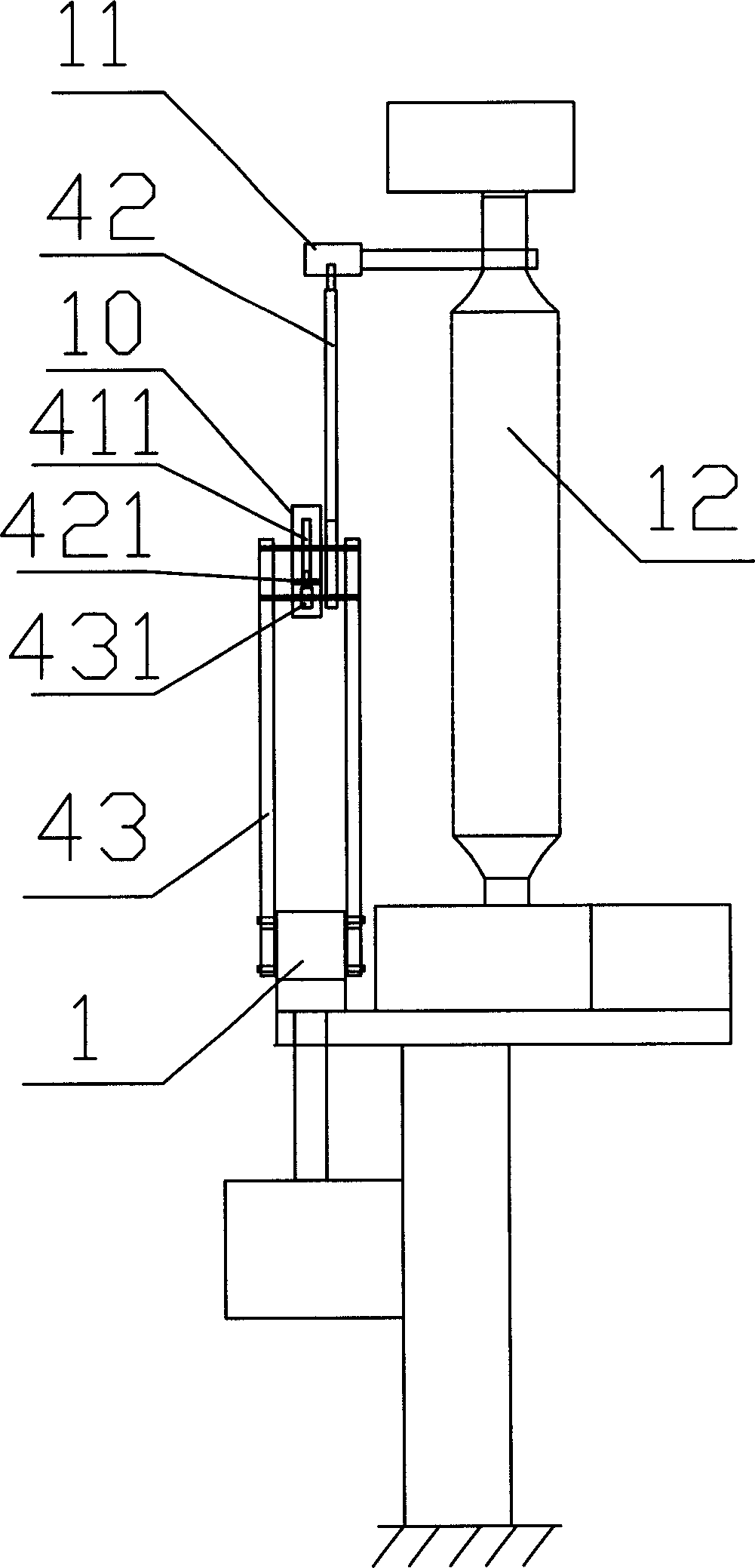

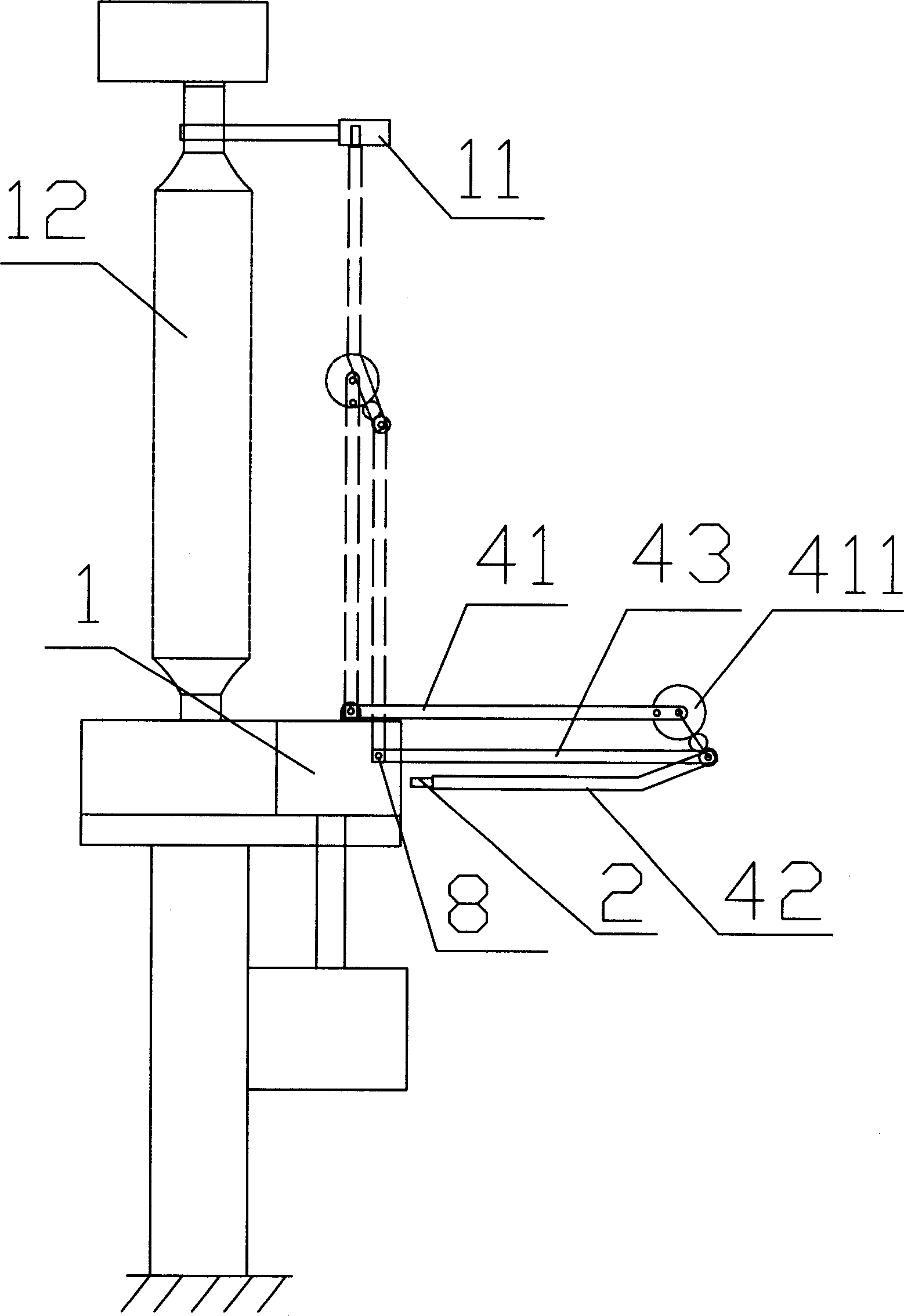

[0017] Such as image 3 As shown, the involute type UHV quick grounding switch of the present invention includes a gear box 1 installed on the base, the gear box 1 is connected with the power unit, and the power output shaft of the gear box 1 is fixedly installed with a connecting Rod, the top of the connecting rod has a moving contact 2. The connecting rod includes an auxiliary arm 41 and a driving arm 43 hinged on the gearbox in a parallel manner, a folding arm 42 hinged on the top of the auxiliary arm 41 and the driving arm 43 , and the transmission case 10 . The end of the driving arm 43 is fixedly connected on the power output shaft 8, and the end of the auxiliary arm 41 is hinged on the gear box; the transmission box 10 is provided with a driving gear 411, a driven gear 431 and an intermediate gear 421, and the intermediate gear 421 is connected with the driving gear simultaneously. Gear 411 meshes with driven gear 431. Meanwhile, the top of auxiliary arm 41 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com