Gypsum pulp dewatering device and method for wetting smoke desulfurizing system

A technology of wet flue gas desulfurization and dehydration equipment, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve the effects of reducing system size, solving water balance, and reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

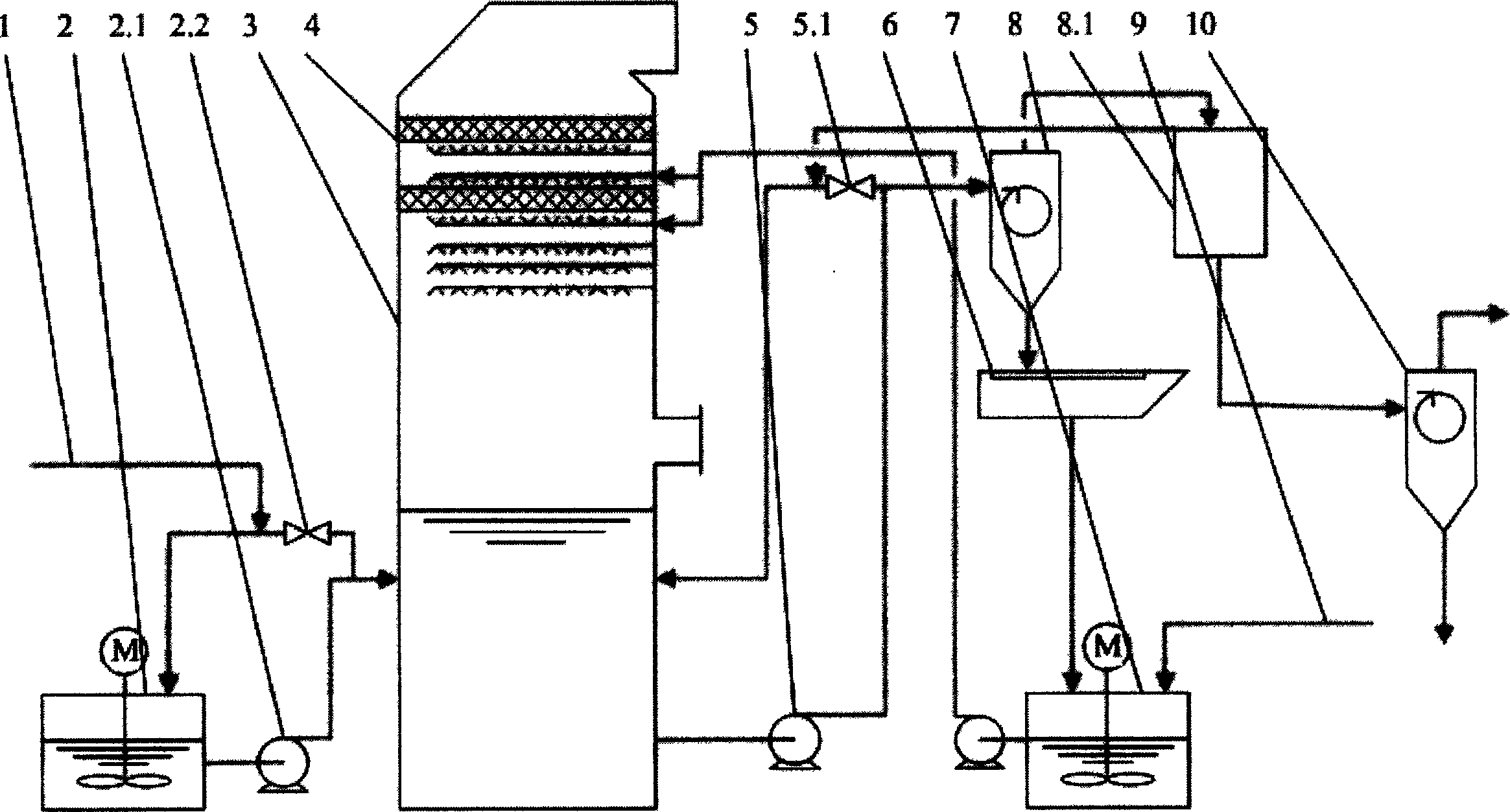

[0015] The gypsum slurry dehydration system and the limestone slurry conveying system of the present invention are composed of a limestone slurry tank 2, a limestone slurry pump 2.1, a limestone slurry return control valve 2.2, an absorption tower 3, a gypsum slurry discharge pump 5, and a gypsum slurry discharge pump return pipe control valve 5.1 , a vacuum belt conveyor 6, a filtrate tank 7, a gypsum cyclone 8, an overflow tank 8.1, and a waste water cyclone 10; wherein, the lower half of the limestone slurry tank 2 passes through the lower half of the limestone slurry pump 2.1 and the absorption tower 3 The pulping process water 1 is connected to the upper half of the limestone slurry tank 2 and communicates with the lower half of the absorption tower 3 through the limestone slurry backflow regulating valve 2.2; the upper part of the absorption tower 3 is provided with a demister 4 , the inlet of the gypsum slurry discharge pump 5 is connected to the lower half of the absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com